- 23 -

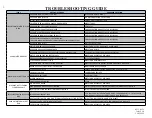

TROUBLESHOOTING GUIDE

ISSUE

POTENTIAL CAUSE

PROPOSED SOLUTION

INSUFFICIENT WATER TO SCRUB

HEAD

SOLUTION FLOW SETTING IS TOO LOW

ADJUST SOLUTION CONTROL

SOLUTION TANK IS EMPTY

ADD WATER/SOLUTION TO THE TANK

IN-LINE SOLUTION FILTER IS CLOGGED

REMOVE AND CLEAN THE FILTER

SOLUTION TUBE IS CLOGGED, KINKED, OR DAMAGED

INSPECT TUBES

SOLUTION SHUT OFF VALVE IS CLOSED

OPEN VALVE

PUMP OR PUMP WIRES ARE DAMAGED

VERIFY OPERATION AND REPLACE IF NECESSARY

OPERATOR CONTROL BOARD IS DAMAGED

VERIFY OPERATION AND REPLACE IF NECESSARY

SOLUTION SOLENOID VALVE MAY BE FAULTY

VERIFY OPERATION AND REPLACE IF NECESSARY

CHEMICAL INJECTION PUMP IS NOT RUNNING

* ONLY ON MACHINES WITH OPTIONAL CHEMICAL INJECTION SYSTEM

VERIFY OPERATION AND REPLACE IF NECESSARY

POOR WATER RECOVERY

RECOVERY TANK IS FULL

EMPTY RECOVERY TANK

DIRTY OR WORN SQUEEGEE BLADES

INSPECT AND ROTATE OR REPLACE AS REQUIRED

RECOVERY HOSE LOOSE OR DAMAGED

INSPECT AND REPAIR

RECOVERY HOSE OR SQUEEGEE ASSEMBLY HAS AN OBSTRUCTION

CLEAR OBSTRUCTIONS FROM RECOVERY SYSTEM

DIRTY OR WORN SIDE SQUEEGEE BLADES

INSPECT AND REPLACE AS REQUIRED

SQUEEGEE ASSEMBLY MAY BE OUT OF ADJUSTMENT

ADJUST AS NECESSARY

STUCK OR DAMAGED BALL FLOAT

INSPECT AND REPAIR/REPLACE

RECOVERY TANK LID IS NOT SEALING PROPERLY

INSPECT RECOVERY LID GASKET. REPAIR OR REPLACE IF NEEDED

DRAIN HOSE CAP IS NOT INSTALLED PROPERLY

INSTALL DRAIN HOSE SECURELY

CLOGGED HEPA FILTER

REMOVE AND INSPECT INSIDE AND OUTSIDE OF HEPA FILTER

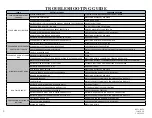

MACHINE WILL NOT TURN ON

FAULTY KEY SWITCH

DIAGNOSE AND REPLACE

DISCHARGED BATTERIES

CHARGE BATTERIES

BLOWN MAIN FUSE

INSPECT AND REPLACE AS REQUIRED

LOOSE OR DAMAGED WIRE

REPAIR

MACHINE NOT CLEANING

FLOOR PROPERLY

WORN PAD OR BRUSH

INSPECT AND REPLACE AS REQUIRED

WRONG PAD OR BRUSH FOR APPLICATION

CONTACT YOUR LOCAL DISTRIBUTOR FOR RECOMMENDED APPLICATION

INSUFFICIENT CLEANING SOLUTION FOR APPLICATION

ADJUST THE MIXTURE AS REQUIRED

EXCESSIVE FOAM IN RECOVERY

TANK

IMPROPER DETERGENT TYPE

USE A LOW-FOAM DETERGENT OR ADD A DE-FOAMING AGENT TO THE RECOVERY

TANK. READ ALL CHEMICAL LABELS THOROUGHLY BEFORE USE

MIXTURE SETTING TOO HIGH ON OPTIONAL CHEMICAL INJECTION SYSTEM ADJUST TO A LOWER RATIO AND/OR FLOW RATE

VACUUM MOTOR WILL NOT

RUN

VACUUM SWITCH OR WIRING MAY BE FAULTY

CONTACT SERVICE TECHNICIAN TO TROUBLESHOOT AND ISOLATE

FAULTY MAIN CONTROLLER

INSPECT AND REPLACE AS REQUIRED

Содержание RS28

Страница 23: ...20 RETURN TO TABLE OF CONTENTS PAGE INTENTIONALLY LEFT BLANK...

Страница 43: ...RETURN TO TABLE OF CONTENTS 40 PAGE INTENTIONALLY LEFT BLANK...

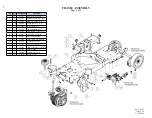

Страница 52: ...49 RETURN TO TABLE OF CONTENTS ELECTRICAL DIAGRAMS...

Страница 53: ...RETURN TO TABLE OF CONTENTS 50 ELECTRICAL DIAGRAMS...

Страница 54: ...RETURN TO TABLE OF CONTENTS 51 DATE MAINTENANCE LOG...

Страница 55: ...52 RETURN TO TABLE OF CONTENTS DATE MAINTENANCE LOG...

Страница 57: ...54 RETURN TO TABLE OF CONTENTS PAGE INTENTIONALLY LEFT BLANK...

Страница 58: ...www pacificfloorcare com...