Installation and Maintenance

AXUS SVT2 High Temperature Impulse Axial Fans

2

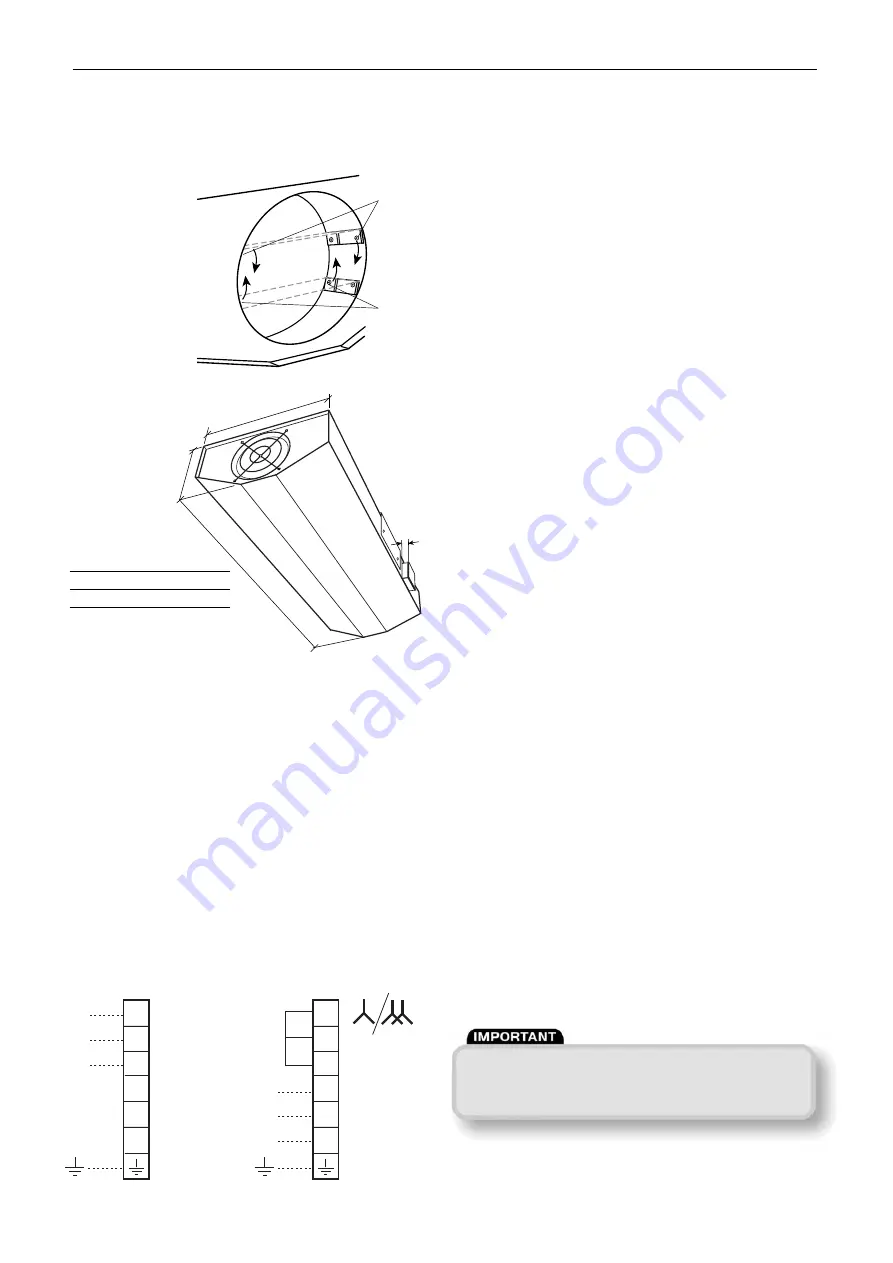

3) Adjusting the SVT2 Deflector blades

The Deflector blades are factory set for horizontal discharge

(default setting) but can be adjusted for downward deflection

using the following procedure.

