Page 2

04/21/20

Champion

®

RC300

FUNCTIONAL DESCRIPTION

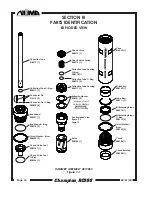

1. BACKHEAD

The backhead connects the hammer to the drill rod. Backheads can be manufactured

to be compatible with several reverse circulation drill rod designs. Please contact your

distributor or regional salesperson for more information. Wrench flats are provided for

disassembly.

2. CONNECTOR PINS

The connector pins are located on the top of the backhead, in the wirth flange. These

pins allow air to flow into the hammer via the adaptor/drill rod.

3. CHECK VALVE SEAT

The check valve seat provides the sealing surface for the check valve and guides the

collection tube.

4. CHECK VALVE

The check valve maintains pressure in the hammer when the air supply has been

shut off. The check valve in the hammer balances the hydrostatic pressure in the hole

thereby preventing contaminants from entering the hammer.

5. CHECK VALVE SPRING

The check valve spring provides tension under the check valve to keep it closed. It is

compressed as the air is turned on.

6. COLLECTION TUBE

The collection tube extends from the backhead to the bit and transfers the collected

drill cuttings to the inner drill pipe of the reverse circulation drill rod. The collection tube

is designed to be easily replaced without removing the backhead from the drill.

7. COLLECTION TUBE HOUSING

The collection tube housing aligns the collection tube. Holes in the collection tube

housing provide the necessary porting supply air.

8. BELLEVILLE WASHERS

Two belleville washers sit between the collection tube housing and the feed tube

housing to keep the feed tube housing tight against the shoulder in the hammer.

Содержание Champion RC300

Страница 2: ......

Страница 26: ...Page 22 04 21 20 Champion RC300 NOTES...

Страница 27: ...04 21 20 Page 23 Champion RC300 NOTES...