Installation

−7−

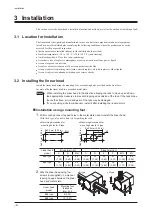

Installation using mounting holes on the front face

1.

Drill mounting holes or tapped holes in the metal plate used to install the linear head.

The same machining dimensions for mounting holes apply to both the B type and F type.

J±0.5 mm (0.02 in.)

J±0.5 mm (0.02 in.)

Linear head model

J [mm (in.)]

2LS

type

47 (1.85)

4LS

type

62 (2.44)

2.

Affix the linear head using four screws (not supplied) in a manner leaving no gaps between the

linear head and metal plate.

L

Linear head model

L

2LS

type

M6 Effective depth

10 mm (0.39 in.)

4LS

type

M8 Effective depth

10 mm (0.39 in.)

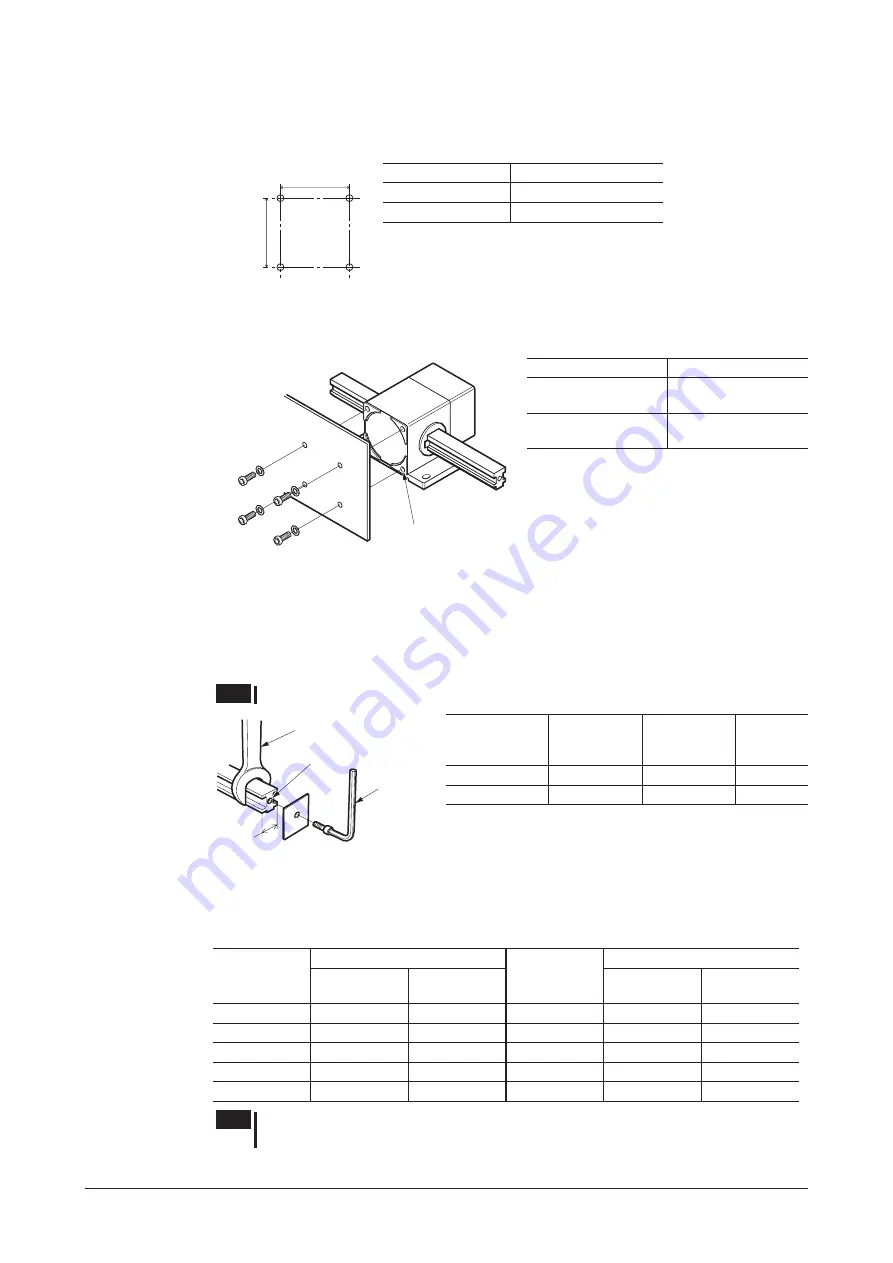

3.3 Installing a load

Install the load using hexagonal socket head bolts (not supplied) through the tapped holes provided on the end

face of the rack.

When installing the load, always secure the rack with a wrench so that the rack will not receive rotational

force while the load is affixed.

Note

When installing the load, align the axial centerline of the rack with that of the load.

Wrench

Tapped hole

A

Hex wrench

Linear head

model

Thread size

Effective

depth

[mm (in.)]

Dimension

A

[mm (in.)]

2LS

type

M5

10 (0.39)

16 (0.63)

4LS

type

M8

15 (0.59)

20 (0.79)

Maximum radial load

Keep the radial load received by the rack end to or below the permissible value, as applicable, specified in the

table below.

Stroke

[mm (in.)]

Linear head model

Stroke

[mm (in.)]

Linear head model

2LS

type

[N (lb.)]

4LS

type

[N (lb.)]

2LS

type

[N (lb.)]

4LS

type

[N (lb.)]

100 (3.94)

55 (12.3)

120 (27)

600 (23.62)

15 (3.3)

40 (9)

200 (7.87)

40 (9)

90 (20)

700 (27.56)

12 (2.7)

40 (9)

300 (11.81)

30 (6.7)

70 (15.7)

800 (31.50)

8 (1.8)

25 (5.6)

400 (15.75)

25 (5.6)

60 (13.5)

900 (35.43)

─

20 (4.5)

500 (19.69)

20 (4.5)

50 (11.2)

1000 (39.37)

─

15 (3.3)

Note

Even if the radial load does not exceed the permissible value, it is recommended to still

install a guide, etc., to reduce or disperse the radial load.