CHAPTER 3 MAINTENANCE PROCEDURES

Valor

™

7000 Series Service Manual

3-5

Ohaus Corporation www.ohaus.com

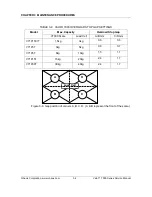

TABLE 3-1. MOUNTING BOLT TORQUE SETTINGS

MODEL

TORQUE SETTING

V71P1501T

6N to 8N

V71P3T

6N to 8N

V71P6T

6N to 8N

V71P15T

6N to 8N

V71P30T

6N to 8N

6. Set Overload Stops as shown in Section 3.6.

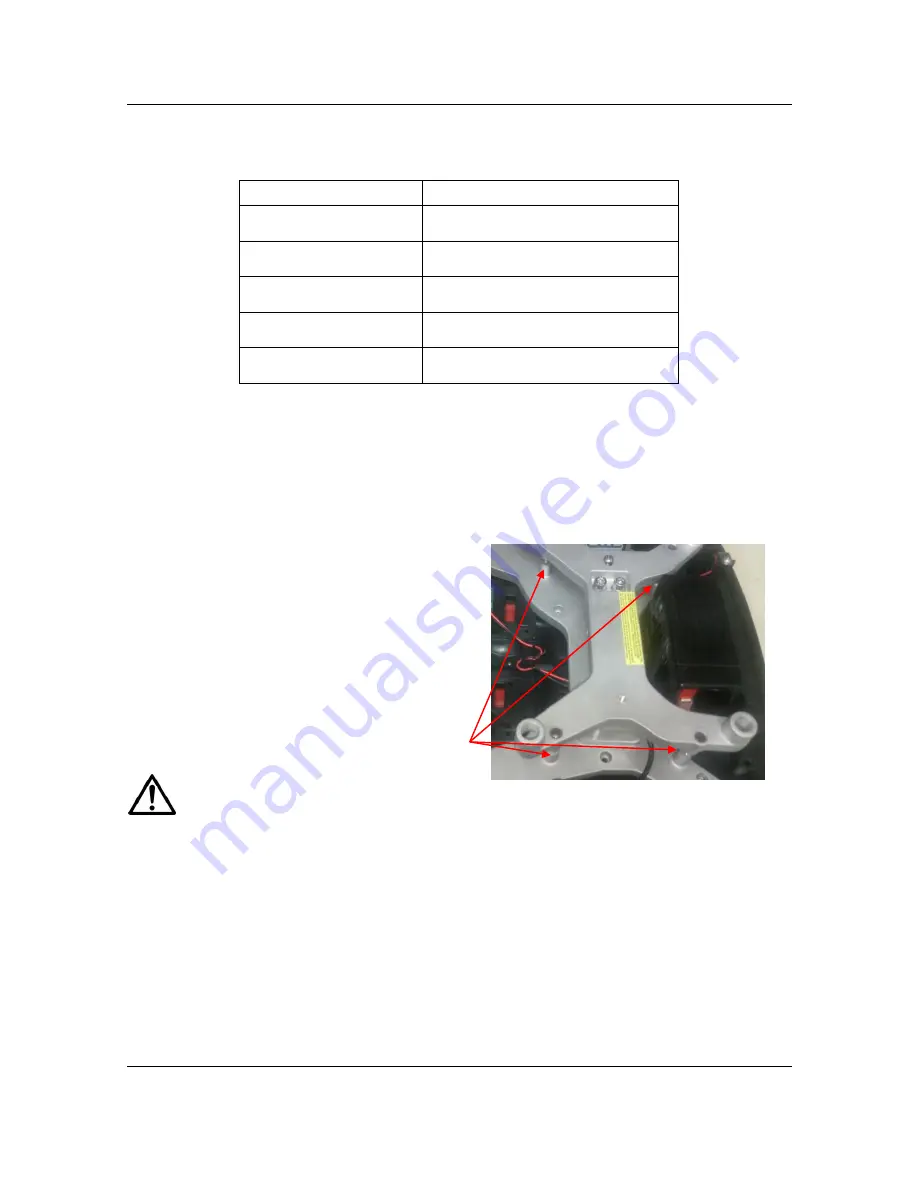

3.6 Setting the Overload Stops

The Overload Stop gaps must be checked and reset if the Load Cell is replaced. This

procedure requires test masses equal to the scale

’s capacity. (

See Table 3-2.)

There are four Overload Stop Bolts. (See Figure 3-5.)

Adjust the Overload Stops, per Table 3-2:

1. Adjust the Overload Stop Bolt so that

the gap between the Load Cell Frame

and the Overload Stop Nut is equal to

the specification in Table 3-2. (The

gap can be tested by applying 100%

load, one corner at a time, at each

corner stop. If the gap is right, the Load

Cell Frame will just touch the Overload

Stop Nut.)

Note:

Be careful not to overload the

Load Cell, which would damage it.

2. Repeat this for all four corners.

3. Test the scale to see if full capacity

can be achieved.

Figure 3-5. Overload Stops.

Overload

Stops