M1.3.BT200-BT200M.NLFREN 13112018

9

NL

Elke dag:

•

Reinig de machine eenmaal per dag na gebruik.

Eenmaal per week:

•

Reinig het vuil op de draaitafel met dieselolie en smeer de glijbanen van de

spanklauwen.

Eenmaal per maand:

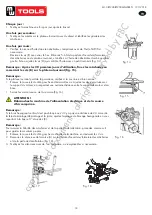

• Controleer het oliepeil in de olienevelaar. Vul bij indien nodig met SAE30 olie.

Draai de schroef (E) met een inbussleutel. Druk 5-6 maal op de voetpedaal van de

draaitafel of van de spanklauwen, en controleer of de olie in de olienevelaar druppelt.

Anders, regel de schroef (D), die de olie controleert, met een kleine schroevendraaier

(afb. 14).

Let op: Na de eerste 20 dagen gebruik, maak de spanklauwen vast door de

schroeven (B) op de draaitafel aan te draaien (afb. 15).

Let op:

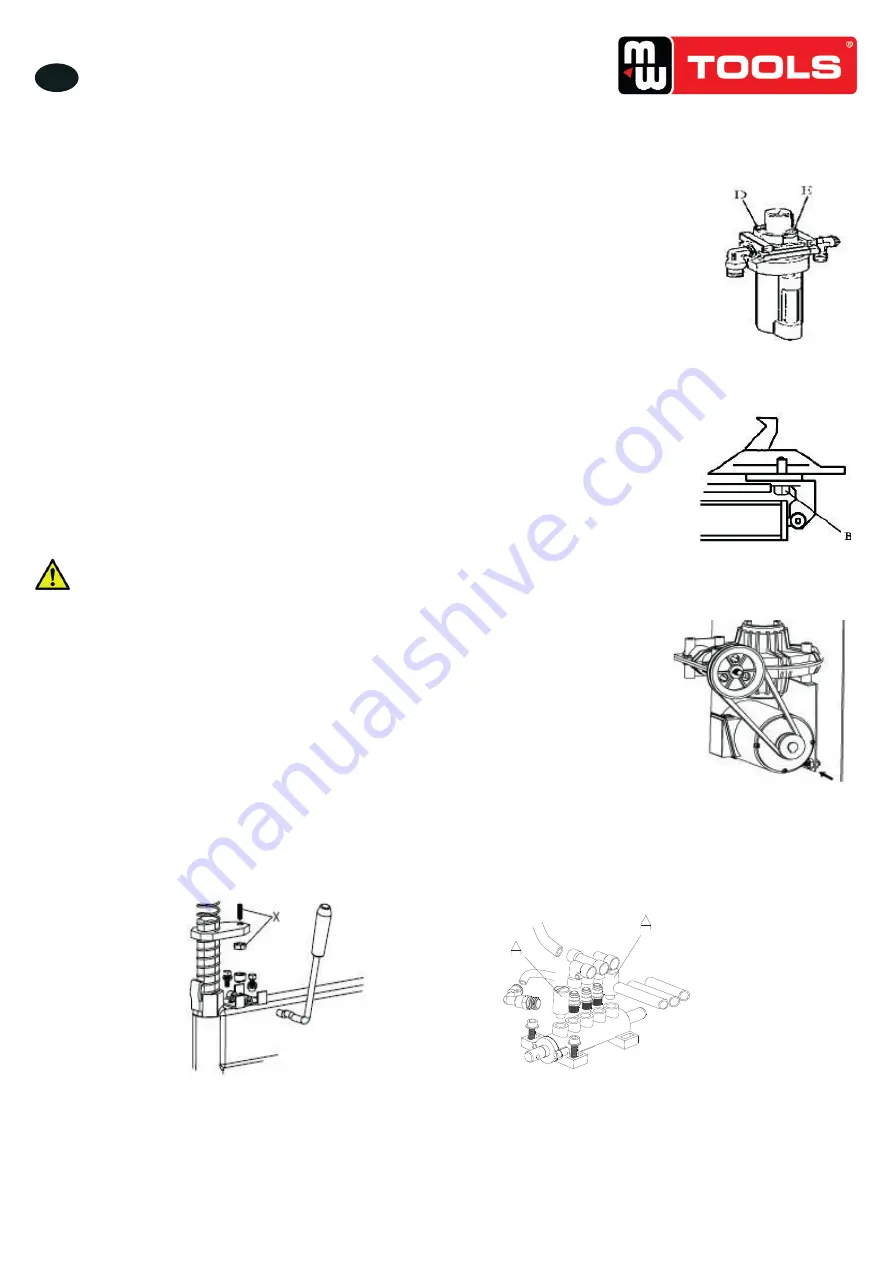

Als de draaitafel kracht verliest, controleer dat de riem goed gespannen is:

• Verwijder het deksel aan de linkerkant door de schroeven los te draaien. Stel de twee

schroeven aan de motorsteun in, door een afstand te laten tussen de motorsteun en de

basis.

• Draai de spanschroeven van de riem vast (afb. 16).

AANDACHT!

Ontkoppel de machine van de stroomtoevoer en van de persluchtbron.

Let op:

Als de verticale zeshoekige arm niet vergrendeld wordt, of als er geen 2-3 mm afstand is

tussen de demontage-/montagekop en de velg is, stel de zeshoekige slotplaat in zoals in

afbeelding 17 getoond, en regel de (X).

Let op:

Voor de betrouwbaarheid van de spanklauwen en van de hielbreker, ga als volgt te werk om

hun ventielen schoon te houden:

1.

Verwijder het deksel aan de linkerkant van de behuizing, door beide schroeven los te

draaien.

2. Draai de dempers van het ventiel (A) op de voetpedaal voor het openen/sluiten van de

spanklauwen en van de hielbreker (afb. 18).

3.

Reinig de dempers met perslucht, of vervang deze indien nodig.

.1211 . V201301

- 7

–

12. Moving machine:

Please use forklift to move the machine. Disconnect the tyre changer from the electricity power supply and

