4

Supply water pressure limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40-100 psi (280-689 kPa)

Supply water temperature limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40-100 °F (4.5-37.7°C)

Maximum total dissolved solids (TDS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2000 ppm

Maximum water hardness @ 6.9 pH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 gpg

Maximum iron, manganese, hydrogen sulfide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0

Chlorine in water supply (max. ppm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.0

Supply water pH limits (pH) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Product (quality) water, 24 hours

1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18.4 gal. (69.6 liters)

Percent rejection of TDS, minimum (new membrane)

1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86.5

Automatic shutoff control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . yes

Efficiency

2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12.2 %

Recovery

3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22.9 %

This system conforms to NSF/ANSI 58 for the specific performance claims as verified and substantiated by test data.

1

@ Feed water supply at 50 psi, 77°F, and 750 TDS --- Quality water production, amount of waste water and percent rejection

all vary with changes in pressure, temperature and total dissolved solids.

2

Efficiency rating means the percentage of the influent water to the system that is available to the user as reverse osmosis treat-

ed water under operating conditions that approximate typical daily usage.

3

Recovery rating means the percentage of the influent water to the membrane portion of the system that is available to the user

as reverse osmosis treated water when the system is operated without a storage tank or when the storage tank is bypassed.

Non-potable Water Sources:

Do not attempt to use this product to make safe drinking water from non-potable water sources.

Do not use the system on microbiologically unsafe water, or water of unknown quality without an adequate disinfection before or

after the system. This system is certified for cyst reduction and may be used on disinfected water that may contain filterable

cysts.

Arsenic Reduction:

This system shall only be used for arsenic reduction on chlorinated water supplies containing detectable

residual free chlorine at the system inlet. Water systems using an inline chlorinator should provide a one minute chlorine contact

time before the reverse osmosis system.

Nitrate/Nitrite Test Kit:

This system is acceptable for treatment of influent concentrations of no more than 27mg/L nitrate and

3mg/L nitrite in combination measured as N. It is certified for nitrate/nitrite reduction only for water supplies with a pressure of 280

kPa (40 psig) or greater. This system is supplied with a nitrate/nitrite test kit. Product water should be monitored periodically

according to the instructions provided with the test kit.

TDS Test Kits:

TDS test kits are available by calling 1-800-949-8220, or check the water testing section of your local phone

directory.

Installations In The Commonwealth Of Massachusetts:

The Commonwealth of Massachusetts requires installation be per-

formed by a licensed plumber and do not permit the use of saddle valves. Plumbing code 248--CMR of the Commonwealth of

Massachusetts must be followed in these cases.

Product Water Testing:

The Reverse Osmosis System contains a replaceable treatment component critical for the effective

reduction of total dissolved solids. Product water should be tested periodically to verify that the system is performing properly.

Replacement of the reverse osmosis component:

This reverse osmosis system contains a replaceable component critical to

the efficiency of the system. Replacement of the reverse osmosis component should be with one of identical specifications, as

defined by the manufacturer, to assure the same efficiency and contaminant performance.

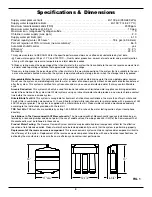

Specifications & Dimensions

12-1/4"

4-3/4"

13"

11" dia.

16"

4-3/4”

13”

16”

12-1/4”

11” dia.

FIG. 1