15

7.

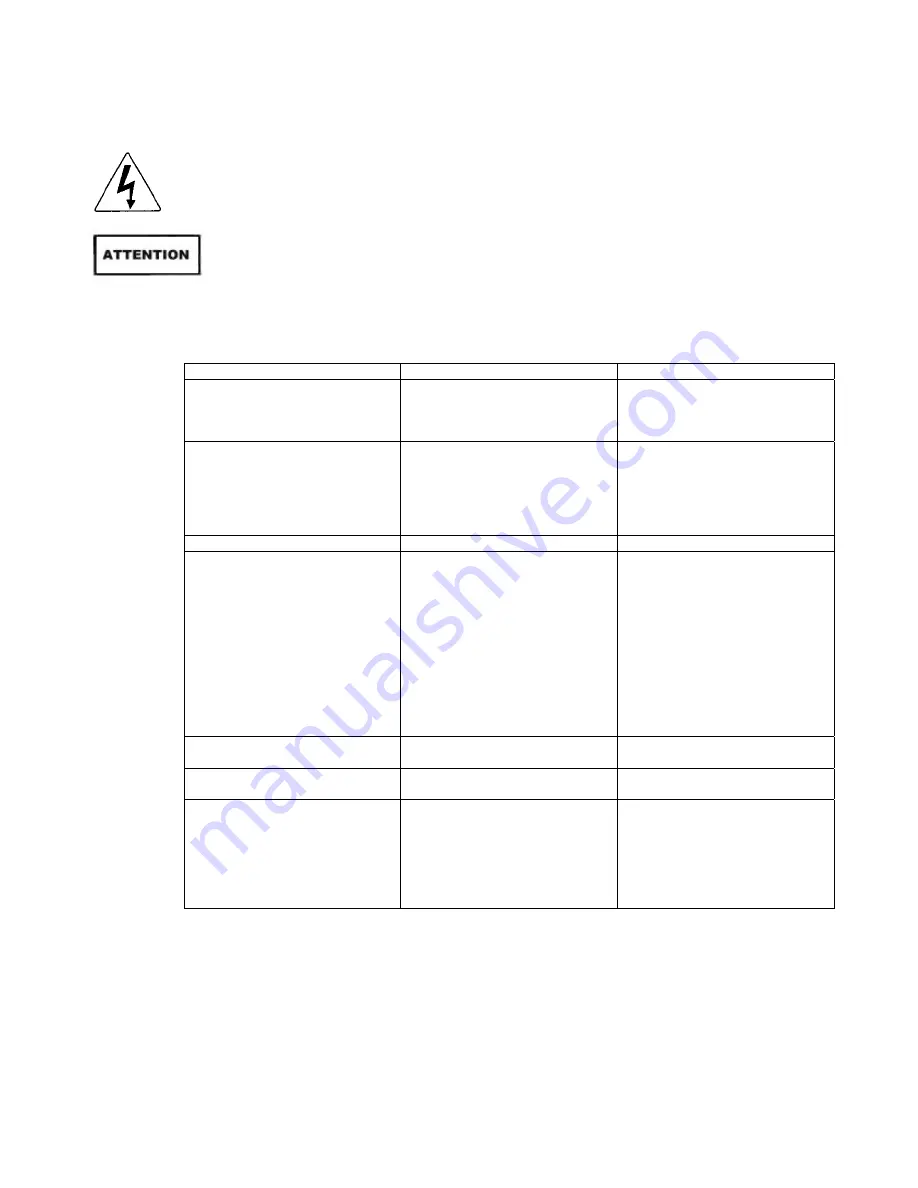

Trouble Shooting

Electrical energy can cause severe injuries. Devective electrical

components to be immediately replaced, possible causes for accidents

to be eliminated without delay

Any repair work must only be carried out by qualified personnel.

Only original OERTZEN equipment to be installed, as otherwise

warranty and Declaration of Conformity will be void, health and

safety standards are not guaranteed.

During repair or maintenance work, unit to be disconnected from

electrical network.

Faiure Cause

Remedy

Motor stops

- Fuel tank empty

- Motor oil low level

- Petrol filter blocked

- Sparking plug burnt

- Fill tank

- Fill up oil up to max. mark

- Clean/replace filter

- Replace sparking plug

Motor springt nicht an

- Motor oil low level.

- Counter pressure high

- Battery exhaused

- Ignition switch in position "Off"

- Petrol cock closed

- Choke open

- Fill up oil up to max. mark.

- Release unloader valve

- Charge battery

- Put switch into position "On"

- Open petrol cock

- Close choke

Pump pressure high

- Nozzle clogged

- Clean remove and nozzle

Operating pressure not achived/

varies

- Air in unit

- Insufficient water supply

- Nozzle worn

- Incorrect nozzle

- Nozzle clogged

- Water strainer blocked

- Unloader valve leaking

- Suction side of pump leaking

- Suction valves sticking

- Vent unit

- Supply line to be min.

”

- Replace nozzle

- Install correct nozzle

- Remove/clean nozzle

- Clean filter

- Call service

- Tighten hose clamps

- Carefully loosen valves by

means of a scew driver, if

needed, remove and clean

valves.

Vibrations on high pressure hose

and spray pistol

- Air in unit

- Open handle on pistol unless

continuous pressure is achieved

Heavy vibrations on unit

- Plunger blocked

- Stop unit immediately,

call service

No detergent injection

- Detergent tank empty

- Dosing valve or regulating

handle closed

- Low pressure nozzel in double

lance blocked

- Non-return valve blocked

- Fill tank

- Open

- Remove and clean nozzle

- Blow compressed air into

detergent hose

Содержание M 240

Страница 16: ...16 ...