14

Running/stopping the motor

Run/stop the motor by inputting operation control signals.

•

z

Operation

Since signals required to operate the motor are assigned to the control inputs

of the CN5, it is possible to perform operation without any change from

factory default.

CN5

Pin No.

Name

Initial value

Description

1

IN0 FWD input

This signal is used to rotate

a motor in the clockwise

direction.

2

IN1

REV input

This signal is used to rotate a

motor in the counterclockwise

direction.

3

IN2

STOP-MODE input

This signal is used to select

how to stop the motor.

•

When the FWD input is turned ON, the motor rotates in the clockwise

direction. When the FWD input is turned OFF, the motor stops.

•

When the REV input is turned ON, the motor rotates in the

counterclockwise direction. When the REV input is turned OFF, the motor

stops.

•

If both the FWD input and REV input are turned ON, the motor stops

instantaneously.

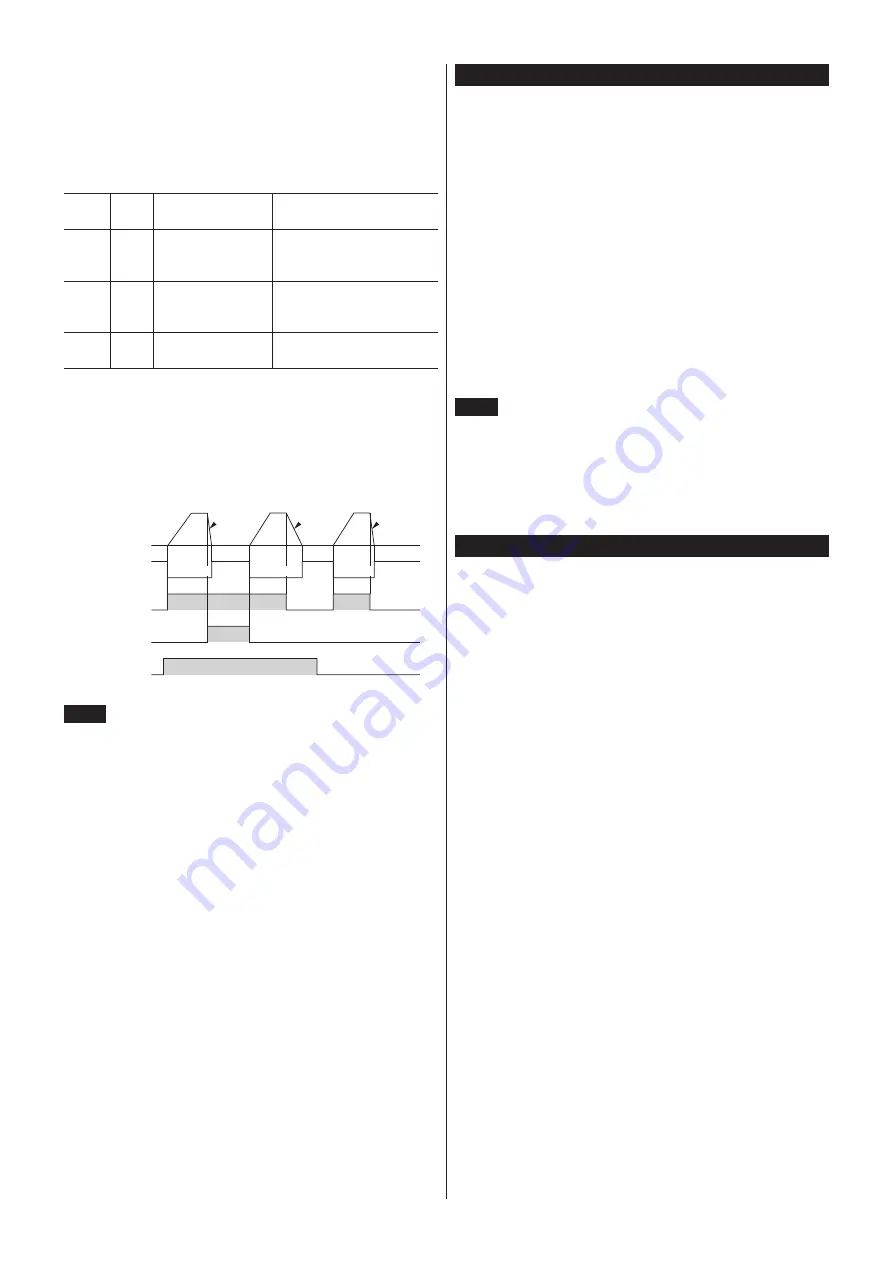

ON

OFF

ON

OFF

ON

OFF

STOP-MODE

input

REV input

FWD input

Motor operation

Deceleration

stop

Instantaneous

stop

Instantaneous

stop

Electromagnetic

brake operation

Release

Release

Release

Note

When using the motor in vertical drive (gravitational

operation), although it depends on the load condition, if

operation is performed with the setting below, the motor

shaft may momentarily rotate in the reverse direction (about

one-fourth revolution of the motor output shaft) at the time of

starting/stopping the motor.

• When the set rotation speed is low

• When the acceleration time and deceleration time is long

•

z

Stop

When the STOP-MODE input is ON, the motor decelerates to a stop. When

the STOP-MODE input is OFF, the motor stops instantaneously.

Inspection

It is recommended that periodic inspections for the items listed below are

conducted after each operation of the motor.

If an abnormal condition is noted, discontinue any use and contact your

nearest Oriental Motor sales office.

Inspection item

•

The motor/gearhead mounting screws are not loose.

•

Check for any unusual noises in the motor bearings (ball bearings) or other

moving parts.

•

The bearing (ball bearing) and gear meshing parts of the gearhead are not

generating noise.

•

The motor/gearhead output shaft is not misaligned with the load shaft.

•

Are there any scratches, signs of stress or loose driver connections in the

cable?

•

Are the openings in the driver blocked?

•

The driver mounting screws and power connection terminal screws are not

loose.

•

Are there any strange smells or appearances within the driver?

Note

•

Conduct the insulation resistance measurement or dielectric

strength test separately on the motor and the driver.

Conducting the insulation resistance measurement or

dielectric strength test with the motor and driver connected

may result in damage to the product.

•

The driver uses semiconductor elements, so be extremely

careful when handling them.

Related products (sold separately)

Network converter

NETC01-CC

(CC-Link Ver.1.1 compatible)

NETC02-CC

(CC-Link Ver.2 compatible)

NETC01-M2

(MECHATROLINK-

Ⅱ

compatible)

NETC01-M3

(MECHATROLINK-

Ⅲ

compatible)

NETC01-ECT

(EtherCAT compatible)

When the

BLE

Series

FLEX

RS-485 communication type is used in a

CC-Link system or MECHATROLINK system, EtherCAT system while

connecting the driver via the network converter, the converted data from the

each communication protocol to the RS-485 communication protocol can be

sent to the driver.

Alarms and other data output from the driver, which normally conform

to the RS-485 communication protocol, can also be converted to each

communication protocol and sent to the master station accordingly.