pneumatic power supply, lift the base board and insert the feet of forklift. Then mount the tyre changer machine to a

new position and fix it tightly.

Note: the place chosen for fixing the tyre changer must meet the safety regulation

.

13. Maintenance:

Caution: only the professional persons can do the maintenance. To prolong the machine's life, maintain the

machine timely according to the manual. Otherwise, it will impact the reliability of the machine or even cause

injury to operator and others nearby

.

Caution: before performing any maintenance, disconnect the tyre changer from the

electric power supply and pneumatic power supply, and tread the Jaws open and close

Pedal or Turntable Rotation Pedal for 3~4 times to evacuate all compressed air from the

machine. Damaged parts must be replaced by professional persons with the spare parts

provided by manufacturer.

- Clean the machine once every day after work. Clean the dirt on the turntable with diesel oil

once per week and lubricate the slides and clamps.

- Following maintenance must be done at least once per month:

Check oil level in Oil Fog Maker, please be filled with SAE30# oil if need.

Unscrew with hex wrench (E). Based on connection of compressed air, first to

tread Jaws open and close Pedal or Turntable Rotation Pedal 5-6 times, and

then check whether oil in Oil Fog Maker drops down a drip of oil. For

continuous operation, tread twice every time, drop down a drip of oil,

otherwise adjust the screw (D) that controlled oil enter with minus screwdriver.

(Fig 14)

Note: After the first 20 days of use, retighten the jaws with tightening screws (B) on the Turntable (Fig 15)

Note: in the event of turntable lose power, check to see if the belt is tight as follow steps:

Remove the left side cover by unscrewing the screws; adjust two screws located on the motor support, keep a

suitable distance between motor support and motor base; tight the screws for the belt tension

.(

Fig 16

)

Caution: please disconnect the machine from electric power supply and pneumatic power supply.

