26

300-

µµµµ

m Diameter Solarization-resistant Optical Fiber

The 300-µm Diameter Solarization-resistant Optical Fiber that comes with your CHEM2000-UV-VIS is a

single-strand optical fiber. The active part of our solarization-resistant fibers consists of a silica core,

surrounded by a silica cladding material. The fiber is then coated in aluminum. Our standard laboratory

cabling is blue PVC. Our solarization-resistant fibers are best used for applications where exposure to long-

term UV light occurs.

Solarization is the loss of transparency in glass due to exposure to ultraviolet radiation. If you are using a

UV light source, the UV radiation degrades the silica in a standard patch cord fiber over time, resulting in

increased overall absorption values and invalid data. This degradation is called solarization, which is the

formation of “color centers” or silica molecules with an unbound pair of electrons. These color centers have

an absorption band that is centered at 215 nm. In regular HOH fibers (our standard fibers), the

concentration of these color centers grows until nearly all UV light in the 215 nm region is blocked.

Other solarization-resistant fibers are hydrogen-loaded but their solarization-resistant properties do not

last as the hydrogen eventually leaks out of the silica -- meaning that these hydrogen-doped solarization-

resistant fibers have a “shelf life.” With Ocean Optics solarization-resistant optical fibers, there is no

shelf life.

Care and Use Guidelines

!

!

!

!

When fibers break, they stop transmitting light. Inspect fibers by eye to determine if light is being

transmitted.

!

!

!

!

Bending the fiber will cause attenuation. To minimize this effect, add extra strain relief to both ends

of the fiber.

!

!

!

!

Do not exceed the temperature specifications for the materials involved: 200

0

C for the fiber, 100

0

C

for PVC cabling, 100

0

C for standard epoxy.

!

!

!

!

Do not allow the fiber to be bent at a sharp angle. A bending radius of less than 1

"

is dangerous.

!

!

!

!

Keep connectors and probe tips covered when the fibers are not being used.

!

!

!

!

Clean the ends of the fibers with lens paper and distilled water, alcohol or acetone. Avoid scratching

the surface.

!

!

!

!

Do not immerse fiber ends in caustic materials or other solutions that can damage glass.

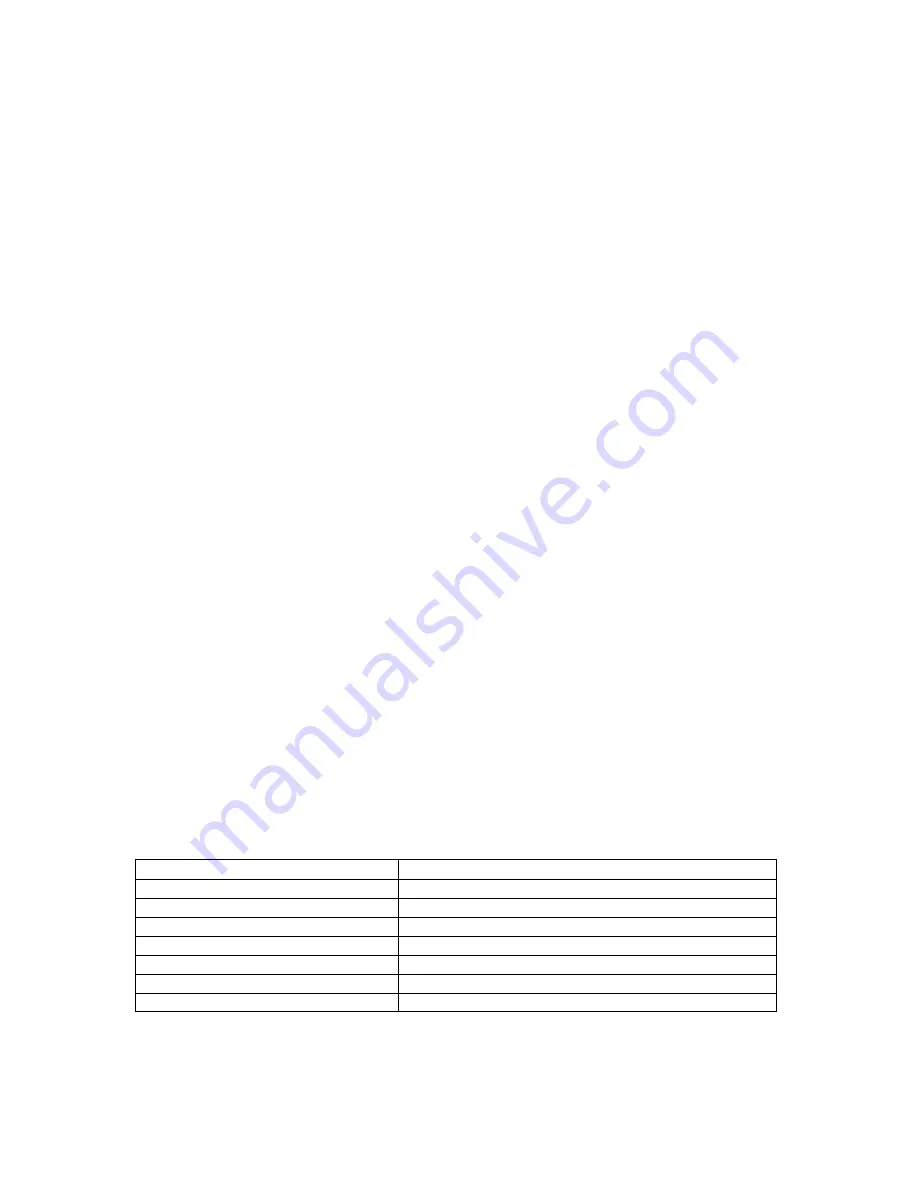

Specifications

Jacket:

Nylon (temperature range -40 to 100

°

C)

Sheathing/cabling:

PVC (standard)

Connector/termination:

SMA 905

Fiber core:

pure fused silica

Cladding:

doped fused silica

Fiber profile:

step-index multi-mode

Numerical aperture:

0.22

Recommended minimum bend radius:

momentary = 8 cm, long term = 16 cm