2

– English

English

2

– English

The devices of this kit and other optional accessories belong to the Nice Home automation system and are designed to automate a sliding gate for

residential use.

CAUTION! – Any use other than that specified herein or in environmental conditions other than those stated in this manual is to be con

-

sidered improper and is forbidden

The kit comprises an electromechanical gearmotor with 24 V direct current; it is equipped with a mechanical release mechanism with key that allows

for manually moving the gate in case of a power outage. The gearmotor is equipped with a command control unit that manages the operation of all of

the automation.

Connection of the control unit to the various devices occurs through the ECSBus system (a single cable with 2 wires).

The control unit can be powered by fixed mains power (230 V) or, alternatively, through the SOLEKIT photovoltaic system of the Nice Home range. If

powered from the mains, it can be fitted with a back-up battery (mod. PR100, optional accessory) which ensures that the automation can execute a

certain number of manoeuvres during the hours following a power outage.

2

PRODUCT DESCRIPTION AND INTENDED USE

3

INSTALLATION

Certain devices and accessories mentioned in this manual are optional and not included in the kit.

The end stops are not included in the kit and do not belong to the Nice Home range of products.

Consult the Nice Home product catalogue or visit the website www.niceforyou.com

3.1 - VERIFYING THE SUITABILITY OF THE GATE AND ENVIRONMENT

• Ensure that the mechanical structure of the gate is suitable for automation and complies with local standards; consult the technical data appearing on

the gate’s label.

This product cannot automate a gate that is not already secure and efficient; moreover, it cannot resolve defects caused by improper

installation of the gate or poor maintenance of the latter.

• Manually move the gate leaf in both directions (open/closed) and make sure that the movement takes place with constant friction at every point along

its course (there should be no points requiring more or less effort).

• If the door includes an access door, make sure that it does not obstruct normal movement; mount a suitable interlock system if necessary.

• Manually bring the door of the gate into any position then leave it closed and make sure that it does not move.

• Check that there is no risk of derailment or that the gates may come off their guides.

• Check that there is sufficient space where the gearmotor is installed to allow for effecting a manual release manoeuvre.

• Make sure that the area where the gearmotor is secured is not subject to flooding; if necessary, mount the gearmotor adequately raised from the

ground.

• Check that the installation surfaces of the various devices are solid for guaranteeing a stable anchorage and that they are protected and guarded

against accidental knocks. For the photocells, choose a flat surface capable of guaranteeing proper alignment of the pair (Tx and Rx).

3.2 - VERIFYING THE PRODUCT’S APPLICATION LIMITS

Before proceeding with the installation, carry out the following checks and verify the "Product technical characteristics" (Paragraph 3.3):

01.

Check that the dimensions and weight of the gate leaf fall within the following limits:

FILO400C: maximum length 5,5 m; maximum weight 400 kg

FILO600C: maximum length 7 m; maximum weight 600 kg

02.

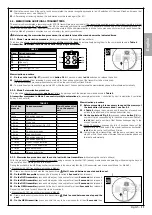

Check the overall dimensions of the gearmotor (

Fig. 2

). Note – These measurements also serve as reference to calculate the space required for

the foundation excavation for the passage of the cable trays.

03.

Check that the estimated durability is compatible with the intended use (Paragraph 2.5).

04.

Ensure that all limitations, conditions and warnings appearing in this manual can be fully observed.

3.3 - PRODUCT TECHNICAL SPECIFICATIONS

Model type

FILO400C

FILO600C

Product type

Electromechanical gearmotor for automatic gate and door automations with incorporated con-

trol unit, inclusive of radio receiver for ECCO5 transmitters (various models)

Technology adopted

A 24 V motor

, reducer with helical gears; mechanical release mechanism. A transformer

inside the motor, but separate from the control unit, reduces the mains voltage to the nominal

24 V

voltage used throughout the automation system.

Peak thrust

10 Nm

13 Nm

Nominal torque

3.5 Nm

5.2 Nm

Speed (no load)

0.30 m/s

0.20 m/s

Nominal torque speed

0.20 m/s

0.15 m/s

Maximum frequency of cycles

24 cycles/hour at 55°C (40 at 25°C)

11 cycles/hour at 55°C (20 at 25°C)

Maximum continuous cycle time

30 minutes

15 minutes

Application limits

Its structural characteristics make it suitable

for use on gates weighing up to 400 kg and

up to 5.5 m long.

Its structural characteristics make it suitable

for use on gates weighing up to 600 kg and

up to 7 m long.

FILO400C/FILO600C mains power supply

230 V (+10% –15%) 50/60Hz

Maximum power input

370 W

420 W

Emergency power supply

Configured for model PR100 back-up batteries

Flashing light output

For flashing lights with 12 V (maximum 21 W) bulb

ECSBus output

One output with maximum load of 10 ECSBus units (1 ECSBus corresponds to the consumption

of a pair of photocells)

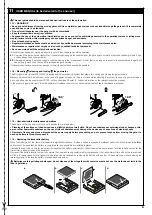

Step

A

Step

B