6

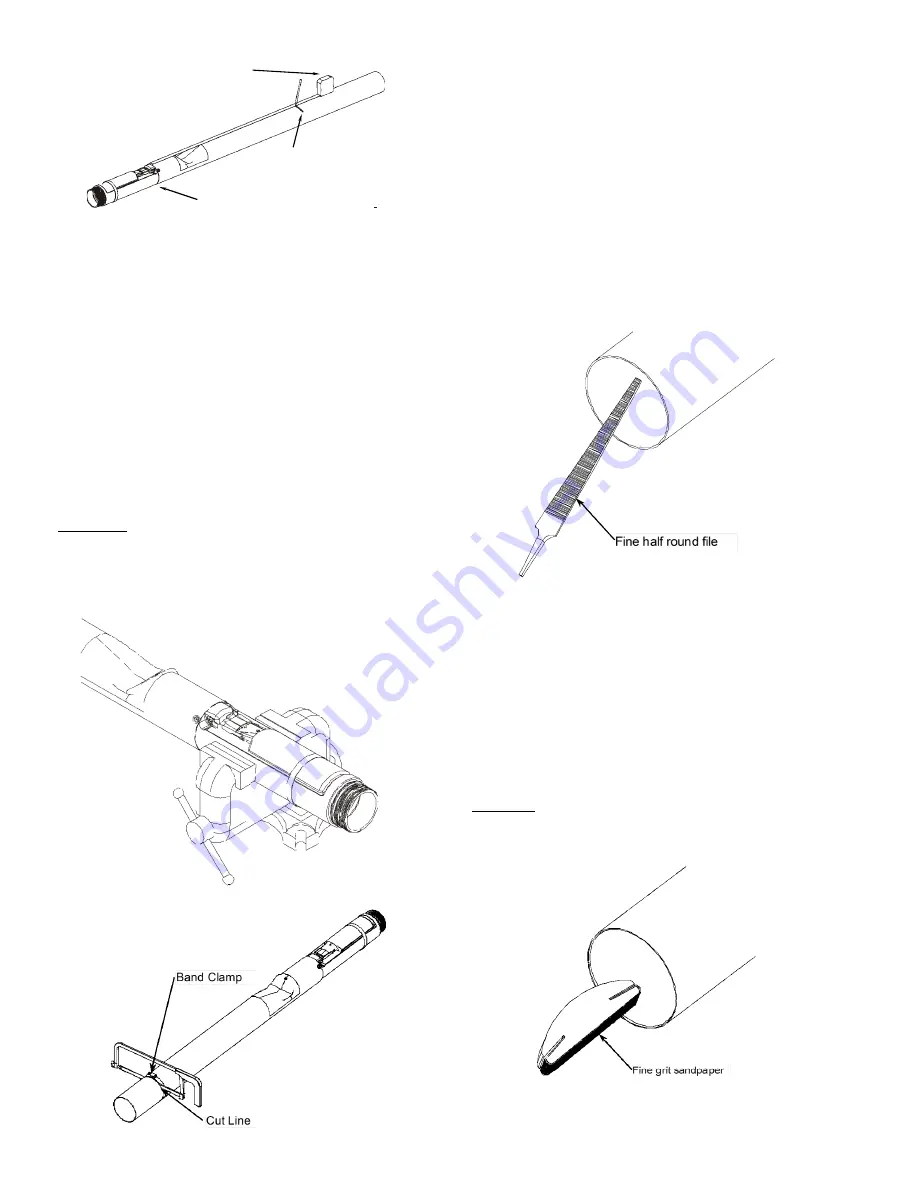

STEP 3: CUT THE UPPER DROP TUBE

Attach the supplied band clamp to the upper tube just

below the mark and ensure that it is assembled square

to the tube. The clamp can be used as a guide for mak-

ing a square cut. If a vise is used, clamp on the valve

body casting only to avoid damage to the float and

tubes

(See Figure 3A).

Carefully saw through the tube

squarely, at the mark made in Step 2. Use a hacksaw

with a new fine-tooth blade. Rotating the upper tube

as the sawing progresses will minimize run out and en-

sure a square 90-degree cut. Remove the band clamp

after tube is cut.

CAUTION - DO NOT use a pipe or tubing cutter to cut

the upper drop tube, this may damage the tube,

causing it to be out of round thereby prohibiting

assembly of the unit.

IMPORTANT:

Remove all chips and shavings generated

in steps 3 thru 5 out of the cut end of the tube. DO NOT

remove chips and shavings by dumping thru valve

body.

STEP 4: FILE THE UPPER DROP TUBE

File the upper tube square, and remove any burrs or

rough edges. Make sure the cut is flat and square.

IMPORTANT:

Carefully file a good chamfer on the in-

side edge of the drop tube to provide a lead-in for the

polypak seal and inlet tube installed in Step 8.

Figure 4

STEP 5: SAND THE UPPER DROP TUBE

Sand the inside of the drop tube with sandpaper and/or

steel wool to remove all burrs and sharp edges. After

sanding wipe down the inside of the tube with a clean

rag from the top to approximately 4 inches down to

remove any debris.

Caution: Failure to properly chamfer, sand, and

clean the drop tube may cut the seal and result in a

failure of a pressure decay leak test.

Figure 5

Seam

Tape measure

Mark Upper Tube

(Cut Line)

Figure 2

Figure 3A

Figure 3B