3

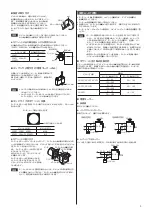

Attaching Load

To shaft of the gearhead has been machined to an outer diameter tolerance of

h7 and is provided with a key slot for connecting the transmission parts.

When connecting the transmission

parts, ensure that the shaft and parts

have a clearance fit, and always fix the

parallel key to the output shaft with a

screw to prevent the parts from rattling or

spinning.

Screw

Parallel key

Gearhead output shaft

Note

Do not use excessive force, or hammer the transmission parts onto

the gearmotor shaft as damage may occur.

z

z

When using the output axis tip screw hole of a gearhead

Use a screw hole provided at the tip of the output shaft as an auxiliary means for

preventing the transfer mechanism from disengaging.

(

2GV

,

3GV

type have no output shaft

tip screw hole.)

Screw

Spacer

Transmission

parts

Fixed screw

Gearhead model

Output shaft tip

screw hole

4GV

M5

5GV

,

5GVH

,

5GVR

M6

Mounting the capacitor (only for single-phase motors)

Before mounting the provided capacitor, check that

the capacitor's capacitance matches that stated on the

motor's name plate.

Mount the capacitor securely by using M4 screws

(not provided).

Ø4.3 mm

(0.169 in.)

Note

z

•

Do not let the screw fastening torque exceed 1 N·m (8.8 lb-in) to

prevent damage to the mounting foot.

z

•

Mount capacitor at least 10 cm (3.94 in.) away from the motor. If it

is located closer, the life of the capacitor will be shortened.

Changing gearhead of the combination type

Remove the gearhead by unscrewing the hexagonal socket-head screws holding

the gearhead to the motor (2 locations).

Hexagonal socket-head

screw (2 locations)

Illustration shows the view

from motor case side.

Gearhead model

Nominal

diameter of

screw

2GV

,

3GV

,

4GV

M2.6

5GV

,

5GVH

,

5GVR

M3

z

z

Installing the gearhead

Using the pilot sections of the motor and gearhead as guides, slowly rotate it

clockwise/counterclockwise to prevent the pinion of the motor output shaft from

contacting the side panel or gear of the

gearhead.

Also confirm that no gaps remain

between the motor and gearhead.

An O-ring is attached to the flange of

the 90 W type motor. Do not pinch the

O-ring when assembling the motor and

gearhead. Pinching the O-ring causes

a grease leak from the gearhead.

Output shaft of motor

Gearhead

Mating surface

Flange

Motor

Pilot section

Note

Do not forcibly assemble the motor and gearhead. Also, do not let

metal objects or other foreign matters enter the gearhead. The pinion

or gear of the motor output shaft may be damaged, resulting in noise

or shorter service life.

Connection and operation

Insulate all the wire connections, such as the connection between the motor and

the capacitor connection. Ground the motor using a Protective Earth Terminal.

The direction of motor rotation is as viewed from the side of the motor’s output

shaft. The motor rotates in a clockwise (CW) and counterclockwise (CCW)

direction.

Refer to the OPERATING MANUAL for the speed controller about the

connection of the motor and speed controller.

Note

z

•

Make sure that the motor case temperature does not exceed 90 °C

(194 °F) during operation of the motor.

Operation exceeding case temperature 90 °C (194 °F) may

significantly deteriorate the coils and ball bearings of the motor

and shorten the motor's life span. Motor case temperature can be

measured by fixing a thermometer on the motor surface. It can also

be measured using thermo tape or a thermocouple.

z

•

To change rotation direction of the induction motor, wait until the

motor completely stops. Otherwise its direction may not change or

may take much time to change.

z

•

Motors use a capacitor and keep it connected even after rotation of

the motor has started.

Rotating direction of the gearhead output shaft

The rotating direction of the gearhead output shaft may be opposite that of the

motor shaft, depending on the gear ratio. Before performing wiring, be sure

to check the rotating direction of the gearhead output shaft to be used and

determine the desired direction of motor rotation.

