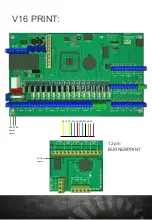

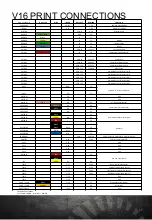

V16 PRINT CONNECTIONS

Main Print Board

12 pin cable

WIRE

INPUTS

OUTPUTS

NUMBER

FUNCTION

100V-240V

PE-N-L

1-2-3

100-240 Volt 50-60Hz

THERM

C-C2

7-8-9

Safety Thermostat

MOTOR

PE-N-L1

4-5-6

External Auger

BURNER

Green/Yelllow

GND

10

BURNER

WHITE

N

11

BURNER

YELLOW

L2

12

Blower

BURNER

GREEN

L3

13

Internal auger

BURNER

BLUE

L4

14

Igniter

EXTRA 1

PE-N-L5

15-16-17

Circulation Pump

EXTRA 1

RED

L6

18

Compressor Cleaning Burner

EXTRA 2

PE-N-L7

19-20-21

Ash Auger

EXTRA 2

PE-N-L8

19-20-22

Compressor

EXTRA 3

PE-N-L9

23-24-25

Compressor Boiler Valve 1

EXTRA 3

PE-N-L10

23-24-26

Compressor Boiler Valve 2

EXTRA 4

PE-N-L11

27-28-29

Exhaust Fan

EXTRA 4

PE-N-L12

Available Output for Accessories.

EXTRA 4

PE-N-L13

Available Output for Accessories.

EXTRA 5

PE-N-L14

Available Output for Accessories.

EXTRA 5

PE-N-L15

Available Output for Accessories.

EXTRA 5

PE-N-L16

Available Output for Accessories.

BUS 1

GRD

70

Available for Extension Module*

BUS 1

RX

71

BUS 1

TX

72

AIRFLOW

3V

Free

AIRFLOW

TX

Free

AIRFLOW

PINK

RX

50

Air Flow Sensor Burner

PRESSURE

BROWN

3V

52

Compressor Pressure Sensor

PRESSURE

BLACK

SIG

53

PRESSURE

0V

54

DISTANCE

BLACK

-

57

Lazer Distance Sensor for Hopper

DISTANCE

YELLOW

SIG

56

DISTANCE

RED

+

55

O2 SENSOR

BLACK

Black

69

O2 Sensor

O2 SENSOR

BLACK

Black

70

O2 SENSOR

WHITE

Gray

71

O2 SENSOR

BLUE

Blue

72

POWER OUT

PE-N-L

66-67-68

Power Supply to Ext Module/ DHW Priority Kit

CONTACT

K-K1

67-68

External Contact ON/OFF*

PULS

P-P1

Free

PULS

P-P2

Free

PULS

P-P3

Free

PULS

P-P4

Free

DISTANCE

RED

+

55

Ash Can Level Sensor

DISTANCE

BLACK

-

57

BP

YELLOW

BP

69

TEMP.

T- T1

41-40

Boiler Temperatue Sensor

TEMP.

T – T2

41-42

Chimney Temperature Sensor

TEMP.

T – T3

44-43

Free/ Return Temperature Sensor*

TEMP.

T – T4

44-45

Free/DHW Temperature Sensor *

TEMP.

T – T5

Free

TEMP.

T – T6

Free

SHAFT. / TEMP

BLACK

T – T9

37

Drop Shaft Sensor Burner

SHAFT. / TEMP

ORANGE

T

38

Motorprint

SHAFT/ TEMP

T-T10

39

Free

*REQUIRES ACCESSORY

PE= YELLOW/GREEN N= BLUE L = BROWN

17

Содержание RTB PHOENIX v16.0

Страница 1: ...NBE TR PILLESYSTE M RTB ready to burn UK V16 UK UK...

Страница 16: ...V16 PRINT 12 pin BURNERPRINT 10 11 12 13 14 18 50 69 37 38 39 100 230 V power supply Air flow sensor 16...

Страница 28: ...Submenus can be found when accessing a main menu Select to retrieve parameter help text 28...

Страница 33: ...33...

Страница 35: ...WIRING DIAGRAM 35...

Страница 44: ......