13

FR

M1.3.BT200-BT200M.NLFREN 13112018

.1211 . V201301

- 2 -

3. Technical data

External locking rim dimensions

10~21

"

Internal locking rim dimensions

12~24

"

Max. Wheel diameter

1040mm(41

"

)

Max. Wheel width

355mm(14

"

)

Working Pressure

8-10bar

Power supply

110V (1ph)/ 220V (1ph)/ 380V (3ph)

Optional Motor power

0.75/0.55/1.1 kw

Max. Rotating Torque (Turntable)

1078 Nm

Overall Dimension

96*76*93cm

Noise Level

75 Db

Remark

:

Rim dimensions defined at above table are based on the iron wheel rims. Aluminum rims are thicker than the

iron wheel rims, so here above rim dimensions are just for the reference.

Here above machine versions can be equipped with Rapid Tire Inflation Device (client optional device),

IT-suffix version, accessory details can be found at the IT-suffix version exploded drawing.

4. Transport:

When transporting, the machine should be with original package and placed according to the mark on the package.

For the already packaged machine should be handled with a corresponding tonnage forklift for loading and unloading.

The location to insert the fork feet shown as

Fig 1

5. Unpacking & Inspection:

Pull out the nail which is nailed on the plate with tip jaw; unpack the carton and plastic cover. Check and make sure

all parts shown on the spare parts list are included. If any parts are missing or broken, please do not use the machine

and contact the manufacturer or dealer ASAP.

Fig 1 Fig 2 Fig 3

6. Workplace requirements:

Choose workplace in compliance with safety regulations. Connect power supply and air source according to manual

and workplace must have good air condition; in order to make the machine run well, its workplace requires at least

clear space from each wall shown as

Fig 2

. If installing it outdoor, it must be protected by roof against rain and

sunshine.

Warning: the machine with motor must not be operated in explosive atmosphere

.

Fig. 1

.1211 . V201301

- 2 -

3. Technical data

External locking rim dimensions

10~21

"

Internal locking rim dimensions

12~24

"

Max. Wheel diameter

1040mm(41

"

)

Max. Wheel width

355mm(14

"

)

Working Pressure

8-10bar

Power supply

110V (1ph)/ 220V (1ph)/ 380V (3ph)

Optional Motor power

0.75/0.55/1.1 kw

Max. Rotating Torque (Turntable)

1078 Nm

Overall Dimension

96*76*93cm

Noise Level

75 Db

Remark

:

Rim dimensions defined at above table are based on the iron wheel rims. Aluminum rims are thicker than the

iron wheel rims, so here above rim dimensions are just for the reference.

Here above machine versions can be equipped with Rapid Tire Inflation Device (client optional device),

IT-suffix version, accessory details can be found at the IT-suffix version exploded drawing.

4. Transport:

When transporting, the machine should be with original package and placed according to the mark on the package.

For the already packaged machine should be handled with a corresponding tonnage forklift for loading and unloading.

The location to insert the fork feet shown as

Fig 1

5. Unpacking & Inspection:

Pull out the nail which is nailed on the plate with tip jaw; unpack the carton and plastic cover. Check and make sure

all parts shown on the spare parts list are included. If any parts are missing or broken, please do not use the machine

and contact the manufacturer or dealer ASAP.

Fig 1 Fig 2 Fig 3

6. Workplace requirements:

Choose workplace in compliance with safety regulations. Connect power supply and air source according to manual

and workplace must have good air condition; in order to make the machine run well, its workplace requires at least

clear space from each wall shown as

Fig 2

. If installing it outdoor, it must be protected by roof against rain and

sunshine.

Warning: the machine with motor must not be operated in explosive atmosphere

.

Fig. 2

.1211 . V201301

- 2 -

3. Technical data

External locking rim dimensions

10~21

"

Internal locking rim dimensions

12~24

"

Max. Wheel diameter

1040mm(41

"

)

Max. Wheel width

355mm(14

"

)

Working Pressure

8-10bar

Power supply

110V (1ph)/ 220V (1ph)/ 380V (3ph)

Optional Motor power

0.75/0.55/1.1 kw

Max. Rotating Torque (Turntable)

1078 Nm

Overall Dimension

96*76*93cm

Noise Level

75 Db

Remark

:

Rim dimensions defined at above table are based on the iron wheel rims. Aluminum rims are thicker than the

iron wheel rims, so here above rim dimensions are just for the reference.

Here above machine versions can be equipped with Rapid Tire Inflation Device (client optional device),

IT-suffix version, accessory details can be found at the IT-suffix version exploded drawing.

4. Transport:

When transporting, the machine should be with original package and placed according to the mark on the package.

For the already packaged machine should be handled with a corresponding tonnage forklift for loading and unloading.

