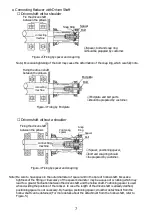

■ Q Type (with Brake)

■Structure of brake

0.1kW, 0.2kW and 0.4kW

①Field

②Armature

③Outer Disk

④Spring 1

⑤Spring 2

⑥Castellated Nut

⑦Key

⑧Hex Socket Head Cap bolt

⑨Brake Cover

⑩Brake cover setting bolt

※

Proper Gap: 0.4mm (±0.1mm)

Gap for Suction Limit: Less than 0.7mm

0.75kW

①Field

②Armature

③Outer Disk

④Spring 1

⑤Spring 2

⑥Castellated Nut

⑦Key

⑧Hex Socket Head Cap bolt

⑨Brake Cover

⑩Brake cover setting bolt

※

Proper Gap: 0.2mm (±0.1mm)

Gap for Suction Limit: Less than 0.5mm

As a result of using brake for an extended period of time, naturally brake

gap grew and finally brake releasing become impossible. To avoid this

trouble, be sure to adjust brake gap periodically.

As a result of using brake for an extended period of time, naturally brake

gap grew and finally brake releasing become impossible. To avoid this

trouble, be sure to adjust brake gap periodically.

After operation for an extended period of time, the friction disk of brake becomes

abraded and the gap increases. When the gap clearance becomes greater than the limit of

gap to inhale, armature inhaling becomes difficult by magnet, making it impossible to

release the brake. When using the motor continuously with this condition, the operation

with brake-on causes overload and finally ALARM LED on the driver lights up, then the

motor will stop. In order to operate this machine safely, it is recommended to check or

adjust the brake gap periodically (Every 1 year or every 2 to 3 million cycles).

①

⑧

⑤

⑦

④

⑥

②

⑨

⑩

③

gap

③

①

⑧

⑤

⑦

⑥

②

④

⑨

⑩

gap

12

Содержание GTR-AR APQ

Страница 1: ...APQ Type Gearmotor Instruction Manual...