6

22. 02. 22. Document Number 611280

Nuaire | Western Industrial Estate | Caerphilly | CF83 1NA | nuaire.co.uk

DAVE Extract (DE)

Installation Manual

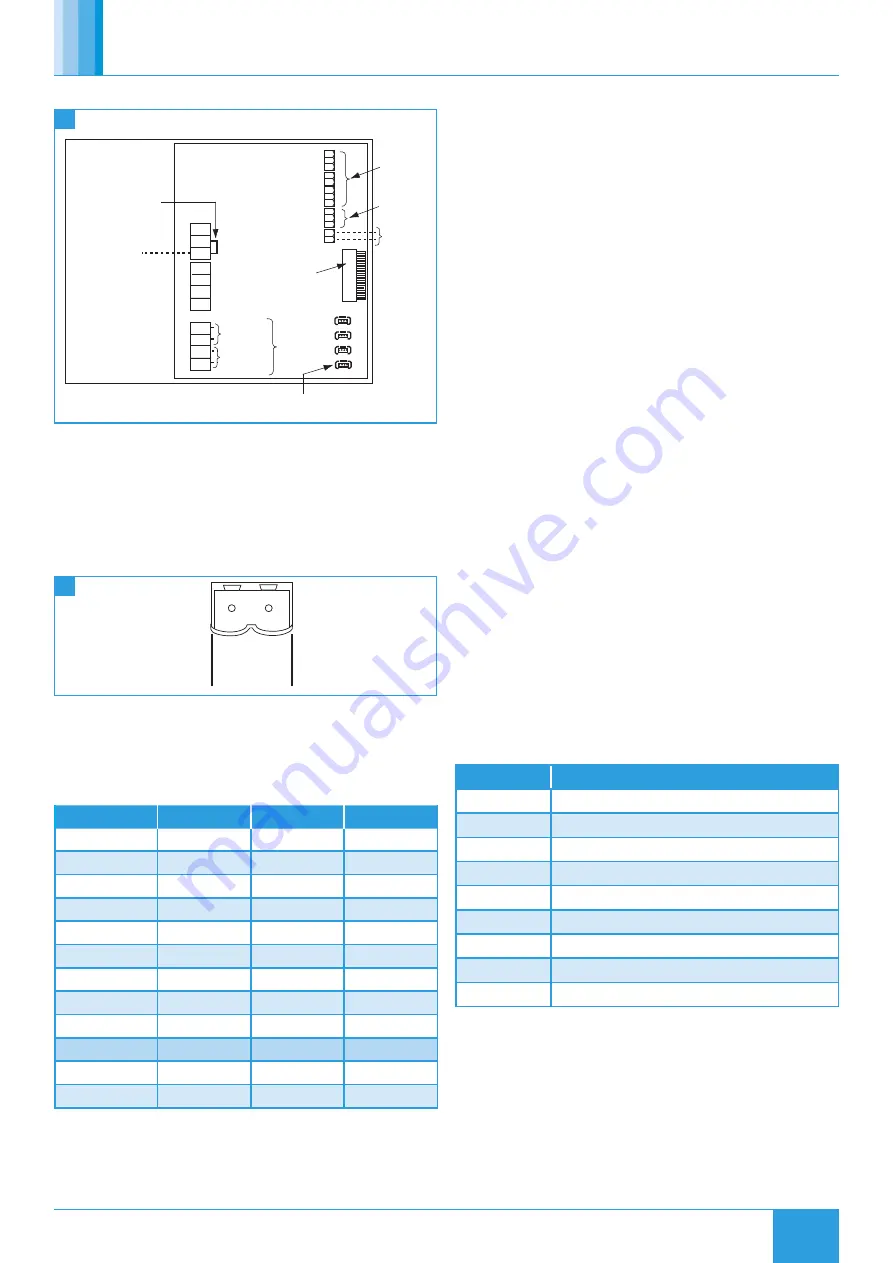

6.5 Control Panel

Volt Free

0.5A inductive

Contact

RUN signal

5A resistive

Volt Free

Contact

FAULT signal

N

L

SL

DP

RUN

FA

U

LT

CL

N

RET

Switc

if a BMS is connected.

