USER MANUAL

14

33014816(1)2005-07 A

CLEANING AND MAINTENANCE

The machine cleaning can be carried out by non-specialized

personnel. However, the person in charge of the cleaning

should be familiar with the energy source cut-off main

controls and the main features of the machine to avoid any

dangerous situation.

The machine maintenance should be carried out by highly

skilled personnel, with a deep knowledge of the machine and

its components.

Mechanical, electrical and electronic maintenance is

possible.

CLEANING

Machine general cleaning

Clean the coating, panels and controls of the machine with a

soft cloth, either dry or lightly soaked in a mild detergent

solution.

Remove traces of dust and other dirt from the machine control

panels (digital displays, indicator and warning lights,

switches).

If necessary, the electrical components should be cleaned

only by specialized personnel and non-corrosive products

suitable for electric circuits should be used.

PERIODICAL MAINTENANCE

For the engine maintenance, please follow the instructions

provided in the Use and Maintenance Manual concerning the

engine installed on the sweeper. This manual comes in a

special case.

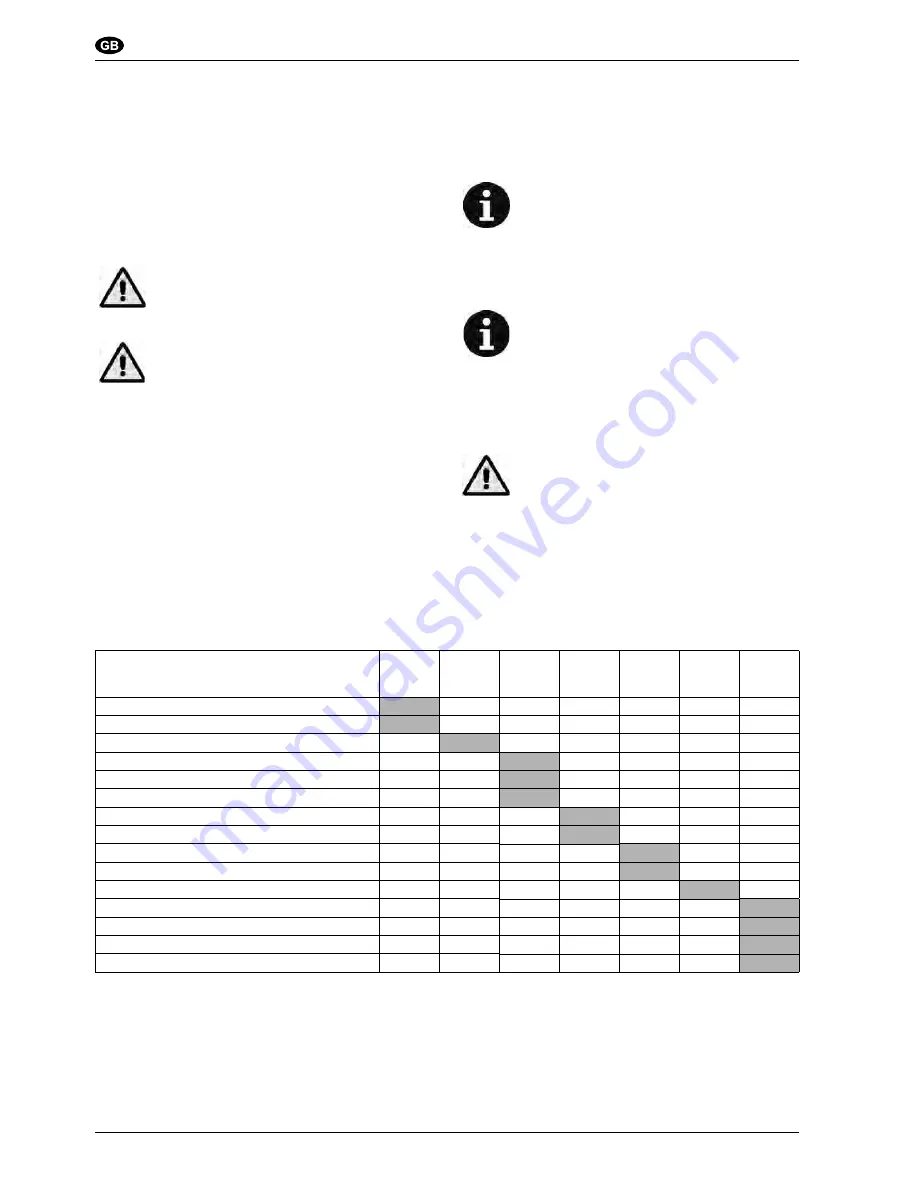

Recommended periodical maintenance operations are

summarized in this table.

MAINTENANCE TABLE

WARNING!

Any cleaning and maintenance operation

should be carried out with the machine off.

Wait for all the parts to stop and cool down.

WARNING!

Protect eyes and hair when cleaning the

machine with compressed air guns.

If the machine is working in a toxic

environment, wear a special mask and

adequate protective clothing when carrying

out maintenance work on the dust filter.

NOTE

Do not use solvents such as alcohol, petrol or

ethyl acetate as they could damage the

surfaces.

NOTE

Pay attention when cleaning the electrical

components.

WARNING!

Any cleaning and maintenance operation

should be carried out with the machine off.

Wait for all the parts to stop and cool down.

Maintenance

Every 10

hours

Every 20

hours

After 50

hours

Every 150

hours

Every 300

hours

Every

1,000

hours

Every

2,000

hours

Hydraulic oil level check

Closed pocket filter cleaning

Battery check

Brake fluid level check

Battery check

Dust control system water filter check

Gear pump hydraulic oil filter replacement

Hydrostatic pump hydraulic oil filter replacement

Hydrostatic pump hydraulic oil filter replacement

Screw tightening

Hydraulic oil change

Motor carbon brush check

Hydraulic motor and pump pressure check

Brake system check

Moving part clearance check

Содержание SR 1700 2WD B

Страница 3: ...33014816 1 2005 07 A B C ...

Страница 4: ...D E 1 1 2 16 18 17 4 14 11 3 8 6 10 9 6 8 7 12 13 15 5 ...

Страница 85: ...33014816 1 2005 07 A J 14 13 12 8 11 10 3 3 4 5 6 7 3 16 1 2 9 8 15 ...

Страница 86: ...33014816 1 2005 07 A K L M N O P 1 1 1 1 2 1 1 ...

Страница 87: ...33014816 1 2005 07 A Q R S T U V 1 3 1 2 1 1 1 1 2 ...

Страница 88: ...33014816 1 2005 07 A W X Y Z AA AB AC 1 1 1 1 1 1 ...

Страница 89: ...33014816 1 2005 07 A AD ...

Страница 90: ...33014816 1 2005 07 A AE ...

Страница 91: ...33014816 1 2005 07 A AF ...

Страница 92: ......

Страница 93: ...33014816 1 2005 07 A F 2 1 11 4 6 8 7 12 9 5 10 3 ...

Страница 94: ...G 3 5 8 7 4 6 11 1 12 9 2 10 13 ...

Страница 95: ...33014816 1 2005 07 A H I 10 12 2 3 7 9 4 1 5 11 8 4 1 5 11 8 2 9 13 10 12 3 7 6 6 ...