User Manual

Rewinder XLP 51x

FUNCTIONING

Rotational speed

During winding, the rotational speed is controlled via the deflection of the dancer arm from the rest

position. The greater the deflection, the lower the rotational speed. If the label material sags – the

dancer arm is in this case only slightly deflected – the rewinder increases the rotational speed in order

to make up the “delay”. This ensures that the label material is rolled up evenly tautly. Without lateral

deflection - e.g. when the material is finished – the rewinding process stops after about four seconds.

In the mode “Printing inside”, material does not wrap itself around the dancer arm as much as is the

case with “Printing outside”. Particularly with larger roll diameters, the dancer arm would often shoot

from one extreme position to the other. The material would then be wound up in a jolting manner.

For this reason, the software is adjusted when “Printing inside” is selected – it then only uses ap-

proximately 50% of the maximum dancer arm deflection for controlling the motor.

Direction of rotation

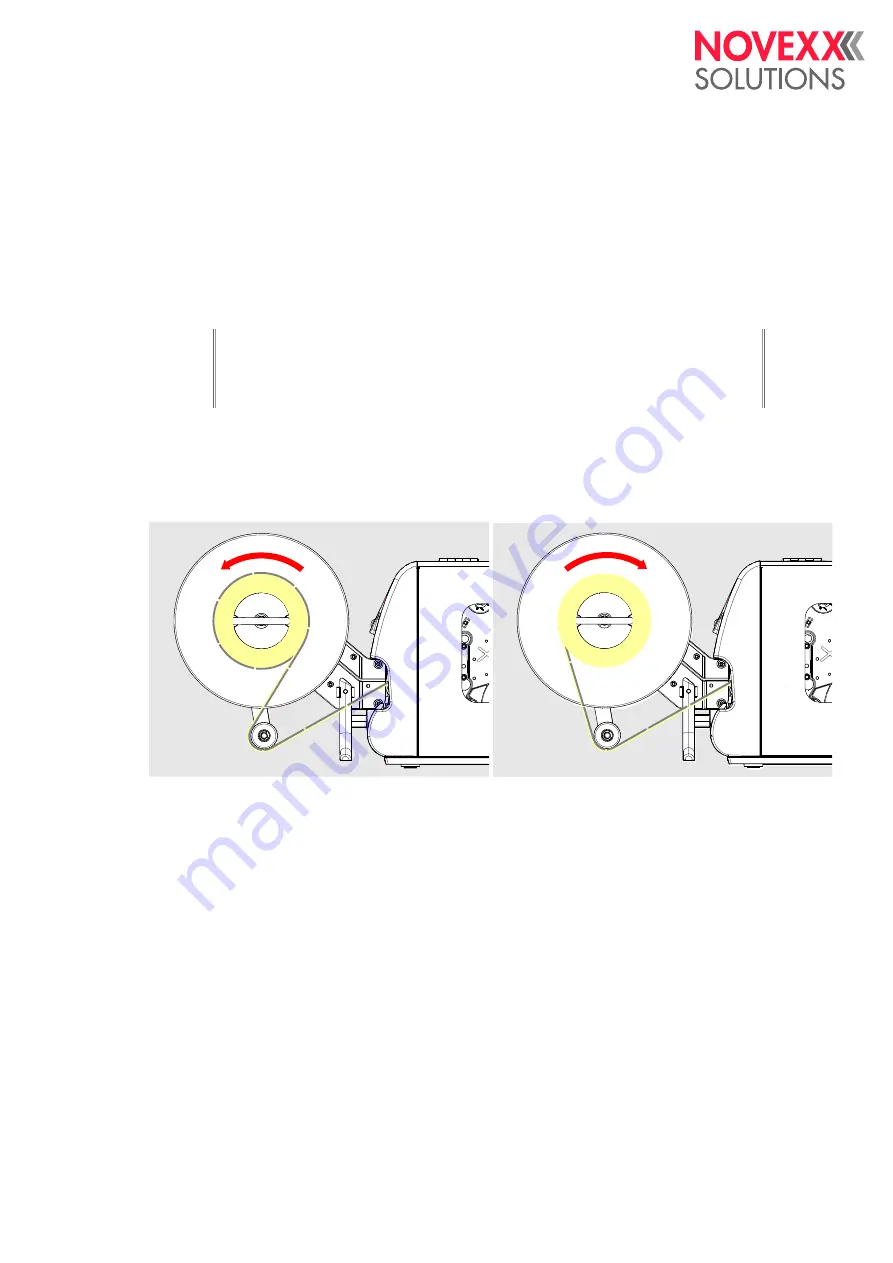

The label material can be alternately rolled up with the labels facing outwards (left picture) or inwards

(right picture) by reversing the direction of rotation.

Fig. 2: Rotation direction “Printing outside” (left) and “Printing inside” (right).

Rotational speed

The rotational speed of the rewinder depends on the print speed. A low print speed leads to a slower

rewinder rotation as a high print speed. An exception to this rule is the rotational speed directly after

starting the wind-up process.

Edition 2b - 9/2021

5

Product description

Functioning