Also remove link if an

enabling device is

connected in the 'NET'

Remove this link wire if

a switched live signal is

connected to terminal SL

NOTE: Also remove link

h live signal

(if required)

NET connections for

No user

ECOSMART devices

connections

connections

CO2 sensor

0

ECOSMA

RT NET

+ve signal

from BMS

Ribbon cable

to commissioning

box

230V 1ph 50Hz supply / 220V 1ph 60Hz supply

11

PCB Details

6.5.1 BMS Input Signals

The BMS connection is made with a plug-in connector via the socket. To

ensure the connection is made only by suitably qualified and authorised

personnel the plug is not supplied.

Plug-in BMS connector is available from:

R S Components, Part No. 403-875 or

Farnell, Part No. 963-021

0 - 10V

0V

BMS

12

BMS Connection

Reversal of the BMS connection will damage the control.

The system’s response to a 0-10V dc BMS signal is given in the table

below.

Note the BMS signal will override any sensors and user

control connected in the system. The voltage tolerance is +/-

125mV and is measured at the fans terminal.

Ventilation

Cooling mode * Heating mode *

Local Control

0.00

-

-

OFF / Trickle

0.25

-

-

Speed 1

0.50

0.75

1.00

Speed 2

1.50

1.75

2.00

Speed 3

2.50

2.75

3.00

Speed 4

3.50

3.75

4.00

Speed 5

4.50

4.75

5.00

Speed 6

5.50

5.75

6.00

Speed 7

6.50

6.75

7.00

Speed 8

7.50

7.75

8.00

Speed 9

8.50

8.75

9.00

Speed 10

9.50

9.75

10.00

*Only available on relevant unit

7.0 MAINTENANCE

Isolation - Before commencing work, make sure that the unit and

Nuaire control are electrically isolated from the mains supply.

It is important that maintenance checks are recorded and that the

schedule is always adhered to, in all cases, the previous report should

be referred to.

Motors are fitted with sealed for life bearings and do not require any

lubrication.

7.1 Routine Maintenance

•

Remove the top or the bottom cover and carefully clean out the

interior as necessary.

•

Check all parts for security and that the impeller rotates freely,

taking care not to disturb the balance.

•

The filter (where applicable) will require cleaning on a regular

basis. The frequency of the cleaning operation will depend on the

site conditions.

•

Ensure all control components are secure and clean.

•

Refit the cover.

7.2 Annually

•

All electrical terminals within the unit should be tightened.

•

Check all earth connections.

7.3 Dirty Filter Alarm (Extended Case Models Only)

Units pre fitted with a panel air filter are equipped with an visual Red

LED alarm on the side of the control. The pressure switch is pre set at

150pa and positioned within the unit and accessed via the removable

top or bottom panel. If required, the alarm signal can be positioned to

another area by others using the pre fitted terminal block - A volt free

relay must be used between the control and customer wiring.

LED On

= Pressure exceeds the maximum allowable final pressure drop.

Replacement filter part numbers are shown below.

7.4 G3 Filter Replacement (Extended Case Models Only)

Unit

Replacement Part Number

DE1A-ES

D1A-G3FILTERKIT

DE2A-ES

D2A-G3FILTERKIT

DE2HA-ES

D2HA-G3FILTERKIT

DE3A-ES

D3A-G3FILTERKIT

DE4A-ES

D3A-G3FILTERKIT

DE4HA-ES

D4HA-G3FILTERKIT

DE5A-ES

D5A-G3FILTERKIT

DE6A-ES

D6A-G3FILTERKIT

DE7A-ES

D7A-G3FILTERKIT