FORM NO. L-20341-E-0208

ALIGNMENT (SEE FIGuRE 2)

1. The Transmitter must be the upper unit with

the Receiver mounted below when used with a

horizontal web run.

2. The angle of inclination to the web must be 45° + 5

o

.

3. The Transmitter to Receiver gap must be

2.36 + 0.20 in. [60 + 5 mm].

4. The lateral displacement must be within 0.20 In.

[5 mm].

5. The angular displacement must be 3

o

.

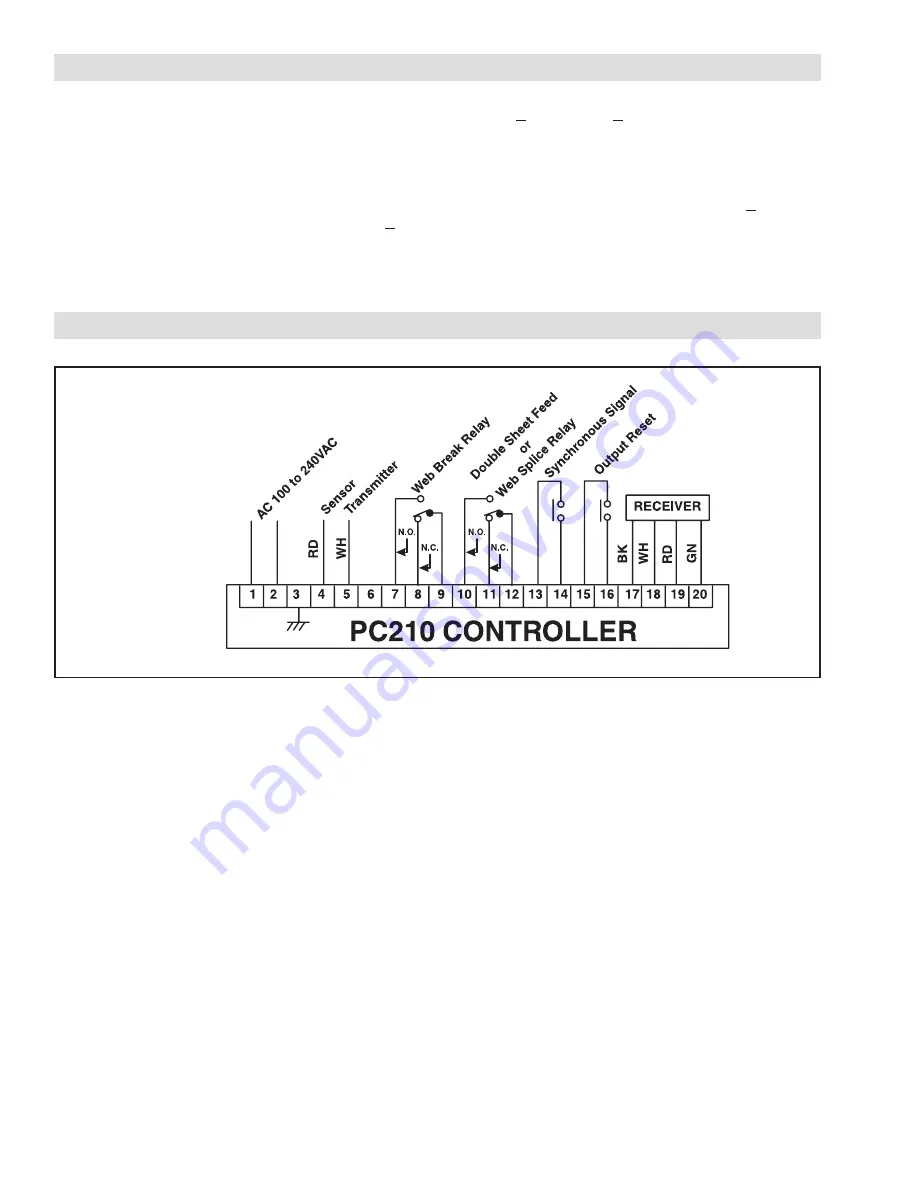

FIGuRE 3

1. Provide AC Power 100, 110, 120, 200, 220,

240VAC, 50 or 60 Hz at Terminals 1 and 2.

Connect the ground wire to Terminal 3 (See Figure

3).

2. Connect the Sensor Transmitter 16 ft. [5 m] cable to

Terminals 4 and 5 (See Figure 3).

NOTE: Do not extend this cable length.

3. Terminals 7, 8, and 9 provide the Web Break Relay

contact signal. Wire as appropriate for Normally

Open (N.O.) or Normally Closed (N.C.) logic (See

Figure 3).

4. Terminals 10, 11, and 12 provide the double sheet-

feed (two sheets stacked on top of each other)

contact signal for sheet-fed machines or the splice

contact signal for web-fed machines. Make electrical

connections as appropriate for N.O. or N.C. logic

(See Figure 3).

5. A relay may be connected to Terminals 13 and 14

to prevent triggering of either the Web Break or

Double Sheet Feed/Web Splice condition. The relay

must be a normally open type which closes when

triggering is to be prevented.

This Lock Out Relay is normally used to prevent

false triggering when the web or sheets stop moving

as the machine is stopped. As the web or sheets

stop moving they often change position (sag, relax

tension, etc.) which causes false triggering.

6. A remote button can be used to reset the system

after a double feed or splice signal, when the

machine is in manual reset mode. If this option is

used, a customer supplied N.O. momentary contact

remote Output Reset switch must be connected to

Terminals 15 and 16 (See Figure 3).

7. Connect the Sensor Receiver 16 ft. [5 m] cable to

Terminals 17, 18, 19, and 20 (See Figure 3).

NOTE: Do not extend this cable length.

INSTALLATION

(continued...)

ELECTRICAL CONNECTIONS