The location to insert the fork feet shown as

Fig 1

5. Unpacking & Inspection:

Pull out the nail which is nailed on the plate with tip jaw; unpack the carton and plastic cover. Check and make sure

all parts shown on the spare parts list are included. If any parts are missing or broken, please do not use the machine

and contact the manufacturer or dealer ASAP.

Fig 1 Fig 2 Fig 3

6. Workplace requirements:

Choose workplace in compliance with safety regulations. Connect power supply and air source according to manual

and workplace must have good air condition; in order to make the machine run well, its workplace requires at least

clear space from each wall shown as

Fig 2

. If installing it outdoor, it must be protected by roof against rain and

sunshine.

Warning: the machine with motor must not be operated in explosive atmosphere

.

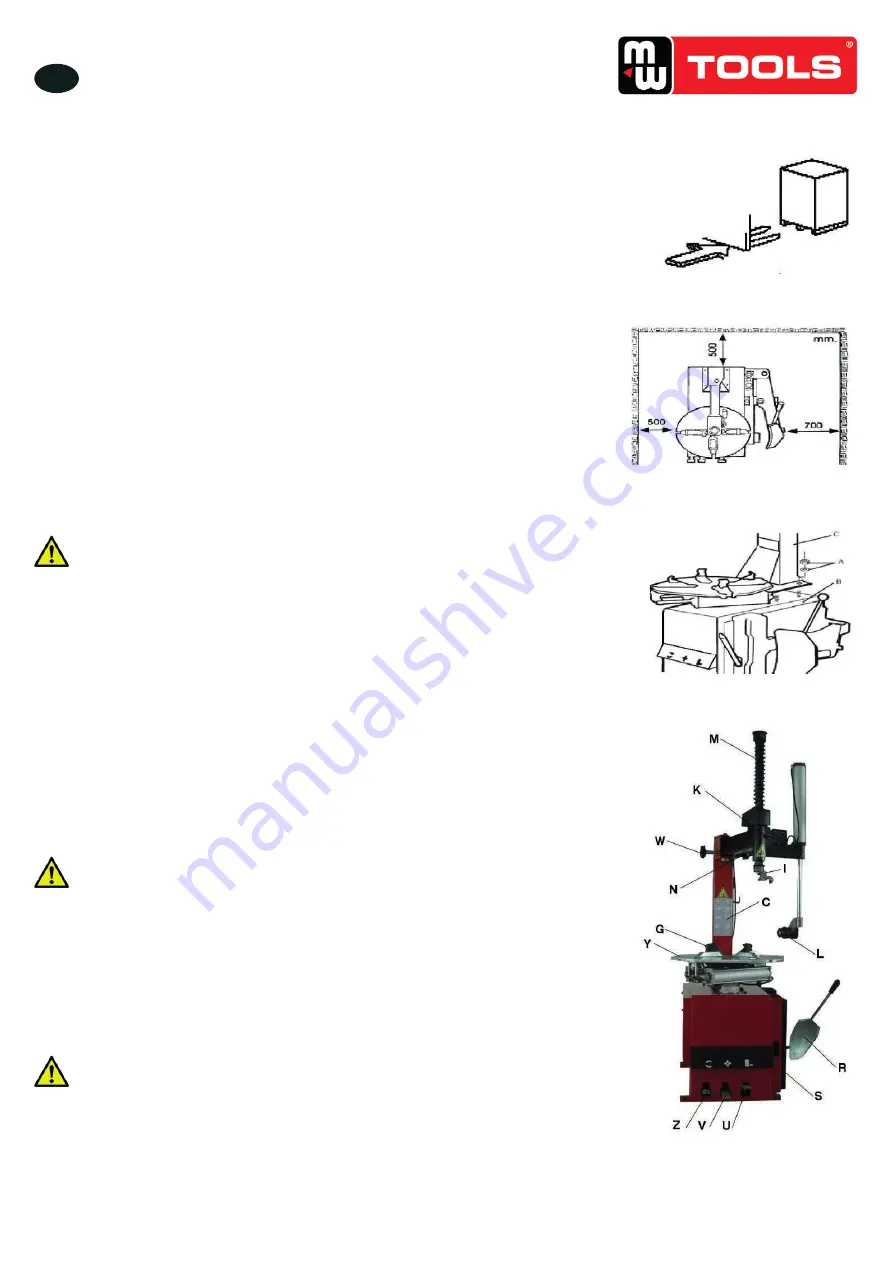

Fig. 3

.1211 . V201301

- 3

–

7. Position and installation:

1. Unscrew the nuts at the bottom, position the machine and calibrate it with the

horizontal rule. Mount the machine with all the screws and to ensure the machine is

stable. Make sure the system is equipped with a good grounding circuit for prevent

electric leakage. And have operation range of ground for skid prevention.