Note: If Hexagonal Vertical Arm not be locked or not meet the requirement that 2-3mm from the bottom of

Mounting/demounting head to rim, please adjust Hexagonal Locking Plate, refer to Fig 17 and adjust the (X)

.

Fig 14

Fig 15

Afb. 14

.1211 . V201301

- 7

–

12. Moving machine:

Please use forklift to move the machine. Disconnect the tyre changer from the electricity power supply and

pneumatic power supply, lift the base board and insert the feet of forklift. Then mount the tyre changer machine to a

new position and fix it tightly.

Note: the place chosen for fixing the tyre changer must meet the safety regulation

.

13. Maintenance:

Caution: only the professional persons can do the maintenance. To prolong the machine's life, maintain the

machine timely according to the manual. Otherwise, it will impact the reliability of the machine or even cause

injury to operator and others nearby

.

Caution: before performing any maintenance, disconnect the tyre changer from the

electric power supply and pneumatic power supply, and tread the Jaws open and close

Pedal or Turntable Rotation Pedal for 3~4 times to evacuate all compressed air from the

machine. Damaged parts must be replaced by professional persons with the spare parts

provided by manufacturer.

- Clean the machine once every day after work. Clean the dirt on the turntable with diesel oil

once per week and lubricate the slides and clamps.

- Following maintenance must be done at least once per month:

Check oil level in Oil Fog Maker, please be filled with SAE30# oil if need.

Unscrew with hex wrench (E). Based on connection of compressed air, first to

tread Jaws open and close Pedal or Turntable Rotation Pedal 5-6 times, and

then check whether oil in Oil Fog Maker drops down a drip of oil. For

continuous operation, tread twice every time, drop down a drip of oil,

otherwise adjust the screw (D) that controlled oil enter with minus screwdriver.

(Fig 14)

Note: After the first 20 days of use, retighten the jaws with tightening screws (B) on the Turntable (Fig 15)

Note: in the event of turntable lose power, check to see if the belt is tight as follow steps:

Remove the left side cover by unscrewing the screws; adjust two screws located on the motor support, keep a

suitable distance between motor support and motor base; tight the screws for the belt tension

.(

Fig 16

)

Caution: please disconnect the machine from electric power supply and pneumatic power supply.

Note: If Hexagonal Vertical Arm not be locked or not meet the requirement that 2-3mm from the bottom of

Mounting/demounting head to rim, please adjust Hexagonal Locking Plate, refer to Fig 17 and adjust the (X)

.

Fig 14

Fig 15

Afb. 15

.1211 . V201301

- 8 -

Note: In order to achieve the reliability of jaws and Bead Breaker shovel, operate as follows to keep their valves

clean

:

1. Remove the left side cover of the machine body by unscrewing the two screws;

2. Loosen the valve Muffler (A) which belong to Jaws open and close Pedal and Bead Breaker Pedal;

(Fig 18)

3. Clean the mufflers with compressed air, please replace it referring to the spare parts list if it is damaged.

(Fig 18)

Fig 16 Fig 17

14. Trouble shooting table:

Problem

Reason

Solution

The turntable rotate just in one

direction or ca

n’t rotate

.

Reverse Switch broken

Replace the Reverse Switch

Belt broken

Replace the belt

The

Motor’s malfunction

Check the motor cable or terminal

block wire;

Replace the motor if it was

broken.

Demount or fix the wheel, the

turntable can’t lock

(spin with

wheel);

The jaws delay to open/close;

The turntable locks the rim

incorrectly.

Leakage of Air network

Check all the parts on the air

network.

The clamping c

ylinder can’t work

.

Replace the cylinder piston.

Worn jaws

Replace the jaws.

Broken washers of the chuck cylinder

Replace it.

The mounting/demounting head

always touch the rim during

operation.

The locking plate incorrectly adjust or

unqualified.

Replace or adjust it.

Screws on the chuck loose; the

Hexagonal Vertical Arm

can’t be

locked by Locking Plate

Tighten the screws; replace the

Locking Plate.

The Bead Breaker Pedal and

Jaw open and close Pedal

can’t

turn back to the original

position.

