9

WS-415-63 / 11.24.98

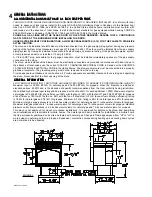

VENTING SPECIFICS

FOR SAFE AND PROPER OPERA

FOR SAFE AND PROPER OPERA

FOR SAFE AND PROPER OPERA

FOR SAFE AND PROPER OPERA

FOR SAFE AND PROPER OPERATION OF THE STOVE, FOLLOW THE VENTING INSTRUCTIONS EXACTL

TION OF THE STOVE, FOLLOW THE VENTING INSTRUCTIONS EXACTL

TION OF THE STOVE, FOLLOW THE VENTING INSTRUCTIONS EXACTL

TION OF THE STOVE, FOLLOW THE VENTING INSTRUCTIONS EXACTL

TION OF THE STOVE, FOLLOW THE VENTING INSTRUCTIONS EXACTLY

YY

YY.....

ALL HORIZONT

ALL HORIZONT

ALL HORIZONT

ALL HORIZONT

ALL HORIZONTAL RUNS MUST HA

AL RUNS MUST HA

AL RUNS MUST HA

AL RUNS MUST HA

AL RUNS MUST HAVE A MINIMUM

VE A MINIMUM

VE A MINIMUM

VE A MINIMUM

VE A MINIMUM 1 INCH

1 INCH

1 INCH

1 INCH

1 INCH RISE PER FOOT

RISE PER FOOT

RISE PER FOOT

RISE PER FOOT

RISE PER FOOT.....

HORIZONT

HORIZONT

HORIZONT

HORIZONT

HORIZONTAL VENTING INST

AL VENTING INST

AL VENTING INST

AL VENTING INST

AL VENTING INSTALLA

ALLA

ALLA

ALLA

ALLATION

TION

TION

TION

TION

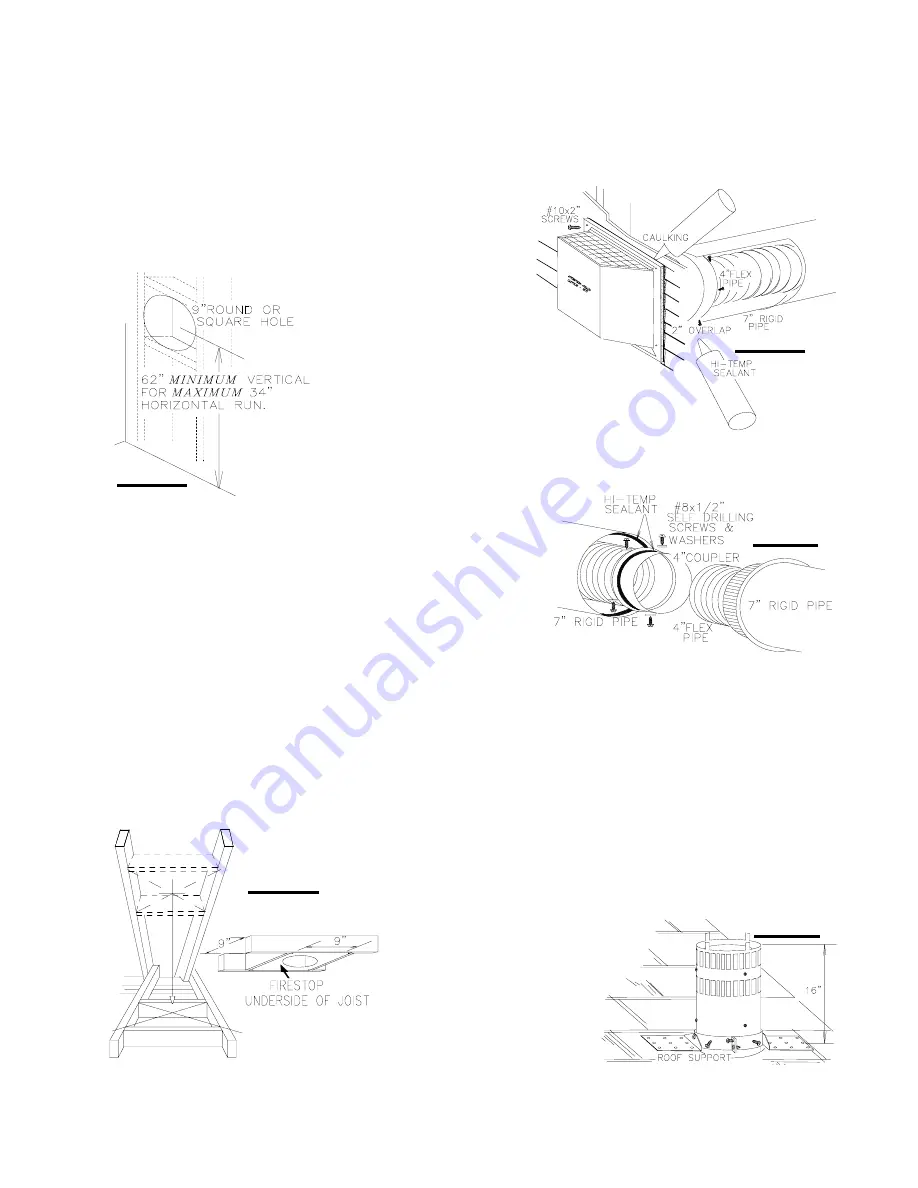

This application occurs when venting through an exterior wall.

FIGURES 2, 3, & 10

.

Having determined the air terminal location:

1.

Cut or frame a hole in the exte-

rior wall with a round or a square

opening of a minimum 9".

