4

z

•

Unauthorized reproduction or copying of all or part of this manual is

prohibited.

z

•

Oriental Motor shall not be liable whatsoever for any problems relating

to industrial property rights arising from use of any information, circuit,

equipment or device provided or referenced in this manual.

z

•

Characteristics, specifications and dimensions are subject to change without

notice.

z

•

While we make every effort to offer accurate information in the manual, we

welcome your input. Should you find unclear descriptions, errors or omissions,

please contact the nearest office.

z

•

is a registered trademark or trademark of Oriental Motor Co.,

Ltd., in Japan and other countries.

© Copyright ORIENTAL MOTOR CO., LTD. 2012

Published in November 2017

Technical Support Tel:(800)468-3982

8:30

A.M.

to 5:00

P.M.

, P.S.T. (M-F)

7:30

A.M.

to 5:00

P.M.

, C.S.T. (M-F)

www.orientalmotor.com

Schiessstraße 44, 40549 Düsseldorf, Germany

Technical Support Tel:00 800/22 55 66 22

www.orientalmotor.de

Tel:01256-347090

www.oriental-motor.co.uk

Tel:01 47 86 97 50

www.orientalmotor.fr

Tel:02-93906346

www.orientalmotor.it

Tel:+55-11-3266-6018

www.orientalmotor.com.br

• Please contact your nearest Oriental Motor office for further information.

4-8-1Higashiueno,Taito-ku,Tokyo 110-8536

Japan

Tel:03-6744-0361

www.orientalmotor.co.jp

Tel:0800-060708

www.orientalmotor.com.tw

Singapore

Tel:1800-8420280

www.orientalmotor.com.sg

Tel:1800-806161

www.orientalmotor.com.my

Korea

Tel:080-777-2042

www.inaom.co.kr

Tel:1800-888-881

www.orientalmotor.co.th

Tel:400-820-6516

www.orientalmotor.com.cn

Tel:+91-80-41125586

www.orientalmotor.co.in

Hong Kong Branch

Tel:+852-2427-9800

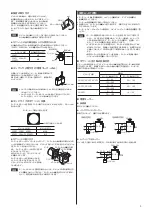

Three-phase motors

Connect the motor according to the

figure. When connected according to the

connection diagram, the motor will

operate in the clockwise direction (CW) as

viewed from the motor’s output shaft.

To change the direction of rotation,change

any two connections between R, S and T.

Red

White

L1(R)

L2(S)

L3(T)

Black

Motor

PE

CW

Connecting Protective Earth Terminal

Ground the motor using the motors with a Protective Earth Terminal .

Applicable crimp terminal:

Insulated round crimp terminal

Terminal screw size: M4

Tightening torque:

1.0 to 1.3 N·m (8.8 to 11.5 lb-in)

Applicable minimum lead wire size:

AWG18 (0.75 mm

2

) or more

Unit [mm (in.)]

Ø4.1 (0.16) min.

4.8 (0.19) max.

9.5 (0.37) max.

Note

Do not use screws other than the Protective Earth Terminal screws

attached on the product.

Time rating

Note

The continuous-operation time when operating the motors with the

speed controllers depends on the load, set speed and operating

cycle.

z

z

Induction motors

Induction motors have a continuous rating.

z

z

Reversible motors

Reversible motors have a 30 minutes rating. “30 min” is indicated on the

nameplate.

Locked rotor burnout protection

This motor is equipped with one of the two features listed below to prevent the

motor from burning out as a result of abnormal heating which may be caused by

misapplication.

Thermal protection

“TP” is stamped on the motor nameplate. The motor has an “auto reset”

type thermal protector built into its motor coil. When the motor reaches a

predetermined temperature, the internal thermal protector is activated and the

motor is stopped.

Always turn the power off before performing inspections.

Thermal protector activation range:

Power is turned off at 130±5 °C (266±9 °F)

Power is turned back on at 85±20 °C (185±36 °F)

Impedance protection

“ZP” is stamped on the motor nameplate. The motor has higher coil impedance.

When the motor goes into locked rotor condition due to a malfunction, coil

impedance rises, suppressing input power to the motor and protecting the motor

coil from burnout.

Troubleshooting

When the motor cannot be operated correctly, refer to the contents provided in

this section and take appropriate action. Refer also to the OPERATING MANUAL

for the speed controller. If the problem persists, contact your nearest office.

Phenomena

Check items

Motor does not rotate.

z

•

Check the power supply voltage.

z

•

Connect the power supply and the motor correctly.

z

•

Speed control motors connect correctly by

referring to the OPERATING MANUAL for the

speed controller.

z

•

With a single-phase motor, connect the supplied

capacitor correctly.

z

•

If terminal blocks or crimp terminals are used,

check them for poor connection.

z

•

Keep the load at or below the allowable value.

Phenomena

Check items

Motor sometimes rotates

and stops.

z

•

Connect the power supply and the motor correctly.

z

•

Speed control motors connect correctly by

referring to the OPERATING MANUAL for the

speed controller.

z

•

With a single-phase motor, connect the supplied

capacitor correctly.

z

•

If terminal blocks or crimp terminals are used,

check them for poor connection.

The motor rotates in the

direction opposite to the

specified direction.

z

•

Speed control motors connect correctly by

referring to the OPERATING MANUAL for the

speed controller.

z

•

With a single-phase motor, connect the supplied

capacitor correctly.

z

•

The rotating direction of the motor output shaft

may be different from that of the gearhead output

shaft depending on the gear ratio of the gearhead.

See "Rotating direction of the gearhead output

z

•

The rotating direction is indicated as viewed

from the motor output shaft. Check the reference

direction.

Motor temperature

abnormally high

[Motor case temperature

exceeds 90 °C (194 °F)]

z

•

Check the power supply voltage.

z

•

With a single-phase motor, connect the supplied

capacitor correctly.

z

•

Review the ventilation condition.

Noisy operation

z

•

Assemble the motor and gearhead correctly by

referring to the OPERATING MANUAL for the

gearhead.

z

•

Assemble a gearhead of the same pinion type as

the motor.