23

OPERATION (cont).

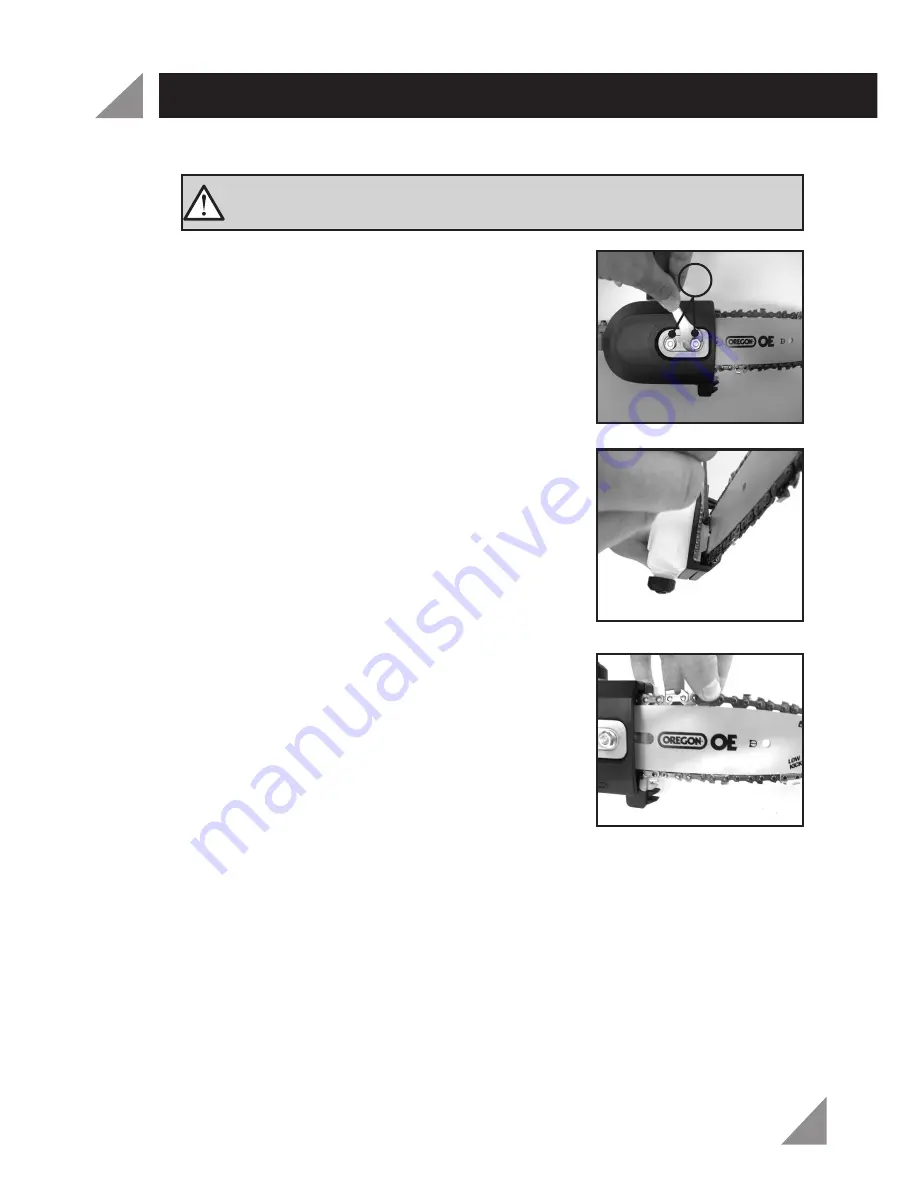

1. Loosen the two chain drive cover nuts (c)

with small open-end spanner (20) (Fig. 30).

Caution:

If you try to rotate the chain tension

screw whilst the chain drive nuts are tight,

it will result in the chain not loosening and

possible damage to the chain tensioning

screw and the chain tensioning pin.

2. Turn the chain tensioning screw clockwise

so that the chain is correctly tensioned

(Fig. 31)

3. To get the correct chain tension, firmly

pull up on the chain at the middle of the

top of the exposed guide bar. When the

chain is pulled up to its highest point,

the bottom tip of the links should only

just stay in the track [middle of the guide

bar] (Fig. 32).

Fig.30

Fig.31

Fig. 32

Chain Tension

4. Once the correct tension has been achieved tighten the chain

drive cover nuts to lock the bar and tension in place.

5. Check the tension again after a few minutes of cutting and

several times in the first hour because the chain will lengthen as

it breaks in. Adjust as you go. A loose chain causes rapid wear

to both the chain and the guard bar and could derail causing a

major safety hazard.

Note:

Chains lengthen slightly as the link pins set into place. They

set into place from the load applied to the chain, this process

continues through-out the life of all chains as they gradually wear

from use.

WARNING!

The chain has sharp edges. For your safety,

please use work gloves.

c