18 - FORM NO. 56041516 - ConvertaMAX

™

28/34, I-MAX

™

28HD/34HD, BA 750/850

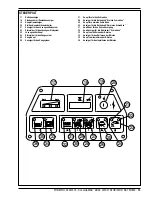

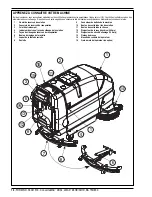

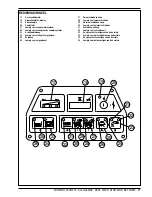

FUNCTIONAL DESCRIPTION OF CONTROLS:

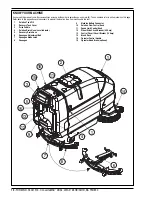

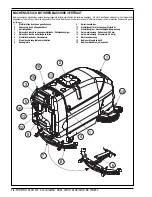

Solution Tank Fill (1) – Open to fill the solution tank, use non-foaming chemicals only.

Recovery Tank Cover (2) – Point of entry for waste water into tank. Also houses float ball which shuts off vacuum port to vac motor when tank is full.

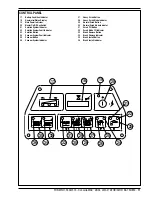

Drive Paddle (3) – Located on top at the rear of the machine, the operator can make the machine go forward by pushing forward on it, or reverse by pulling

backward on it. The speed is variable depending on how far forward or backward the paddle is moved. When the brush head is in the “DOWN” position, the

brushes and solution will operate when the drive is engaged in either direction, but will stop after the machine is stationary for 3 seconds.

Solution Drain Hose / Level Indicator (4) – Used to empty the solution tank and show current level of solution in tank, graduations are marked on the side

of the solution tank next to the hose.

Recovery Drain Hose (5) – Used to empty the recovery tank.

Squeegee Adjustment Bolt (6) – Used to adjust the tilt of the squeegee. Turn bolt clockwise to tilt the squeegee backwards and counter-clockwise to tilt it

forward.

Squeegee Blade Latch (7) – Holds rear squeegee blade and straps in place, release to replace rear blade.

Squeegee (8) – Picks up solution after scrubbing.

Machine Battery Connector (9) – Batteries plug into this connector, disconnect to charge batteries.

Solution Flow Control Knob (10) – Turn this dial to the right to decrease solution flow to the floor. Turn to the left, to increase the amount of solution flow to

the floor. When the Drive Paddle (3) is released from either forward or reverse travel, the solution flow will stop automatically, and resume when the drive is

engaged.

Speed Limit Control Knob (11) – The Speed Limit Control Knob is used to adjust the maximum speed in both forward or reverse.

Wheel Drive Circuit Breaker (12) – Provides overload protection to machine’s wheel drive motor. If it trips, it will pop out. To reset, wait one minute and press

the button back in. If any breaker trips repeatedly, have the machine serviced.

Control Circuit Circuit Breaker (13) – Provides overload protection. If it trips, it will pop out. To reset, wait one minute and press the button back in. If any

breaker trips repeatedly, have the machine serviced.

Brush Deck (14) – Contains brush drive motors and brushes.

Operator Control Handle (15) – Operator holds onto this to control the machine.

Operator Hand Brake (optional) (16) – Use to prevent machine from rolling.