7.

- Ma

i

nten

ance

Must check how tighten the bolts are after the first 2 hours of labor, specially

the

ones on the bodies and shares.

Afterwards, check every 100 hours of labor. When

finishing the campaign, wash

the plough and grease the bodies to avoid rust.

Lube

: Greasing points must be greased up regularly.

Safe maintenance

Get familiar with the maintenance proccedures before doing any labor.The

working

area must be clean and dry. Not doing any greasing labor, repair or

adjustment

while the engine is running. Keep the hands, feets, and clothes

always far from the

moving components. Place all the hydraulic controls on

neutral-gear in order to

relieve pressure. Lower all gear to the ground.

All the components must be in good

shape and correctly installed. Repair

damage immediately. Change any wasted or

broken piece. Keep all the

components of the machine clean off of grease, oil and

accumulated dirt.

By dealing with trailed equipment, disconnecting the group of

cables from the

tractor before doing any wielding on the machine.

Watch out for the high pressure leaks

Leaking fluids from the system might leak strong enough to tear flesh, causing

severe injuries. Therefore, is indispensable to leave the system pressure-less

before loosing or disconnecting any pipe and assure that all the connections and

connectors are well-tighten before applying pressure to the system.

In order to locate an hydraulic oil leak use a piece of cardboard placed in

between the connections. Don't get near high-pressure leakings.

Even if after all this measures an accident happens, go immediately to see a

doctor, who should remove the fluid surgically in a few hours in order to avoid

gangrene. Unexperienced doctors with injuries of such nature may go to a

specialized medical center.

Maintenance of hydraulic cylinders.

IMPORTANT

: keep the plugs clean. Abrasive

particles, such as sand, metal sharps, may damage the cylinders, causing inner

leaks. Once unplugged off the tractor, place the protection bolts and make

sure they're not touching the ground.

14

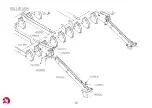

LINKING

BOLTS

The

linking

bolts

A

and

the

turning

bolt

B

must be made of

: F-125

TREATED

of

36

and

40

diameter each

.

For

the

proper

a

d

just

m

e

nt

and

func

t

ion

ing

the

bolts

will be

replaced

when

the

clearance

between

the

bolt

and

the

holder

overpass

2 mm.

A

B

Содержание Eurodisc

Страница 1: ...EURODISC REV JUL 2021 INSTRUCTIONS AND SPARE PARTS MANUAL ...

Страница 17: ...Fig 15 Fig 16 Fig 17 Fig 18 16 ...

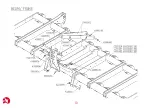

Страница 20: ...19 BEAM FRAME ...

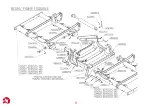

Страница 22: ...21 BEAM FRAME FOLDABLE ...

Страница 24: ...23 HYDRAULIC SYSTEM EURODISC ...

Страница 26: ...25 HYDRAULIC SYSTEM EURODISC ...

Страница 28: ...27 BODY ...

Страница 30: ...29 ROLLER ARM ...

Страница 32: ...31 ROLLER ...

Страница 36: ...35 DOUBLE ROLLER ...

Страница 38: ...37 V ROLLER ...

Страница 40: ...39 RUBBER ROLLER ...

Страница 42: ...41 LEAF SPRINGS ROLLER ...

Страница 44: ...43 T RING ROLLER ...

Страница 48: ...47 REAR DEFLECTORS ...

Страница 50: ...49 POSITIONING OF DEFLECTORS ...

Страница 51: ...50 ...

Страница 52: ...51 SIDE DISC ...

Страница 54: ...53 LATERAL WHEELS ...

Страница 56: ...55 FIX EURODISC TRAFFIC LIGHT KIT ...

Страница 58: ...57 FOLDABLE EURODISC TRAFFIC LIGHT KIT ...

Страница 60: ...59 FRONT TRAILING KIT ...

Страница 62: ...61 FOLDING AUTOMATIC LOCKER ...

Страница 64: ...63 REAR TRAILING KIT ...

Страница 66: ...65 HYDRAULIC SYSTEM TRAILING KIT ...

Страница 68: ...67 FRONT WHEEL EURODISC 21 ...

Страница 70: ...69 FRONT WHEEL EURODISC 21 ...

Страница 72: ...71 FRONT SIGNALING KIT ...

Страница 74: ...73 REAR SIGNALING KIT ...