Gearhead model

Gear ratio

Same as the rotating

direction of motor shaft

Opposite the rotating

direction of motor shaft

2GV

,

3GV

,

4GV

5 to 25

30 to 120

150 to 360

5GV

,

5GVH

5 to 18

25 to 100

120 to 300

5GVR

5 to 15

18 to 60

75 to 180

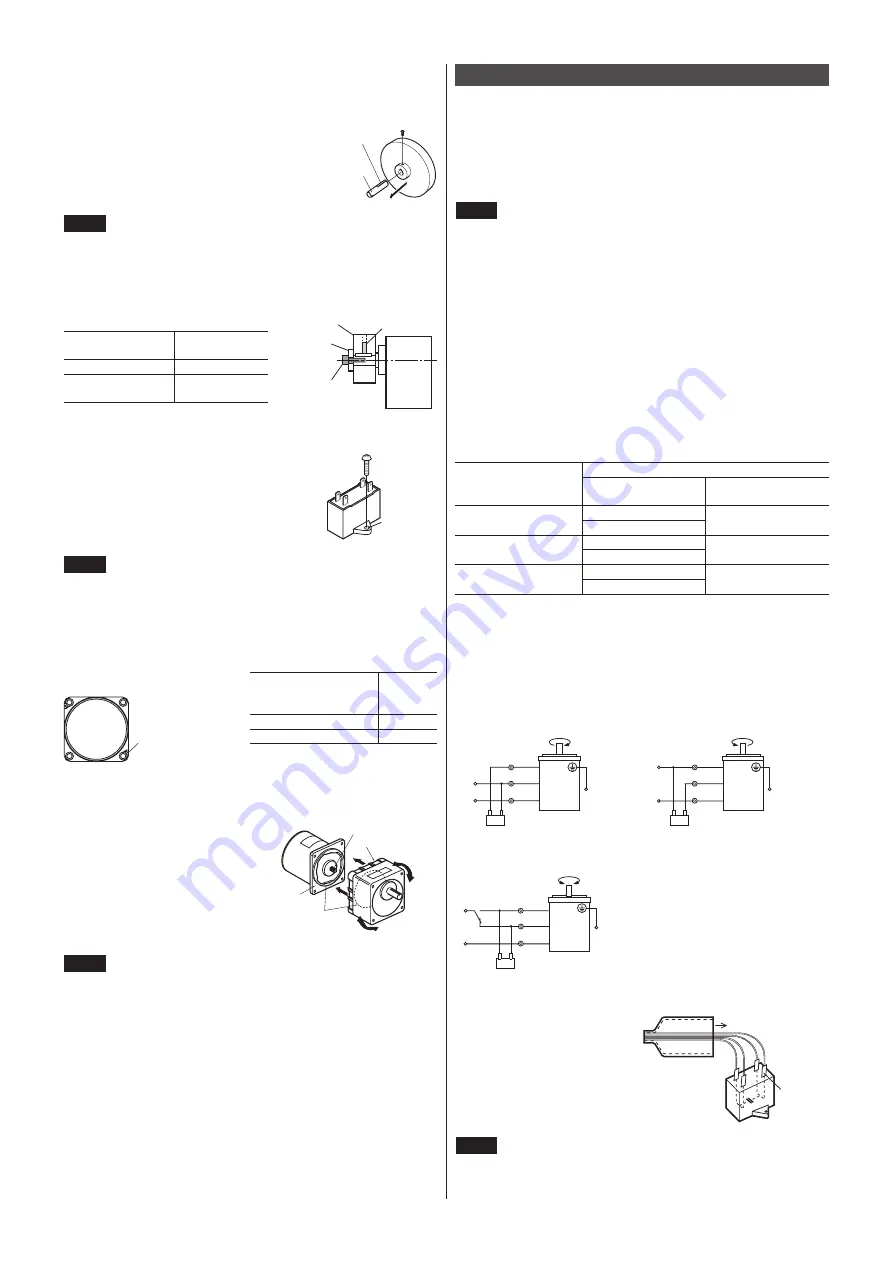

Single-phase motors

z

z

Wiring diagram

Connect the motor according to the figure.

Induction motors

The connection method will vary, depending on the direction.

Capacitor

Black

Red

L

N

White

Motor

PE

CW

<Clockwise>

White

Red

L

N

Black

Motor

PE

Capacitor

<Counterclockwise>

CCW

Reversible motors

CCW

Motor

CW

Black

White

CW

CCW

L

N

Red

PE

Capacitor

To rotate the motor in a clockwise (CW)

direction, flip switch to CW. To rotate it in

a counterclockwise (CCW) direction, flip

switch to CCW.

z

z

Capacitor connection (only for single-phase motors)

z

•

Use the supplied capacitor cap to insulate the capacitor terminal connection.

z

•

The capacitor internal wiring as

follows: Capacitor terminals are

internally electrically connection

in twos; A-B and C-D for easy

connection. For easy to install

terminals use 187 series FASTON

terminals (TE Connectivity).

187 series

tab

Capacitor

Capacitor cap

A

B

C

D

Note

For lead wire connection, use one lead wire for each individual

terminal.