Installation

−8−

Maximum rotational torque (moment)

Keep the rotational torque received by the rack to or below the permissible value, as applicable, specified in

the table below.

Linear head model

Permissible rotational torque (moment) on rack

2LS

type

0.3 N·m (2.6 lb-in) or less

4LS

type

0.5 N·m (4.4 lb-in) or less

Note

If the rack receives excessive rotational torque, the rack bushing will wear quickly.

Gap between rack and rack bushing

There is a slight gap between the rack and rack bushing of the linear head. Initial values of the backlash

generated from the gap would be as follows.

A

B

D

C

Backlash generated from gap

•

A, B directions: About 2 mm

•

C direction: About 0.5 mm

•

D direction: About 0.5°

*

The above gap dimensions in directions A and B are measured at

500 mm (19.69 in.) from the end face of the case on the linear head.

As the rack is operated repeatedly, the rack bushing will wear, and also this backlash will increase.

If you have concerns about the backlash, install a guide and others.

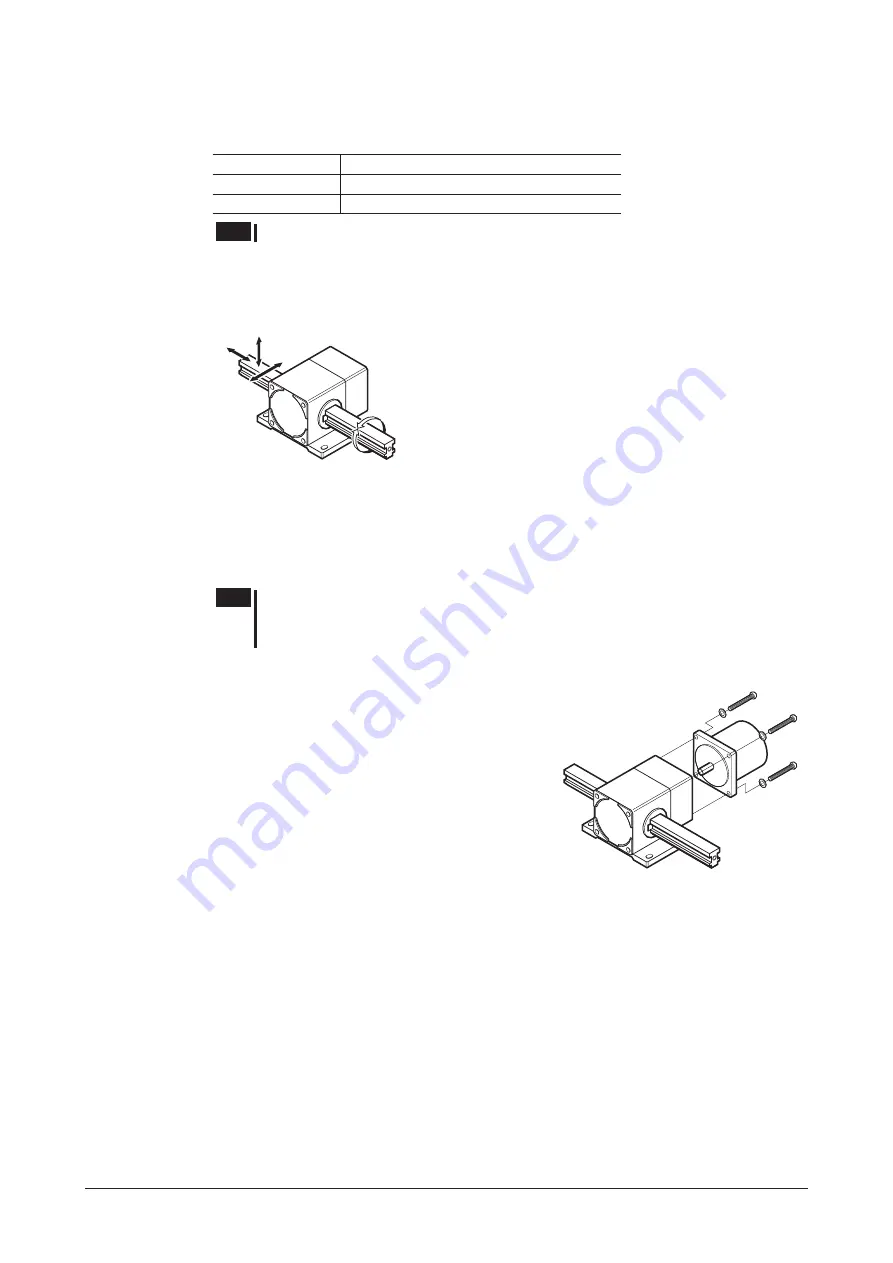

3.4 Assembling the motor

The assembly method varies between the

2LS

type and

4LS

type.

Note

•

When assembling the motor, do not damage the motor shaft and gear. Noise will occur.

•

In the case of a motor of the terminal box type, assemble the motor in a manner

preventing the terminal box from contacting the limit switch.

2LS

Type

1.

Affix the gear case and rack case using an adhesive

tape, etc., so that the two will not separate from each

other.

2.

Remove the screws and washers assembling the

gear case and rack case.

3.

Assemble the motor, and affix the motor, gear

case and rack case using the screws and washers

removed in the preceding step.

Tightening torque: 1.8 N·m (250 oz-in)

4LS

Type

Affix the motor to the gear case using the supplied screws.

Tightening torque: 3.8 N·m (530 oz-in)