NDFL100-38 / BR003211 / Rev. 220900A

Page 22

One quick press of the PGM button, the display

changes to show the set point as the larger red

digits and the SPI in the lower small green digits.

Alter the red display using the up/down buttons to

show the new required set point, press exit or let

the unit time out to return to the basic display

which should be the new set point figure.

To enter a new parameter

The parameters dictate the way in which the burner

firing rate alters in response to changes in the

pressure/temperature of the boiler.

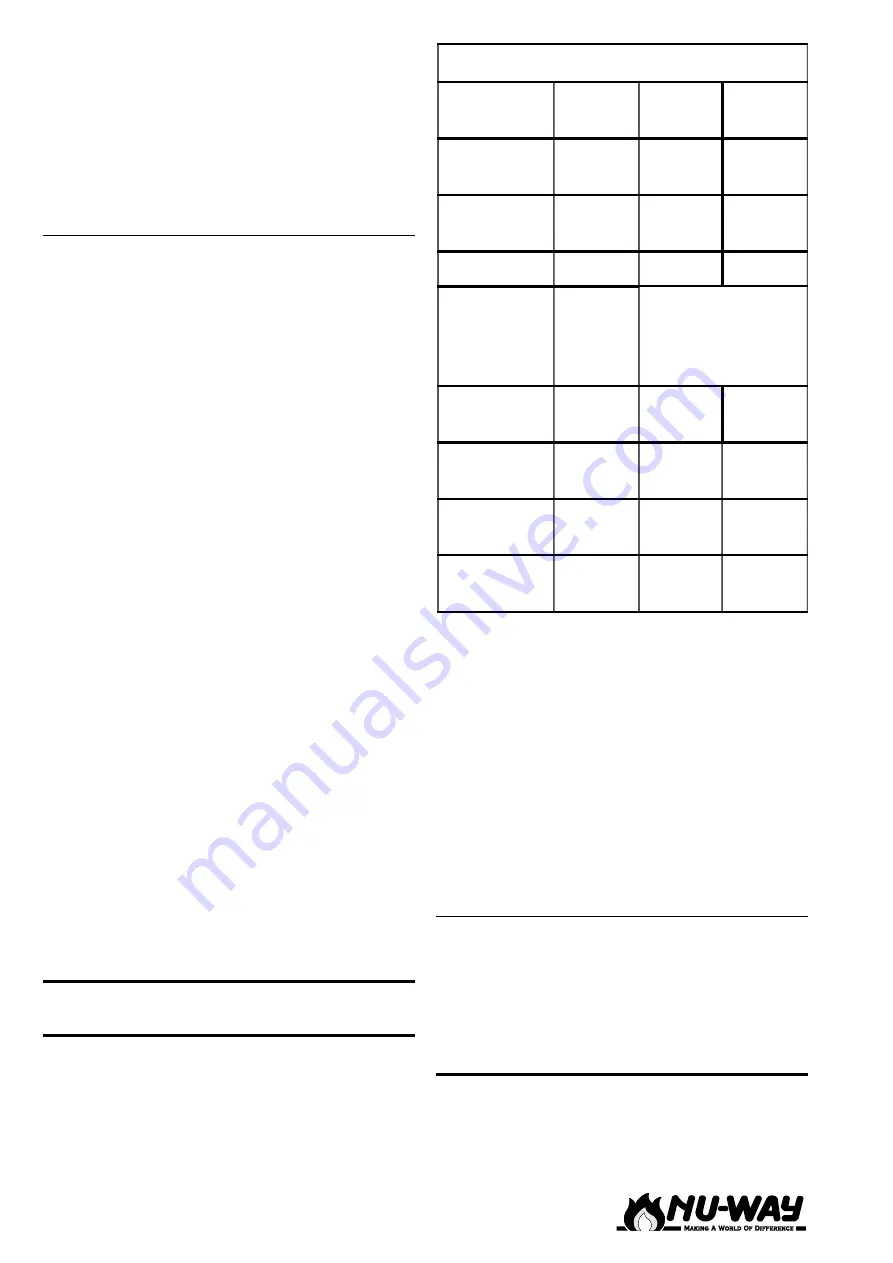

A major factor that determines the need to change

the parameters is if the burner is fitted to a steam

or hot water boiler. The table below indicates the

parameter and its setting for steam and hot water

boilers. It must be emphasised that it is only an

indication and any departure from these settings

should be made in small increments, with time

given to see how the burner is reacting to the

changed parameter.

Press and hold the PGM button down until the

green set point figure changes to an AL, the larger

upper figures show the value. Use the up/down

buttons to set the new value, press the PGM button

to enter the value and change to the next screen.

To cancel an entry press exit. Scroll through the

screens, (PGM button) modifying any value found

to be in error (up/down buttons). At the last screen

the PGM button will return the controller to the

original operating display.

At any point in the procedure the original operating

display can be obtained by letting the unit time

out, the value in the display at the time out will be

accepted.

A value can only be altered within the permitted

range of that parameter. All other parametrs must

remain as supplied.

Note: The detector range parameters SCL & SCH

are given as °C for Hot Water (temperature) and

bar for Steam (pressure).

NDFL - O

IL

O

PERATION

There are three atomising nozzles. The top nozzle

only sprays on low flame whilst two spray together

for the intermediate flame and all nozzles spray

on high flame. The oil operating pressure is 300

psi.

5:)

5

(&200(1'('

6

(77,1*6

3DUDPHWHU

'LVSOD\

+RW

:DWHU

6WHDP

3URSRUWLRQDO

EDQG

3E

'HULYDWLYH

WLPH

'W

5HVHWWLPH

5W

$FWXDWRU

WLPH

7W

6HWWRWKH$LU

'DPSHUUXQQLQJ

WLPHEHWZHHQORZ

KLJKIODPH

6ZLWFKRQ

WKUHVKROG

+\V

8SSHURII

WKUHVKROG

+\VW

'HWHFWRU

UDQJHVWDUW

6&/

'HWHFWRU

UDQJHHQG

6&+

At the start of the firing cycle, there is a pre-purge

with forced air and ignition. At the end of this

period, the air damper moves from the high fire

position to the ignition position. After a delay, the

low flame and safety (if fitted) solenoid valves are

energised, allowing oil to flow. The burner will light,

and the ignition is switched off. After a stabilising

period, the air damper moves to the low fire

position. If the flame fails to establish the burner

will go to lockout. If there is flame failure during

operation, the burner will shut down, and a single

restart cycle will follow.

Three-Nozzle System

When the air damper moves to the next pre-set

positions, the nozzle control valves open in

sequence. The burner will be held in any of the

three positions under the control of the boiler

thermostats.

C

OMMISSIONING

THE

B

URNER

Check that the electrical wiring is complete and

complies with all applicable Codes and Standards.

Check that the fuses are fitted and correctly sized.

Содержание NDFL100-38

Страница 34: ...NDFL100 38 BR003211 Rev 220900A Page 34 NOTES...

Страница 35: ...Page 35 NDFL100 38 BR003211 Rev 220900A...