2. Unscrew the nut A on the cabinet body B as shown in

Fig 3

.

Lift the column C; mount it on the machine body B by using the nut A through the

bolt located on the machine body B. If the column becom

e

s loose after a period of

using, tight them immediately. Otherwise the result of damage to the tyre may

happen.

8. Electricity and Pneumatic connections:

Caution: Before installation and connection, check to be sure that the electricity

power supply corresponds to the machine technical data. All the installation of

electric and pneumatic devices must be operated by a professional electrician

.

Connect the compressed air connector which is on the machine right side with

compressed air system. The electric grid that the machine connects to must have

fuses protection device and good outer cover grounding protection. Install the

leakage automatic air switch on the maim power supply, leakage current is set at 30A

Caution: No power plug for this machine, the user should self-connect one power plug no less than 16A as well

as in line with the machine voltage. Or directly connect with the power supply according to the above

requirements

.

9. Adjusting operation:

Turntable Rotation Pedal (Z)

Bead Breaker Pedal (U)

Jaws open and close Pedal (V)

1)

Tread the Turntable Rotation Pedal (Z), Turntable (Y) clockwise rotation; Lift up the Turntable Rotation

Pedal (Z), Turntable (Y) counterclockwise rotation.

2)

Tread Bead Breaker Pedal (U), Bead Breaker shovel (R) close toward inside; release Bead Breaker Pedal (U),

Bead Breaker shovel (R) return to original position.

3)

Tread Jaws open and close Pedal (V), four clamps (G) on the turntable open; tread again, four clamps (G)

close. When the pedal is in the middle position, the four clamps stop moving.

Tyre changer operation is consisted of three parts:

1

)

Breaking the tyre bead

2

)

Demounting the tyre

3

)

Mounting the tyre

Caution: Before any operations, don

’

t wear loose clothing and wear protective hat, gloves, and skid-proof shoes.

Ensure to exhaust the air in the tyre completely, and remove all the wheel weights from the rim.

Fig 4

Fig. 4

4 Transport

Lors du transport, la machine doit être dans son emballage original et placée selon les

marques sur celui-ci. La machine emballée doit être transportée, déplacée et déposée par

un élévateur à fourche d’une capacité suffisante. La figure 1 montre comment placer la

fourche.

5 Déballage et inspection

Avec une tenaille, enlevez le clou se trouvant sur la plaque. Enlevez le carton et le

couvercle en plastique. Comparez le contenu de l’emballage avec la liste de colisage. Si

une pièce est manquante ou endommagée, n’utilisez pas la machine et contactez votre

revendeur immédiatement.

6 Exigences pour le lieu d’installation

Veillez à ce que l’espace de travail soit conforme à la réglementation en matière de

sécurité. Branchez l’alimentation électrique et la source d’air comprimé comme indiqué, et

veillez à ce que l’atelier soit bien aéré. Veillez à prévoir un espace suffisant autour de la

machine, comme illustré en figure 2. Si la machine est installée à l’extérieur, un toit doit la

protéger de la pluie et des rayons du soleil.

ATTENTION !

La machine motorisée ne peut pas être utilisée dans un

environnement explosif.

7 Installation de la machine

1.

Dévissez les écrous dans le bas, placez la machine en vérifiant qu’elle est bien

horizontale. Montez la machine avec toutes les vis et assurez-vous qu’elle est stable.

Assurez-vous que l’installation électrique est munie d’une bonne prise de terre pour

prévenir les fuites électriques. Veillez également à ce que le sol soit antidérapant.

2.

Dévissez l’écrou A sur le châssis B comme illustré en figure 3. Levez la colonne

C. Montez-la sur le châssis B en utilisant l’écrou A et le boulon se trouvant sur le

châssis B. Si la colonne se desserre après une période d’utilisation, resserrez-la

immédiatement. Sinon, le pneu pourrait être endommagé.

8 Branchements électriques et pneumatiques

ATTENTION !

Avant l’installation et le branchement, assurez-vous que

l’installation électrique corresponde aux données techniques de la

machine. Les branchements électriques et pneumatiques doivent

être effectués par un électricien qualifié.

Branchez le raccord d’air comprimé situé sur le côté droit de la machine avec votre

système d’air comprimé. Le boîtier électrique sur lequel vous branchez la machine doit

être équipé d’un disjoncteur et d’une bonne mise à la terre. Installez l’interrupteur de

protection sur l’alimentation principale. Le courant de fuite est de 30 A.

ATTENTION !

Il n’y a pas de fiche d’alimentation sur cette machine. L’utilisateur

doit installer lui-même une fiche d’au moins 16 A, et qui correspond

à la tension de la machine. Il peut également brancher la machine

directement selon les exigences ci-dessus.

copyrighted

document

- all

rights

reserved

by

FBC