F o r m X X X X : R e v i s e d 2 0 1 8

Page 4

should be inspected and tested no less than weekly to determine the condition of the machine. Necessary

maintenance or repair of both shall be performed and completed before the machine is operated. The

EMPLOYER shall maintain records of these inspections and the maintenance work performed.

Our Company is not responsible to notify the user of this equipment of future changes in State or Federal

laws, or construction

standards.

1.3

Warranty Program

We warrant our new parts against defects under normal use and service for a period of 12 months after date

of shipment. Our obligation under this warranty is limited to replacing or repairing (at our option) the

defective part without charge, F.O.B. our plant in Bloomfield, Connecticut. The defective part must be

forwarded to our plant, freight prepaid, for our inspection prior to replacement or repair

. EXCEPT AS

EXPRESSLY PROVIDED HEREIN, THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING A WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

Furthermore, the seller does not warrant or represent that the equipment complies with the provisions of any

law, particularly including the Occupational Safety and Health Act of 1970, and regulations promulgated there

under. In no event shall we be liable for special, indirect incidental or consequential damages, however rising.

1.4

Receiving and Inspection

SPECIAL NOTE

: P/A INDUSTREIS INC. ASSUMES NO RESPONSIBILTIY IN CONNECTION HEREWITH, NOR CAN IT

BE ASSUMED THAT ALL ACCEPTABLE SAFETY MEASURES ARE CONTAINED IN THIS PUBLICATION, OR THAT

OTHER ADDITIONAL MEASURES MAY NOT BE REQUIRED UNDER PARTICULAR OR EXCEPTIONAL

CIRCUMSTANCES OR CONDITIONS.

RECEIVING INSPECTION

Before removing the unit from its packaging, check for visual damage, especially if crate, skid,

or carton had been damaged in transit. Any damage caused by shipping should be immediately

reported to the carrier. If the unit appears in satisfactory condition, remove all the packaging.

Read these instructions. They are provided to answer questions regarding the Operation and

use of this equipment.

Содержание SRH10K-24

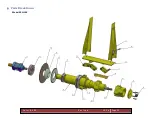

Страница 15: ...F o r m X X X X R e v i s e d 2 0 1 8 Page 15 6 Parts Break Down Model SRH 10K...

Страница 16: ...F o r m X X X X R e v i s e d 2 0 1 8 Page 16 Model SRH 12k...

Страница 17: ...F o r m X X X X R e v i s e d 2 0 1 8 Page 17 Model SRH 15K...

Страница 18: ...F o r m X X X X R e v i s e d 2 0 1 8 Page 18 Hydraulic Hold Down Arm Option...

Страница 19: ...F o r m X X X X R e v i s e d 2 0 1 8 Page 19 Hydraulic Coil Cart Option...

Страница 20: ...F o r m X X X X R e v i s e d 2 0 1 8 Page 20 Stock Reel Body...