Voyager IV

Nitrox System

Nuvair www.nuvair.com

Page

30

Use only the specified Nuvair Lubricants in this system. The use of incompatible lubricants

presents a risk of fire and/or explosion, and may result in system damage. This can lead to

severe personal injury and death.

17.3 Compressor Lubricant

•

The LP Compressor in your Nitrox System comes standard with Nuvair 546 Synthetic

Food Grade Compressor Lubricant for Rotary Screw Compressors.

•

The HP Compressor comes with the Nuvair 455 Synthetic Food Grade Lubricant.

Check lubricant levels at each Sight Gauge and add lubricant as required through the

appropriate Fill Plug. Lubricant is removed through the Drain Plugs. See LP and HP

Compressor manuals for details on servicing Lubricant.

Never mix lubricants, they are different.

-Do not carry out these tasks if the compressor has only just shut down; wait for the

compressor to cool.

-Pressure must be drained before opening LP Fill Plug.

-Any oil spilt during the oil/filter change could cause personnel to slip; wear protective

garments and anti-slip footwear and remove traces of oil immediately.

-Both oil and filters are classified as special wastes and must therefore be disposed of in

compliance with the anti-pollution laws in force.

-Filter changes and oil filling must be done with the compressors OFF.

*Oil in the LP compressor should only be changed after the unit has been allowed to sit and cool for

several hours, allowing all oil to drain from the cooler in to the compressor sump.

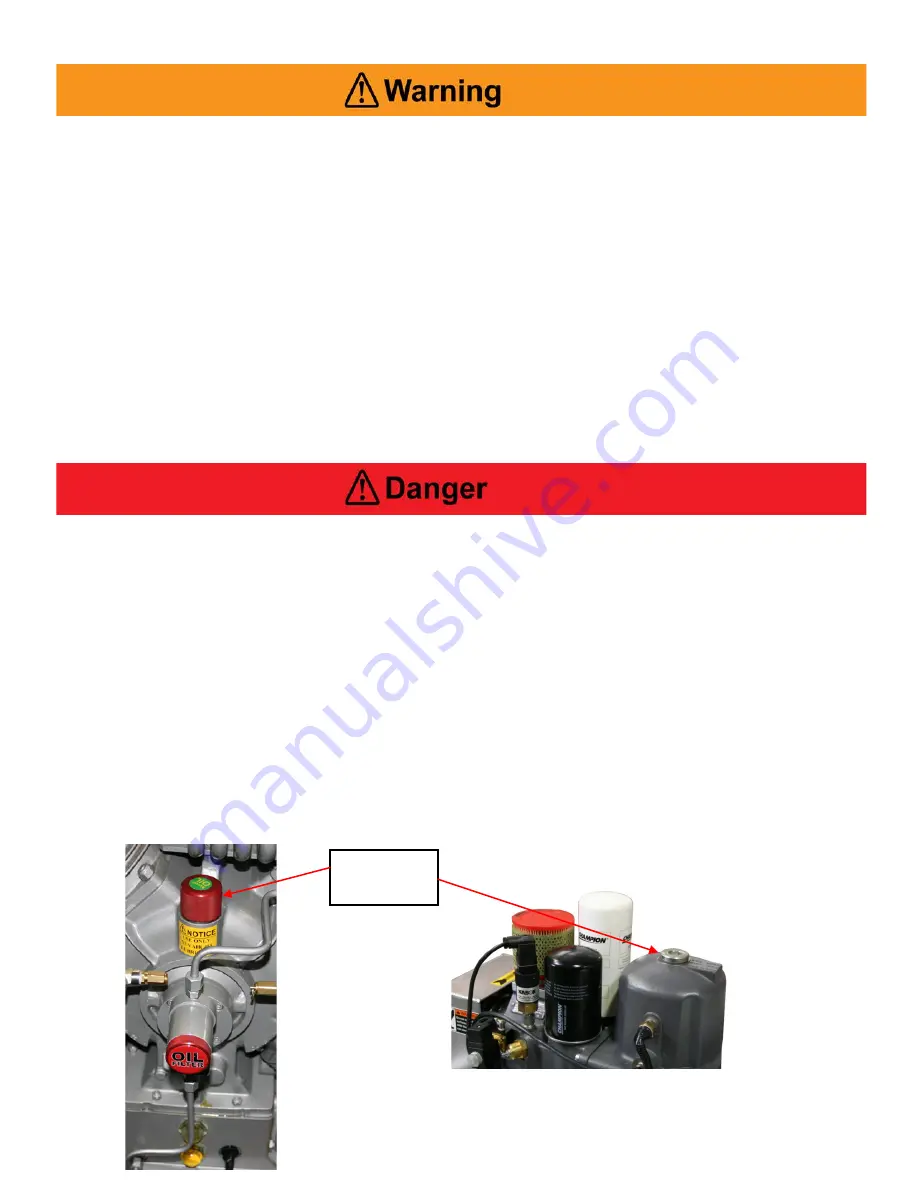

*When filling the LP compressor with oil:

1. Fill the sump until the oil level reaches the top of the sight tube

2. Follow the procedure for the daily oil level check, turning the compressor on and off

3. Continue filling as necessary to reach the appropriate oil level

Lubricant

Fill Plugs

Содержание Voyager IV

Страница 1: ...User and Maintenance Manual Voyager IV Nitrox System Rev 12 18 ...

Страница 39: ......