TRACE

MATE II-CTR

2.3

Chapter 2 Installation

Mounting the Controller

Mount the control panel with Unistrut brackets using

5/16” bolts. The Unistrut (or equivalent) mounting allows

air circulation to cool the heat-sink. This is important to

ensure proper operation of the TraceMate II-CTR.

Mounting dimensions are shown in Figure 2.5.

Wire Sizing

Conduit and Cabling

TraceMate II-CTR comes with two 0.843” and one

1.125” conduit knockouts located on the bottom of the

enclosure. Conduit hubs should be NEMA-4X rated, such

as T&B H075-0.75 and H125-1.25 or Myers equivalent,

to maintain a watertight seal. Unused knockouts should be

sealed using NEMA-4X rated seals.

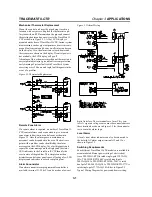

Power Wiring

The power input terminals supply power to both the heat

trace and controller. Size the power input wires

appropriately to the breaker size and maximum ambient

operating temperatures. Maximum breaker size is 30A.

Connect power wires to input terminals 1 & 2 for heater 1

and 17 & 18 for heater 2. See Figure 2.2. The breaker

should be placed as close as possible to the TraceMate II-

CTR.

The RTD probe is delicate and should not

be bent or used as a tool to puncture

insulation.

Wiring methods should comply with Canadian

Electrical or National Electrical Code and

local codes. Power and signal wires should not

be run in the same conduit system. Wiring

should be rated at least 90 °C, 300 V Min.

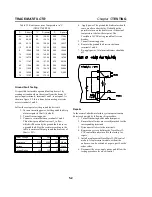

Wire Size (AWG)

Current Load (A)

Max. Ambient

Temperature (°C)

6

30

50

8

30

40

10

24

50

12

16

50

The supply voltage must be single-pole

120VAC for TM-2SIH1-RTD, single-pole

240VAC for TM-2SIH1-RTD-240V, dual-pole

208~240VAC for TM-2DIH2-RTD-208~240V,

and single-pole 277VAC for TM-2SIH1-RTD-

277V.

Wiring methods must conform to Class 1,

Division II or Class 1, Zone II requirements.

Heater Wiring

Connect heating cable wiring to terminals 3 & 4 for

heater 1 and 19 & 20 for heater 2. See Figure 2.2. If the

heating cable has a braid, it should be terminated to the

ground stud using a ring terminal suitable for #10 stud.

Figure 2.3 Ground Connection

Ground Connection

Connect the controller grounding stud directly to a ground

bus using the shortest, practical path. Use a tinned copper,

braided bonding cable such as Belden 8660. As a guide-

line, the ground cables should be minimum 96 strands,

number 34 AWG each.

To install the ground connection, remove the outside nut,

washer and #8 ring lug provided on the ground stud.

Crimp the ground cable onto the ring lug and re-assemble

onto the ground stud using the washer and nut.

Figure 2.4 RTD Mounting

RTD Sensor Wiring

RTD sensors should be 3-wire, 100 ohm, platinum to DIN

standard 43760. Mount the RTD element on the pipe,

away from the heat trace and 180° from the bottom of the

pipe. The total circuit resistance per conductor from the

RTD to the control panel must be less than 10 ohm.

Exceeding this resistance will result in a non-linear

temperature measurement. Beldon cable 8770 or

equivalent allows RTDs to be placed up to 1,000 feet

from the control panel. Complete all RTD wiring accord-

ing to Figure 2.2 Typical Wiring Diagram.