31

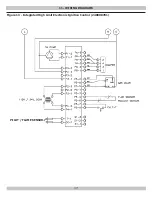

APPENDIX A - CONTROL MODULE

— If flame rod or bracket is bent out of position, restore

to correct position.

STEP 3:

Check spark ignition circuit.

Disconnect ignition cable at SPARK terminal on module.

WARNING

Electrical shock hazard. Ignition circuit generates

over 10,000 volts. Turn OFF electrical power

supply at service panel before making electrical

connections. Failure to do so could result in death

or serious injury.

!

Energize module and listen for audible sparking noise.

When operating normally, there should be buzzing noise

turns on and off twice per second for duration of 1–7

seconds, depending on model.

STEP 4:

Verify pilot and main burner light-off.

• Initiate call for heat. Turn thermostat above room

temperature. Ignition sequence may be delayed by

thermal purge until boiler water temperature is below

140°F (60°C)

• Watch pilot burner during ignition sequence.

— Verify ignition spark continues after pilot is lit.

— Verify pilot lights and spark stops, verify main

burner does not light.

•

If so, ensure adequate flame current as follows.

— Turn off boiler at circuit breaker or fuse box.

— Clean flame rod with emery cloth.

— Verify electrical connections are clean and tight.

Replace damaged wire..

— Check for cracked ceramic insulator, which can

cause short to ground, and replace igniter-sensor if

necessary.

— At gas valve, disconnect main valve wire from MV

terminal.

— Turn on power and set thermostat to call for heat. Pilot

should light, main burner will remain off because main

valve actuator is disconnected.

— Check pilot flame. Verify it is blue, steady and

envelops 3/8 to 1/2 in. [10 to 13 mm] of flame rod.

See Figure 19 for possible flame problems and causes.

— If necessary, adjust pilot flame by turning pilot

adjustment screw on gas control clockwise to decrease

or counterclockwise to increase pilot flame. Following

adjustment, always replace pilot adjustment cover

screw and tighten firmly to assure proper gas control

operation. Figure 16, page 20.

— Set temperature below room set-point to end call for

heat.

• Recheck ignition sequence as follows.

— Reconnect main valve wire.

— Adjust thermostat above room temperature.

— Verify ignition sequence at burner.

— If spark does not stop after pilot lights, replace

module.

— If main burner does not light or if main burner lights

and system locks out, check module, ground wire and

gas control as described in troubleshooting table. See

Table 7, Page 30.

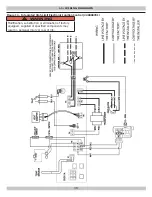

Figure 19 - Troubleshooting Pilot Flame

Correct Pilot Flame: 3/8 to 1/2 inch in flame.

See Figure 16, Page 21.