3

Name Description

Electromagnetic brake

terminals

(CN1-MB1/MB2)

Connects the lead wires of "cable for

electromagnetic brake" (for the

EAS

Series

only).

MB1: Electromagnetic brake

−

(black)

MB2: Electromagnetic brake + (white)

Power supply input

terminals (CN1)

Connects a main power supply of the

driver.

+: +24 VDC/48 VDC power supply input

−

: power supply GND

Frame Ground

Terminal (CN1)

Ground using a wire of AWG24 to 16 (0.2

to 1.25 mm

2

).

Motor connector (CN2) Connects the actuator.

Data edit connector

(CN3)

Connects a PC in which the

MEXE02

has

been installed, or the

OPX-2A

.

Battery connector

(CN4)

Connects an accessory battery

BAT01B

(sold separately).

Sensor signal

connector (CN5)

Connects the limit sensor.

RS-485 communication

connectors (CN6/CN7)

Connects the RS-485 communication

cable.

Input signal connector

(CN8)

Connects the input signals.

Output signal

connector (CN9)

Connects the output signals.

DIN lever

Installs the driver to DIN rail.

Installation

Location for installation

The driver has been designed and manufactured to be installed

within another device. Install them in a well-ventilated location that

provides easy access for inspection.

The location must also satisfy the following conditions:

•

Inside an enclosure that is installed indoors (provide vent holes)

•

Operating ambient temperature 0 to +50 °C (+32 to +122 °F)

(non-freezing)

•

Operating ambient humidity 85% or less (non-condensing)

•

Area that is free of explosive atmosphere or toxic gas (such as

sulfuric gas) or liquid

•

Area not exposed to direct sun

•

Area free of excessive amount of dust, iron particles or the like

•

Area not subject to splashing water (rain, water droplets), oil (oil

droplets) or other liquids

•

Area free of excessive salt

•

Area not subject to continuous vibration or excessive shocks

•

Area free of excessive electromagnetic noise (from welders,

power machinery, etc.)

