www.nordsonefd.com [email protected]

800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

781Mini Series Spray Valve

12

Cleaning the Wetted Parts (continued)

Reassemble the Wetted Parts

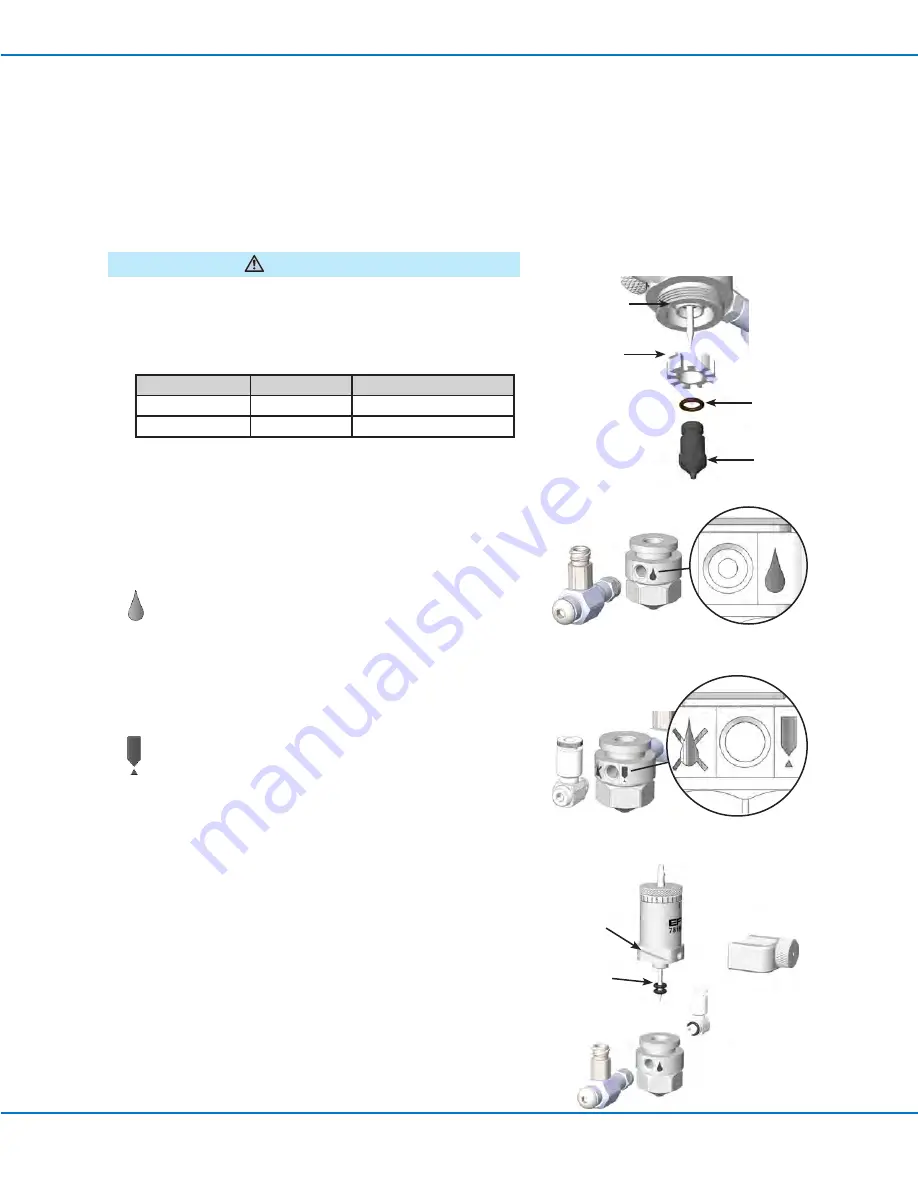

1. Lubricate the nozzle O-ring with fluorocarbon grease and

reassemble the nozzle components.

CAUTION

Do not over-tighten the nozzle. Doing so can damage the assembly.

2. Reinstall the nozzle assembly, ensuring that the dispersion

ring tab fits into the notch on the fluid body. Depending on the

nozzle material, tighten the nozzle to the following torque:

Nozzle Size

Material

Torque

0.01" (0.254 mm)

Stainless steel

1.4 N•m (12 in.-lb)

0.03" (0.76 mm)

PEEK

0.1 N•m (1 in.-lb) max.

Service (continued)

Correct installation location for the

fluid inlet fitting

Correct installation location for the

nozzle air fitting

3. Install the fluid inlet fitting in the fluid inlet side of the fluid body.

If installing a 90° fluid inlet fitting, refer to “Installing a 90° Fluid

Inlet Fitting” on page 7 to install the fitting in the desired

orientation. Return here to continue.

NOTE:

Ensure that the fluid inlet fitting is installed on the

fluid inlet side of the fluid body. A fluid symbol indicates the

fluid inlet.

4. Install the nozzle air fitting in the fluid body.

NOTE:

Ensure that the nozzle air fitting is installed on the air

inlet side of the fluid body. An air symbol indicates the air

inlet.

5. Install a replacement double-stacked O-ring set on the needle.

NOTE:

Lubricate double-stacked O-rings before installing.

Use the supplied fluorocarbon grease only if the assembly fluid

being dispensed is compatible with it.

6. Use one hand to position the fluid body on the air cylinder /

needle assembly and then slide the QR clasp into the grooves

on the air cylinder body.

Nozzle (PEEK

nozzle shown)

Nozzle O-ring

Dispersion

ring tab

Notch on

fluid body for

dispersion ring tab

Groove for

QR clasp

Double-

stacked

O-rings