30

CLEAN WASTE PUMP-OUT PUMP:

Build-up of fine silt inside the optional Waste Pump can clog the pump even if the pump is not used, so this

maintenance procedure should be performed regardless of whether the Waste Pump has been used.

•

After cleaning out the recovery tank, remove the cap and

connect the Pump-Out hose to the Waste Pump outlet

fitting on the back of the machine; run the hose to a drain.

•

Open the drain valve and use a hose to rinse off the Pump-

Out pump and Float Switch.

•

Close the drain valve and fill the recovery tank

approximately 1/2 full with clean water.

•

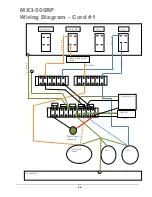

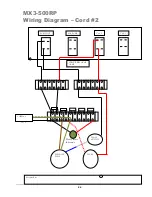

With Cord #2 plugged in, turn the Waste Pump switch to

the ON position. Lift up and hold the float switch to

activate the pump.

•

Let the pump run until it pumps the level down to the point

below close to the bottom of the pump.

•

Unplug the cord and turn the Waste Pump switch OFF.

•

Open the drain valve and drain out the remaining water.

•

Close the drain valve, replace the recovery tank lid, and dispose of the dirty water and debris.

FLUSH SOLUTION TANK AND PUMP:

•

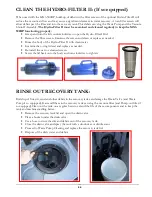

Pour two or three gallons of clean water into the solution tank.

•

With Cords #1 & #2 plugged in, connect a solution hose to the

solution outlet female quick connect. The other end of the hose

should have an open quick connect or no quick connect to allow

full flow out of the hose.

•

Direct the open end of the hose into the recovery tank vacuum

barb.

•

Turn one or both of the vacuums ON and turn the solution pump

ON.

•

Let the pump run until most of the water has been pumped out of

the solution tank.

Do not let the pump run dry. Turn the pump

OFF before the water gets to the bottom of the tank.

•

Turn the vacuums OFF and disconnect the solution hose.

•

Place a bucket under the drain valve; open the drain valve to drain the water out of the recovery tank.

•

Close the drain valve and dispose of the water.

If there is a heavy chemical build-up in the machine, hoses, or tools, a mild acid can be added to the rinse

water in the previous procedure (REFER TO PHOTOS ON FOLLOWING PAGE.)

•

After the pump has been primed, turn the solution pump switch OFF and turn the vacuums OFF.

•

Connect the HP solution hose and tools.

•

Turn the solution pump ON and direct the tool spray into a bucket. Let the pump run until most of

the water has been pumped out of the solution tank.

Do not let the pump run dry. Turn the pump

OFF before the water gets to the bottom of the tank.

•

Disconnect the solution hose and tool.

Pour 2 or 3 gallons of clean

water into Solution Tank

Содержание MX3-500RP

Страница 1: ...1 LMANN14 Revised 06 04 2014 Nautilus MX3 500RP Operating Manual...

Страница 38: ...38 OPTIONAL AUTO FILL FLOAT VALVE ASSEMBLY NM5740...

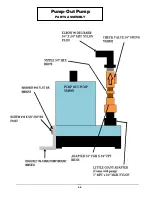

Страница 40: ...40 Pump Out Pump PARTS ASSEMBLY...

Страница 41: ...41 1 2 3 5 4 4 6 7 8 9 10 11 12 3 8 9 8 9 8 9 39 2...

Страница 45: ...45 48 49 49 47 47 47A 47 47A 47 47A 47A 51 51 37 9 54 64 9 54 64 9 54 64 52 VACUUM MOUNTS CONNECTIONS...

Страница 48: ...48 2 39 1 72 73 73 67 9 30 31 82 83 2 83 82 84 INSIDE SOLUTION TANK BOTTOM VIEW SOLUTION TANK...

Страница 50: ...50 92 91 95 94 112 13 14 14A 104 105 1 39 PUMP OUT CONNECTIONS...