Revision 1.0

13

5.2

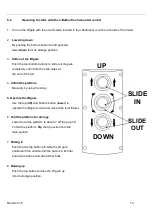

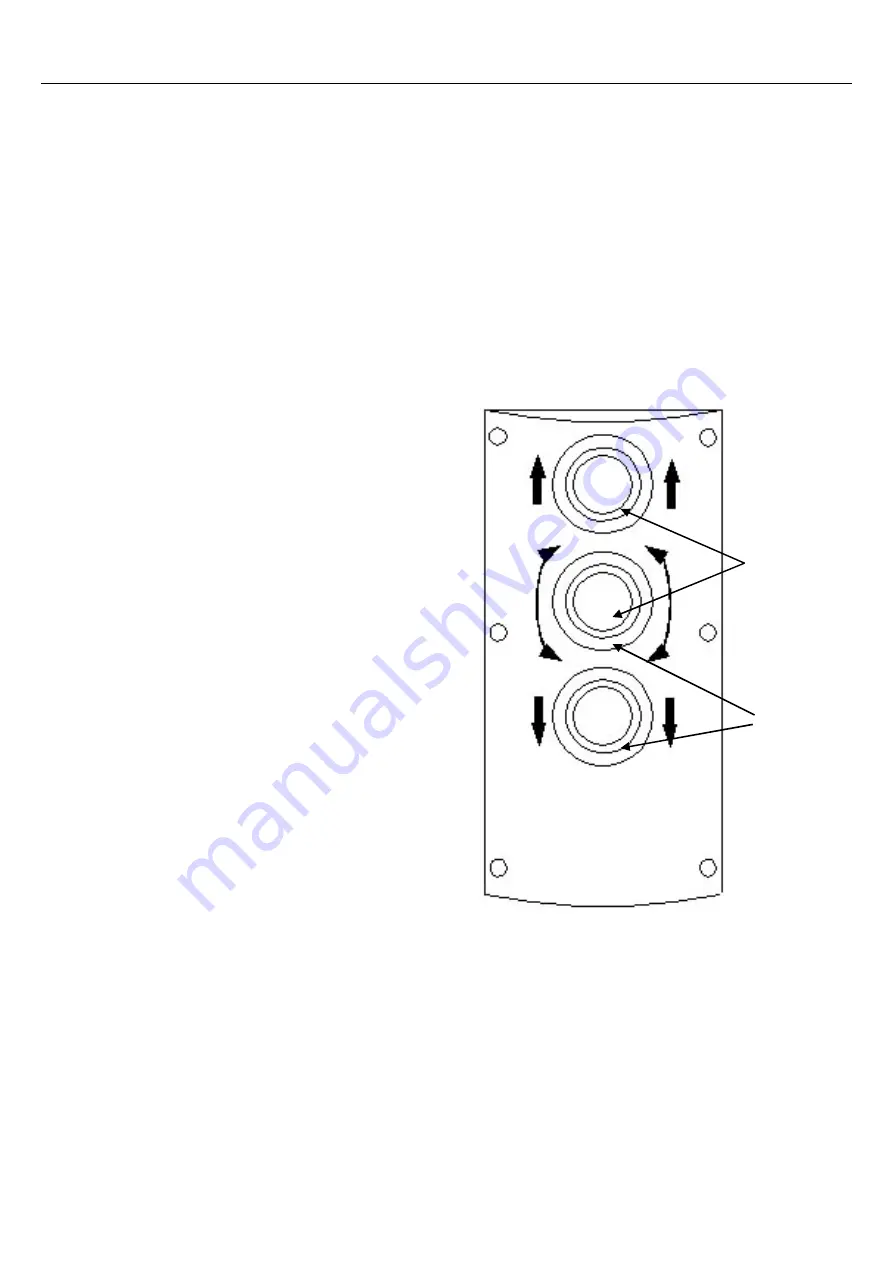

Operating the ILSL with the 3-Button flush mounted control

1. Turn on the liftgate with the on/off switch located in the cab(trucks) or at the curb side of the trailer

2. Lowering down

By pushing the bottom button the lift gate will

lower down from its storage position.

3. Slide out the liftgate

Push the two bottom buttons to slide out the gate

completely until it hits the slide stops at

the end of the rail

4. Unfold the platform

Manually by using the strap

5. Operate the liftgate

Use the top (lift) and bottom button (lower) to

operate the liftgate to load and unload the truck/trailer

6. Fold the platform for storage

Lower down the platform to about 3” off the ground.

To fold the platform, flip the tip section onto the

main section.

7. Sliding in

Push the two top buttons to slide the lift gate

underneath the vehicle until the gate is in its final

position and does not slide further back.

8. Raising up

Push the top button to raise the lift gate up

into its storage position.

SLIDE

OUT

UP

SLIDE

IN

DOWN