GENERAL RULES

The installation of an oil burner should

be carried out in accordance with

local regulations. The installer of the

burner must therefore be aware of all

regulations relating to oil and combu-

stion.

Only oil suitable for the burner should

be used and then in combination with

a suitable oil filter before the oil pump

of the burner.

If the burner is replacing an existing

burner make sure that the oil filter is

replaced or cleaned. The installation

must only be undertaken by experien-

ced personnel.

INSTALLATION INSTRUCTIONS

General installation instructions ac-

company the burner and should be

left in a prominent place adjacent to

the burner.

ADJUSTMENT OF BURNER

The burner is from the factory pre-set

to an average value that must then be

adjusted to the boiler in question.

All burner adjustments must be made in

accordance with boiler manufacturers

instructions.These must include the

checking of flue gas temperatures,

average water temperature and CO

2

or

O

2

concentration.

To adjust the combustion device, start

by increasing the air volume and the

nozzle assembly somewhat.When the

burner starts it is burning with excess

air and smoke number 0. Reduce the

nozzle assembly adjustment until soot

occurs, and then increase the

adjustment to make the soot disappear

again. Then the volume of air is reduced

until soot occurs and increased again

to reach a combustion free of soot.

By this procedure an optimum adjust-

ment is obtained. If larger nozzles are

used the preadjustment of both the air

volume and the nozzle assembly must

be increased.

A whistling sound may be heard which

can be eliminated or reduced as fol-

lows: Increase the nozzle assembly

adjustment somewhat. The CO

2

-con-

tent and consequently the air volume

will then be reduced.

CONDENSATION IN CHIMNEY

A modern burner works with less ex-

cess air and often also with smaller

nozzles than older models. This

increases the efficiency but also the

risk of condensation in the chimney.

GENERAL INSTRUCTIONS

MAINTENANCE

The boiler/burner should be examined

regularly for any signs of malfunction or

oil leakage

OIL SUPPLY

The oil line should be dimensioned in

accordance with the pump

manufacturer´s instruction. In the

suction line to the burner a filter should

be mounted to prevent any particles

in the oil from reaching the burner. If

the installation consists of several

burners each one should have its own

suction line from the tank or a

circulation system should be used.

The temperature in the oil line should

be kept as constant as possible. Avoid

exposing the line to excessive cold

which may cause blockages of paraf-

fin deposits.

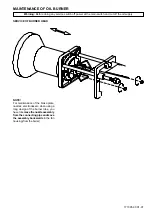

The oil pipe and electric cable should

be fitted so that the burner can be

placed on the floor for inspection of

the combustion device.

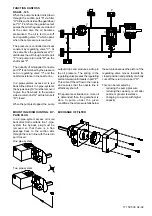

ADJUSTMENT OF NOZZLE

ASSEMBLY

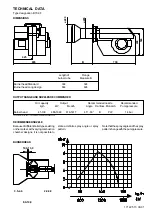

A Adjustment Stage 1 and Stage 2.

B Adjustment Stage 3.

The risk increases if the area of the

chimney flue is too large. The tempera-

ture of the flue gases should exceed

60°C measured 0,5 metres from the

chimney top.

Measures to raise the temperature:

Insulate the chimney in cold attics

Install a tube in the chimney

Install a draught regulator (dilutes the

flue gases during operation and dries

them up during standstill)

Increase the oil quantity

Raise the flue gas temperature by

removing turbulators, if any, in the

boiler.

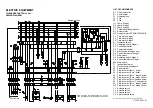

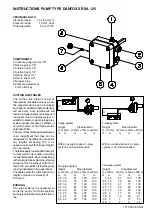

PUMP ADJUSTMENT

See separate description.

AIR ADJUSTMENT

See page "Air adjustment with

damper motor".

171 305 94 98-02

A

B

ADJUSTMENT OF NOZZLE

ASSEMBLY

Содержание MOL 1650-3R B70 2-3

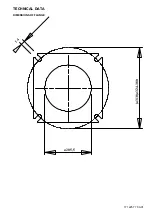

Страница 4: ...TECHNICAL DATA DIMENSIONS OF FLANGE 171 225 77 00 01 14 310 324 380 205 5...

Страница 14: ......

Страница 16: ...NOTES...

Страница 17: ...NOTES...