1. Adjust top blade (A)

by removing the

2 screws at the front

either side of the blade,

tilt down and replace

the screws.

2. Adjust bottom blade

(B) by removing the

2 screws at the back

either side of the blade,

tilt upwards and replace

the screws.

Dimensions (mm)

Electrical Information

Motors are totally enclosed and protected to IP55 (Dust and

low pressure water jets). Motors comply with BS5000,

EN600034 and IEC34-1. Enclosures are to IP55 with class H

insulation. Motors are tested in accordance with EN12101-3

2002.

N.B. Please note the requirements for maintenance of

the motor. Failure to comply with the recommendations will

invalidate any warranty claim.

Wiring

Electrical supply wiring connection is to an externally mounted

terminal box on the case exterior. The box is pre-wired to the

motor with heat resisting cable.

NOTE: If a two speed starter is used it must have 3 contactors.

Individual wiring diagrams are included with each unit.

A matched Nuaire Inverter Speed Control is available. Please

contact Nuaire.

Two speed 3 phase TAP/PAM wound motors (D.O.L.

starting both speeds)

Leaflet Number 671409 February 2009

Connection details

Check that the voltage full load and starting current on the fan

rating label is suitable for your supply.

Two speed motors

Two speed motors are supplied Tap or Pam single winding.

All two speed types are designed for Direct On Line starting

on both speeds only unless otherwise specified.

Note: Tap wound motors require a three contactor control.

Individual wiring instructions are included with each unit.

Start up procedure

Ensure that the impeller rotation follows the label arrow

indicator on the casing. Should the direction be incorrect on

three phase units, reverse any two of the supply leads. Care

should be taken to set correct rotation as incorrect rotation

may result in damage to the motor. Equipment should be run

for approx. 30 minutes to ensure correct operation. If any fault

occurs, the equipment should be switched off.

Do not re-start

until the fault has been rectified.

Maintenance

General

Nuaire recommends all products maintained in accordance with

the HVCA “Standard Maintenance Specification for Mechanical

Services in Buildings” - Volume II Ventilating and Air

Conditioning. For guidance only due to the different periods

of operation from the time of installation and conditions of

use, no rigid inspection and maintenance periods can be

recommended. We suggest, therefore that the inspection and

if necessary cleaning should be carried out at regular intervals

of 1000 hours of operation or 3 months, whichever is the sooner.

For a routine inspection, check the tightness of all nuts, keys,

grub screws and endbolts etc. Remove any build up of dirt or

dust with a brush.

Motors

On going maintenance - Induction motors, by their very nature

require minimal maintenance. However, a regular regime of

inspection is recommended to ensure minor problems do not

escalate into breakdowns. Typical intervals would be 1000

hours of operation or 3 months, whichever is the sooner.

Checklist

■

No visible damage i.e. impeller cracked, fan cowl bent, foot

cracked etc.

■

No accumulation of dust or fibres on the frame or around

the fan inlet.

■

No significant corrosion of the lifting lugs/eyebolts.

■

No excessive vibration.

■

No loose fasteners.

■

Cables and earths are sound.

■

Sealing of the motor and gland plate in good condition.

■

Insulation resistance adequate, imperative this is checked

after prolonged shutdown.

1U

1V

1W

2U

2V

2W

400V 3 phase

50Hz supply

Link

(if no control

is used)

High speed

Low speed

L1

L2

L3

1U

1V

1W

2U

2V

2W

L1

L2

L3

For good EMC engineering practice, any sensor cables

or switched live cables should not be

placed within 50mm of other cables or on the same

metal cable tray as other cables.

C

B

A

Terminal

Box

55mm

Dimensions A x B x C

SVT2-1

2300 x 320 x 700*

SVT2-2

2300 x 403 x 700*

*Please allow an additional 55mm

for the width of the Terminal Box.

Figure 4.

Figure 5.

To adjust

Deflector

Blade (A)

To adjust

Deflector

Blade (B)