Cleaning should be carried out as needed. There is a big difference depending on the construction setup, adjustments and wood pellet

quality on how often maintenance should be performed. The maintenance table below is only an indication of the type of maintenance

required and applies only for RTB Phoenix systems!

Turn off the burner in connection with cleaning.

Turn off the controller and allow to cool for approx. 5 min. Once the burner is completely turned off, it is ready for cleaning. Unplug the

burner, remove the shield, drop shaft and remove the burner from the boiler so work can be easily performed.

The ash can

Never throw warm ashes in the trash bin, but let it cool off in a metal bucket. Warm ashes can burn if it gets air (02)

Remember to mount the ash bin correctly after emptying it, otherwise smoke can leak out the back!

Burner head.

Remove any ash or cinders from the grate. Remove any pellet remnants under the burner grate.

Ensure that there is nothing lodged in the fan and that it can rotate freely.

O2 Sensor recalibration

Remove O2 sensor head from exhaust mount found on top of the boiler adjacent to the exhaust fan.

Make sure that the O2 sensor is warm and has had power for at least 15 minutes.

Go to BOILER/OXYGEN/START OXYGEN CALIBRATION/START. The sensor will then begin calibrating.

Hopper.

Since pellets naturally contain dust, you should once in a while empty the hopper completely. The more dust that is present in the hopper,

the less pellets the auger will dispense, and the more unstable the dosing. The boiler will go out of adjustment with greater risk of downtime.

How often one should empty the hopper depends greatly on the design and quality of the pellets you use.

Start-Up after cleaning.

Reassemble the system and turn on the controller, the burner will start up automatically.

SERVICE MAINTENANCE

!

!

When

needed

7 days

14 days

30 days

½ annually

Annually

RTB Phoenix

X

X

X

Clean cinders out of the burner head

X

X

Clean under the combustion grate for dust and cinders

X

Clean O2 sensor of dust

X

Clean burner fan from dust

X

X

X

Clean heat exchanger and smoke pipes

X

X

Empty ash drawer, typically every 1000- 3000 kgs

consumed.

X

Check gasket/replace worn gaskets

Check air flow and under pressure sensors/replace

where necessary

X

Recalibrate O2 sensor

X

Filling the hopper

X

Chimney sweeper

23

Содержание RTB PHOENIX v16.0

Страница 1: ...NBE TR PILLESYSTE M RTB ready to burn UK V16 UK UK...

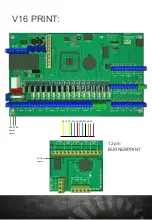

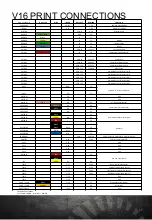

Страница 16: ...V16 PRINT 12 pin BURNERPRINT 10 11 12 13 14 18 50 69 37 38 39 100 230 V power supply Air flow sensor 16...

Страница 28: ...Submenus can be found when accessing a main menu Select to retrieve parameter help text 28...

Страница 33: ...33...

Страница 35: ...WIRING DIAGRAM 35...

Страница 44: ......