Cod. 710.0138.01.00 Rev04A

– 03.2017

© Copyright 2017 OMI Srl - All rights reserved

10

– 12

TROUBLE

DISPLAY

POSSIBLE CAUSE

REMEDY

LOW PRESSU

RE IN T

HE LI

NE

Ice formation in the evaporator.

Check the probe; if the trouble persists, replace it.

Check the electronic control board; if the trouble persists,

replace it.

Contact our Service Centre to check the gas charge.

Clog.

Check if the compressed air inlet/outlet is connected properly.

Check if the connecting tubing is clogged; in case proceed

accordingly.

Check if any valves are closed.

Check the condition of any filter.

Air flows continuously through the

condensate drainage.

Drainage solenoid valve jammed, clean or replace it.

Verify the condensate drainage times set on the electronic control

board (C8 and C9).

Check the signal from the control board: if it is continuous,

replace the control board.

Check the no loss condensate drain; if the trouble persists,

replace it.

IMPORTANT

:

The temperature control probe is extremely delicate. Do not remove the probe from its position. In case of any kind of

problem, please contact your localOMI distributor

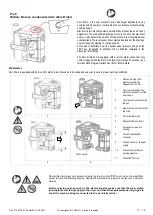

Pic.3 drain solenoid valve

When it is necessary:

Clean the mesh filter of the

condensate drainage system.

Clean the filter mesh.

Pic.4

Optional: No loss condensate drain (Beko)

Electronic drain discharge Beko is the new discharger applicable to any

compressed air systems. It eliminates the condensate without wasting

compressed air.

Electronic drain discharge starts automatically, without the need of any

adjustment. The condensate discharge occurs to the use of an electronic sensor,

which detects the amount of condensate in the integrated water collecting tank.

The level sensor drives start and duration of the drainage, so preventing any

wasting of compressed air.

At the end of installation, put the system under pressure and push the TEST key

repeatedly to eliminate the air bubbles contained in the discharger inlet fittings.

Please refer to the attached CD of the discharger for complete instructions.

To this discharger will be applied the Beko warranty conditions.

Filter mesh

Cleaning of the drain solenoid valve

Содержание ED18

Страница 2: ......

Страница 4: ...Cod 710 0138 01 00 Rev04A 03 2017 Copyright 2017 OMI Srl All rights reserved...