THE

THE

THE

THE

THE

STOVE PIPE MUST RISE 1" PER

STOVE PIPE MUST RISE 1" PER

STOVE PIPE MUST RISE 1" PER

STOVE PIPE MUST RISE 1" PER

STOVE PIPE MUST RISE 1" PER

FOOT OF RUN.

FOOT OF RUN.

FOOT OF RUN.

FOOT OF RUN.

FOOT OF RUN.

2.

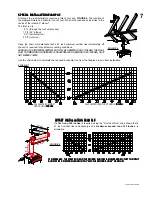

Stretch the 4" diameter aluminum flexible

liner to the required length taking into account the

additional length needed for the finished wall surface.

SP

SP

SP

SP

SPACERS ARE A

ACERS ARE A

ACERS ARE A

ACERS ARE A

ACERS ARE ATT

TT

TT

TT

TTACHED TO THE 4" INNER FLEX LINER

ACHED TO THE 4" INNER FLEX LINER

ACHED TO THE 4" INNER FLEX LINER

ACHED TO THE 4" INNER FLEX LINER

ACHED TO THE 4" INNER FLEX LINER

AAAAAT PREDETERMINED INTERV

T PREDETERMINED INTERV

T PREDETERMINED INTERV

T PREDETERMINED INTERV

T PREDETERMINED INTERVALS TO MAINT

ALS TO MAINT

ALS TO MAINT

ALS TO MAINT

ALS TO MAINTAIN A 1-1/4" AIR

AIN A 1-1/4" AIR

AIN A 1-1/4" AIR

AIN A 1-1/4" AIR

AIN A 1-1/4" AIR

GAP TO THE 7" OUTER STOVE PIPE. THESE SPACERS MUST NOT BE REMOVED.

GAP TO THE 7" OUTER STOVE PIPE. THESE SPACERS MUST NOT BE REMOVED.

GAP TO THE 7" OUTER STOVE PIPE. THESE SPACERS MUST NOT BE REMOVED.

GAP TO THE 7" OUTER STOVE PIPE. THESE SPACERS MUST NOT BE REMOVED.

GAP TO THE 7" OUTER STOVE PIPE. THESE SPACERS MUST NOT BE REMOVED.

Slip

a 4" diameter length of aluminum flexible liner a minimum of 2" over the inner sleeve of the air

terminal. Secure to the sleeve using 3 screws. Seal the joint and screw heads using the high

temperature sealant provided.

FIGURE 12.

3.

Slip the first section of 7" diameter stove pipe a minimum of 2" over

the outer sleeve of the air terminal

.

Secure to the sleeve using 3 screws.

Seal the joint and screw heads using high temperature sealant.

4.

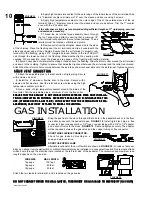

Install the firestop / wall plate to the finished interior wall, maintain-

ing a 1" clearance to combustibles.

Insert the liners through the firestop.

Holding the air terminal (lettering in an upright, readable position), se-

cure to the exterior wall. Make weather tight by sealing with caulking (not

supplied).

FIGURE 10

.

THE AIR TERMINAL MOUNTING PLA

THE AIR TERMINAL MOUNTING PLA

THE AIR TERMINAL MOUNTING PLA

THE AIR TERMINAL MOUNTING PLA

THE AIR TERMINAL MOUNTING PLATE MUST

TE MUST

TE MUST

TE MUST

TE MUST

NOT BE RECESSED INTO THE EXTERIOR WALL OR SIDING.

NOT BE RECESSED INTO THE EXTERIOR WALL OR SIDING.

NOT BE RECESSED INTO THE EXTERIOR WALL OR SIDING.

NOT BE RECESSED INTO THE EXTERIOR WALL OR SIDING.

NOT BE RECESSED INTO THE EXTERIOR WALL OR SIDING.

5.

If more than one length of liner needs to be used to reach the stove, couple them together as illustrated in

Figure 12

.

Seal the joints using the same procedure as described in Item 3.

The vent system must be supported approximately every 10 feet along a horizontal run. Use supports or equivalent non-

combustible strapping to maintain the 1" clearance from combustibles.

A firestop/wall plate must be placed on the inside of each framed opening in a wall that the stove pipe passes through.

VER

VER

VER

VER

VERTICAL VENTING INST

TICAL VENTING INST

TICAL VENTING INST

TICAL VENTING INST

TICAL VENTING INSTALLA

ALLA

ALLA

ALLA

ALLATION

TION

TION

TION

TION

THIS APPLICATION OCCURS WHEN VENTING THROUGH A ROOF

FIGURE 4

. Installation kits for various roof pitches

are available from your Napoleon dealer. See page 5 to order the specific kit required.

1.

Move the stove into position. Try to center the exhaust of the stove midway between two joists to prevent having to cut

them. Use a plumb bob to line up the center of the opening.

2.

Cut and frame a 9" opening in the roof to provide a 1" clearance

between the stove pipe and any combustible material. DO NOT FILL THIS

SPACE WITH ANY TYPE OF MATERIAL. Nail headers between the joists

for extra support. A firestop/wall plate must be placed on the bottom of

each framed opening in a floor or ceiling that the stove pipe passes

through.

3.

Hold a plumb bob from the un-

derside of the roof to determine

where the opening in the roof

should be. Cut and frame the roof

opening to maintain proper 1"

clearances.

4.

Fasten the roof support to the

roof using the screws provided. The

roof support is optional. In this case the venting is to be adequately supported using either an alternate method suitable

to the authority having jurisdiction or the optional roof support.

FIGURE 11

FIGURE 12

FIGURE 13

FIGURE 10

FIGURE 14