•

Area free of radioactive materials, magnetic fields or vacuum

•

1000 m (3300 ft.) or lower above sea level

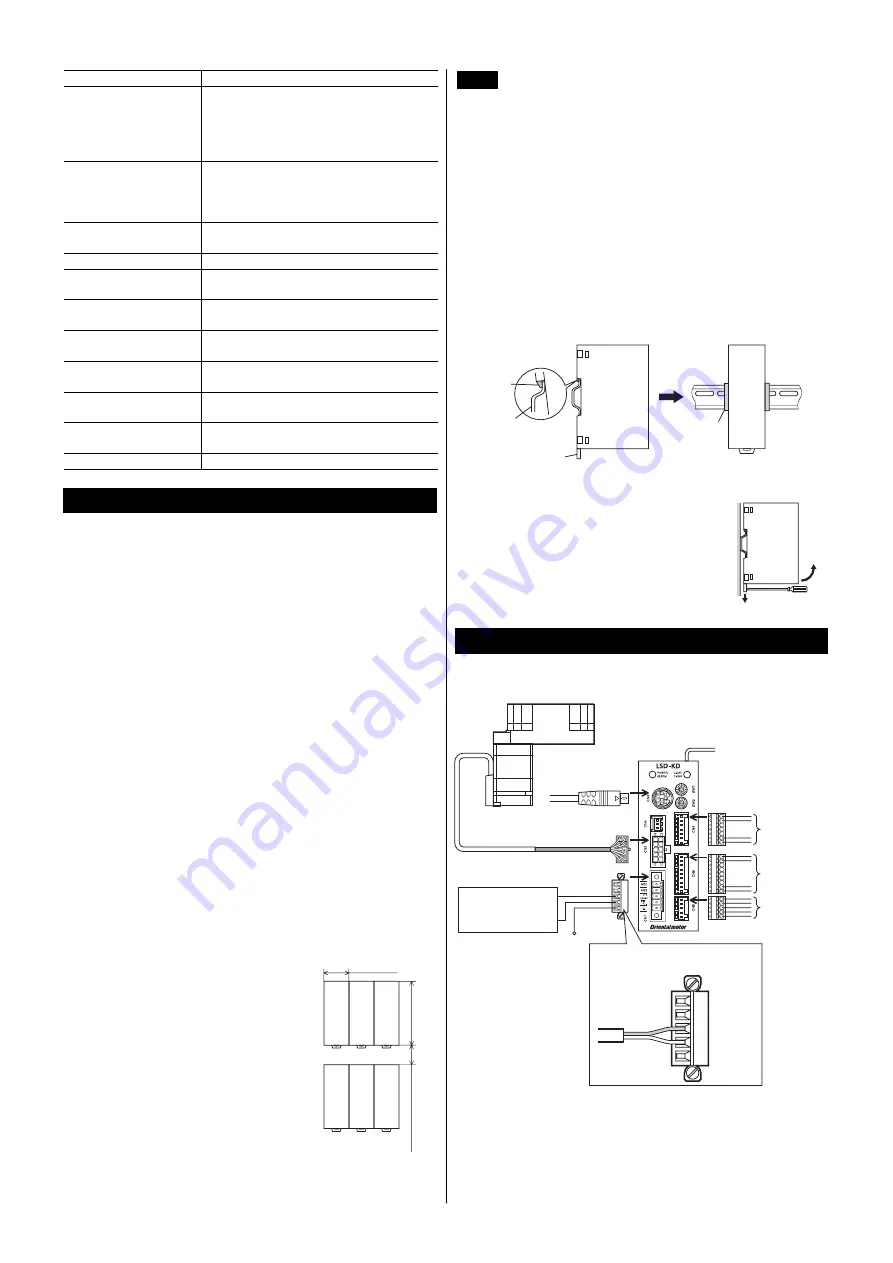

Installation method

Mount the driver to a 35 mm (1.38 in.) width

DIN rail. When installing two or more drivers

in parallel, it is possible to install them

closely in the horizontal direction.Provide a

minimum clearance of 50 mm (1.97 in.) in

the vertical direction.When installing three or

more drivers closely, the heat generation of

the inside drivers become high. Install the

less frequently used drivers toward the inside.

35 (1.38)

50 (1.97) or more

100 (3.94)

[Unit: mm (in.)]

Note

•

Install the driver in an enclosure whose pollution

degree is 2 or better environment, or whose degree

of protection is IP54 minimum.

•

Do not install any equipment that generates a large

amount of heat or noise near the driver.

•

Do not install the driver underneath the controller or

other equipment vulnerable to heat.

•

If the ambient temperature of the driver exceeds

50 °C (122 °F), improve the ventilation condition

such as providing forced cooling by using fans or

creating spaces between the drivers.

•

Be sure to install the driver vertically (vertical

position).

Pull down the driver’s DIN lever and lock it. Hang the hook at the

rear to the DIN rail, and push in the driver. After installation, secure

the both sides of the driver with the end plate.

Hook

DIN rail

DIN lever

㪜㫅㪻㩷㫇㫃㪸㫋㪼

Removing from DIN rail

Pull the DIN lever down until it locks using a flat

tip screwdriver, and lift the bottom of the driver

to remove it from the rail. Use force of about 10

to 20 N (2.2 to 4.5 lb.) to pull the DIN lever to

lock it. Excessive force may damage the DIN

lever.

Connection

Connection example

•

•

•

•

•

•

•

•

+24 VDC±5%

Cable for motor

Motor cable

+

GND

FG

Pay attention to the

polarity of the power

supply.

+24 VDC

GND

∗

2

∗

1

CN9:

Output signals

CN6/7: RS-485

Communication cable

CN8:

Input signals

CN5:

Sensor inputs

CN3

䋺

OPX-2A

or

MEXE02

CN2

CN1: DC power input

∗1

Power supply and FG connection cable: AWG24 to 16 (1.25to 0.2 mm2)

∗2

I/O signals connection cable: AWG26 to 20 (0.5to 0.14 mm2)