Pedal spring broken

Replace it.

The Bead Breaker shovel

operates difficultly.

Jammed silencer

Clean it or replace it.

The washer on the Bead Breaker

cylinder is broken.

Replace it.

Fig 18

.1211 . V201301

- 8 -

Note: In order to achieve the reliability of jaws and Bead Breaker shovel, operate as follows to keep their valves

clean

:

1. Remove the left side cover of the machine body by unscrewing the two screws;

2. Loosen the valve Muffler (A) which belong to Jaws open and close Pedal and Bead Breaker Pedal;

(Fig 18)

3. Clean the mufflers with compressed air, please replace it referring to the spare parts list if it is damaged.

(Fig 18)

Fig 16 Fig 17

14. Trouble shooting table:

Problem

Reason

Solution

The turntable rotate just in one

direction or ca

n’t rotate

.

Reverse Switch broken

Replace the Reverse Switch

Belt broken

Replace the belt

The

Motor’s malfunction

Check the motor cable or terminal

block wire;

Replace the motor if it was

broken.

Demount or fix the wheel, the

turntable can’t lock

(spin with

wheel);

The jaws delay to open/close;

The turntable locks the rim

incorrectly.

Leakage of Air network

Check all the parts on the air

network.

The clamping c

ylinder can’t work

.

Replace the cylinder piston.

Worn jaws

Replace the jaws.

Broken washers of the chuck cylinder

Replace it.

The mounting/demounting head

always touch the rim during

operation.

The locking plate incorrectly adjust or

unqualified.

Replace or adjust it.

Screws on the chuck loose; the

Hexagonal Vertical Arm

can’t be

locked by Locking Plate

Tighten the screws; replace the

Locking Plate.

The Bead Breaker Pedal and

Jaw open and close Pedal

can’t

turn back to the original

position.

Pedal spring broken

Replace it.

The Bead Breaker shovel

operates difficultly.

Jammed silencer

Clean it or replace it.

The washer on the Bead Breaker

cylinder is broken.

Replace it.

Fig 18

.1211 . V201301

- 8 -

Note: In order to achieve the reliability of jaws and Bead Breaker shovel, operate as follows to keep their valves

clean

:

1. Remove the left side cover of the machine body by unscrewing the two screws;

2. Loosen the valve Muffler (A) which belong to Jaws open and close Pedal and Bead Breaker Pedal;

(Fig 18)

3. Clean the mufflers with compressed air, please replace it referring to the spare parts list if it is damaged.

(Fig 18)

Fig 16 Fig 17

14. Trouble shooting table:

Problem

Reason

Solution

The turntable rotate just in one

direction or ca

n’t rotate

.

Reverse Switch broken

Replace the Reverse Switch

Belt broken

Replace the belt

The

Motor’s malfunction

Check the motor cable or terminal

block wire;

Replace the motor if it was

broken.

Demount or fix the wheel, the

turntable can’t lock

(spin with

wheel);

The jaws delay to open/close;

The turntable locks the rim

incorrectly.

Leakage of Air network

Check all the parts on the air

network.

The clamping c

ylinder can’t work

.

Replace the cylinder piston.

Worn jaws

Replace the jaws.

Broken washers of the chuck cylinder

Replace it.

The mounting/demounting head

always touch the rim during

operation.

The locking plate incorrectly adjust or

unqualified.

Replace or adjust it.

Screws on the chuck loose; the

Hexagonal Vertical Arm

can’t be

locked by Locking Plate

Tighten the screws; replace the

Locking Plate.

The Bead Breaker Pedal and

Jaw open and close Pedal

can’t

turn back to the original

position.

Pedal spring broken

Replace it.

The Bead Breaker shovel

operates difficultly.

Jammed silencer

Clean it or replace it.

The washer on the Bead Breaker

cylinder is broken.

Replace it.

Fig 18

Afb. 16

Afb. 17

Afb. 18

copyrighted

document

- all

rights

reserved

by

FBC