10

Connection

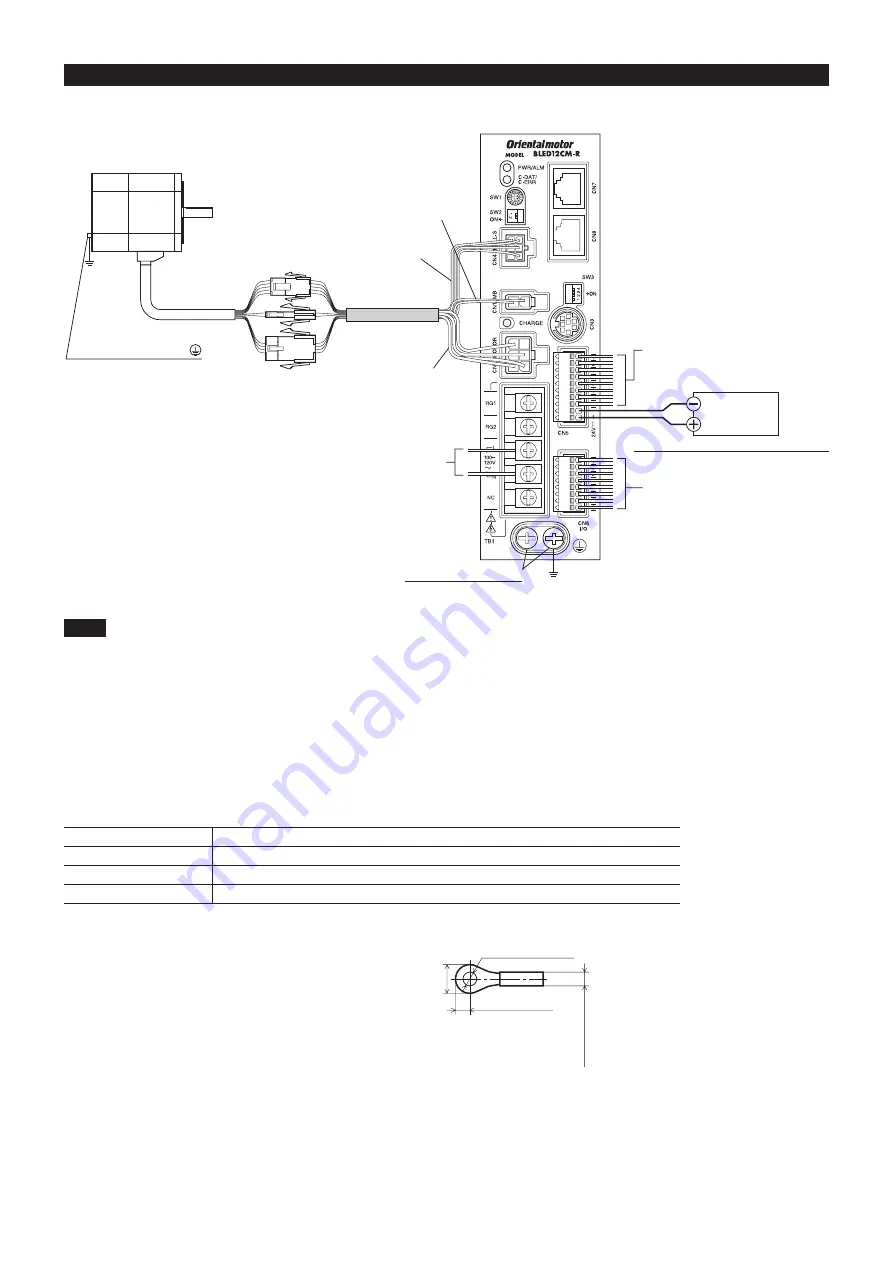

Connection example (electromagnetic brake motor)

24 VDC

power supply

Motor signal connector

Connect to CN4

Motor power connector

Connect to CN2

Electromagnetic brake connector

Connect to CN1

∗1

Input signals

Connect to CN5

External potentiometer or

External DC voltage

Input signal common (0 V)

Output signals

Connect to CN6

Grounding

Connection cable

∗2

Motor cable

Main power supply

Connect to TB1

Protective Earth Terminal

Be sure to ground.

Protective Earth Terminal

Be sure to ground.

Grounding

∗1

Electromagnetic brake type only

∗2

Check the USER MANUAL for details on the connection.

Connect in accordance with the polarities.

Note

•

Have the connector plugged in securely. Insecure connections may cause malfunction or damage to the motor or driver.

•

When connecting the 24 VDC power supply, check the indication of the driver case and pay attention to the polarity of the power

supply. Reverse-polarity connection may cause damage to the driver.

•

Do not wire the power supply cable of the driver in the same cable duct with other power lines or motor cables. Doing so may cause

malfunction due to noise.

•

When cycle the power or plugging/unplugging the connector, turn off the power and wait for the CHARGE LED to turn off before doing

so. Residual voltage may cause electric shock.

•

When installing the motor to a moving part, use an accessory flexible cable offering excellent flexibility. Refer to the USER MANUAL

for details.

Connecting the power supply (TB1)

Connect the power cable to the main power supply input terminals (TB1) on the driver.

Input power supply

Connecting method

Single-phase 100-120 V Connect the live side to terminal L, and the neutral side to terminal N.

Single-phase 200-240 V Connect the live side to terminal L1, and the neutral side to terminal L2.

Three-phase 200-240 V Connect the R, S and T phase lines to the L1, L2 and L3 terminals, respectively.

•

z

Power connection terminal and cable

Applicable crimp terminal: Round crimp terminal with insulation cover

Thread size of terminal: M3.5

Tightening torque: 1.0 N·m (8.8 lb-in)

Applicable lead wire: AWG18 to 14 (0.75 to 2.0 mm

2

)

Conductive material: Use only copper wire.

3.8 (0.15) or less

7.2 (0.28) or less

6.2 (0.24) or less

after crimping

Ø3.6 (0.14) or more

Unit: mm (in.)

Circuit breaker

Be sure to connect a circuit breaker to the power line of the driver to protect the primary circuit.

Rated current of protective device: Single-phase input 10 A, three-phase input 5 A

Circuit breaker: Mitsubishi Electric Corporation NF30