4

It should be noted that the machines hydraulic systems operate at

extremely high potentially dangerous pressures. Every effort should

be made to relieve any system pressure prior to disconnecting or

removing any portion of the system. Relieve system pressure by

cycling the applicable control lowering button several times with the

motor stopped and ignition on, to direct any line pressure back into

the reservoir. Pressure feed lines to system components can then

be disconnected with minimal fluid loss.

Remove all rings, watches and jewelery when performing any maintenance.

Wear well-fitting helmet, safety shoes and working Clothes When

drilling grinding or hammering always. Wear protective goggles.

Always do up safety clothes properly so that they do. Not catch on

protruding parts of machines. Do not wear oily clothes. When

checking, always release battery plug. DO NOT WEAR LONG

HAIR UNRESTRAINED, OR LOOSE-FITTING CLOTHING AND

NECKTIES WHICH ARE APT TO BECOME CAUGHT ON OR

ENTANGLED IN EQUIPMENT.

During maintenance do not allow any unauthorized person, to

stand near the machine.

Flames should never be used instead of lamps. Never use a buring

flame to check leaks or the level of oil or electrolyte.

Immediately remove any oil or grease on the floor of the operator’s

compartment or on the handrail. It is very dangerous if someone slips

while on the machine.

Always use the recommended pure oil or grease, and be sure to use clean containers.

Oil is a dangerous substance. Never handle oil, grease or oily

clothes in places where there is any fire or flame. As

preparation for use of fire extinguishers and other fire- fighting

equipment.

Keep the battery away from fire hazards. The generated gases

are explosive.

Store all the oils in a specified place.

Keep the flammable things away from the machine. Do not

smoke in the working site.

Battery should always be disconnected during replacement of electrical components.

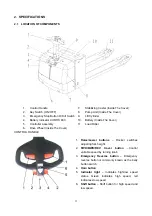

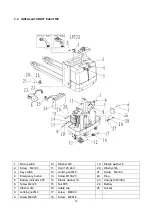

Содержание LPT22

Страница 1: ...NOBLELIFT EQUIPMENT Service Maintenance Manual LPT22 Power Pallet Truck V LPT22 01 00 Date 2011 02 26 ...

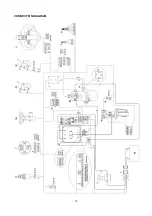

Страница 15: ...14 3 ELECTRICAL SYSTEM 3 1 ELECTRICAL DIAGRAM WIRING DIAGRAM ...

Страница 16: ...15 CONNECTION DIAGRAM ...

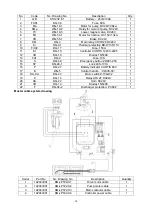

Страница 30: ...29 3 7 CURTIS CONTROLLER ...

Страница 63: ...62 8 2 TROUBLE SHOOT ...

Страница 64: ...63 ...

Страница 65: ...64 ...