M1.2.HB240-HB240M.NLFREN 21112017

7

NL

3�2 Vereisten voor de installatie

•

Maak zeker dat de twee kolommen perfect parallel en verticaal zijn, niet schuin.

• De aansluitingen van de olieslangen en stalen kabels moeten goed vast worden verbonden, om losse kabels en

olielekkages te voorkomen.

• Alle bouten moeten stevig worden aangedraaid.

•

Plaats geen voertuig op de brug tijdens het proefdraaien.

3�3 Installatie

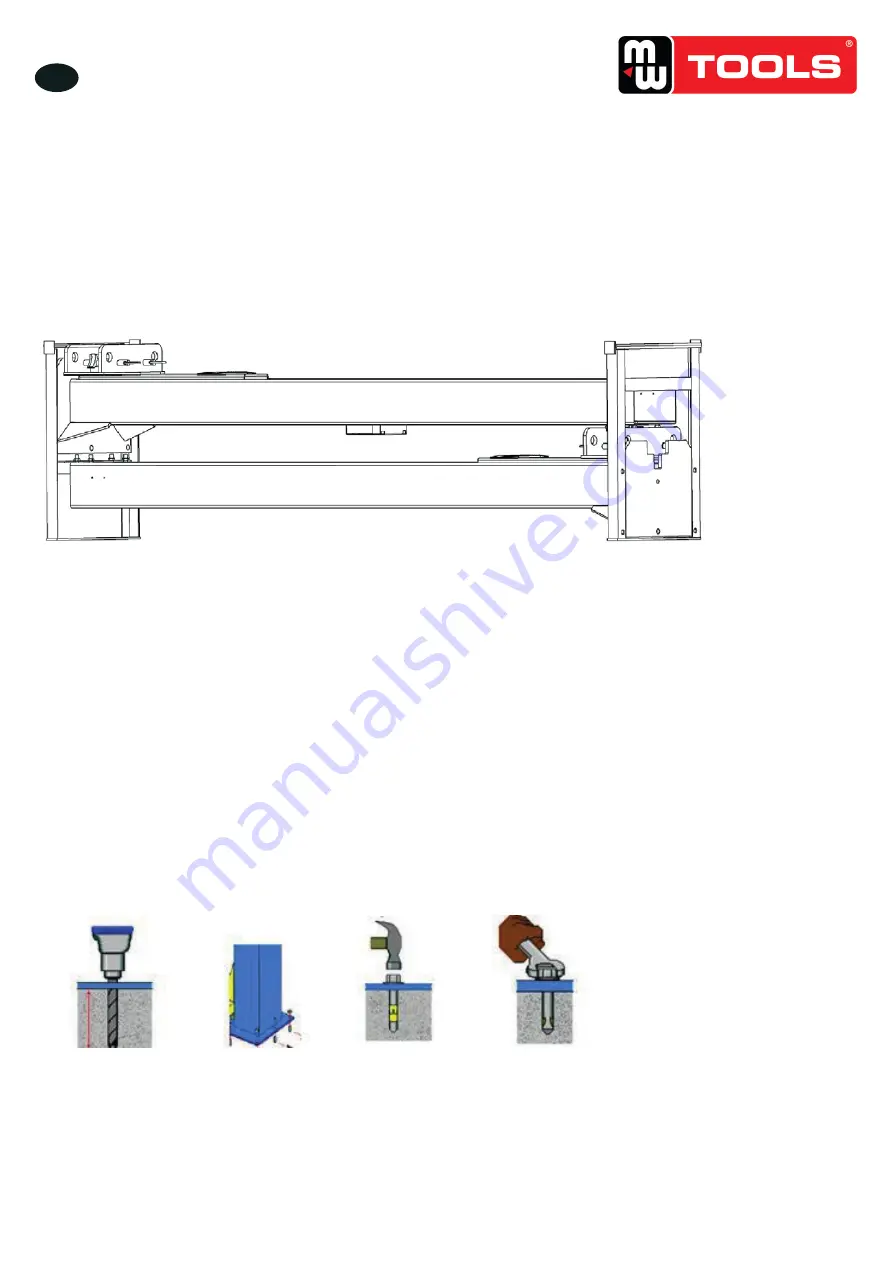

Fig� 3

1�

Verwijder de verpakking, neem de doos met de accessoires en bovenplaat.

2�

Plaats eerst een ondersteuning tussen de twee kolommen of hang een van beide kolommen met een kraan, en verwijder de

bouten op de verpakking.

Aandacht! Laat vooral de kolom niet vallen, want het kan ongevallen veroorzaken en tot schade

aan de kolom of aan de accessoires in de kolom leiden�

3�

Nadat de eerste kolom uitgepakt werd, plaats een ondersteuning onder de tweede kolom en verwijder de bouten op de

verpakking.

4�

Bevestig de verticale positie voor de twee kolommen (zie

hoofdstuk 9

, grondplan).

1. Vouw het pakket uit en beslis op welke kolom de voedingseenheid zal worden gemonteerd.

2. Teken een schets van de basisplaat met krijt op de grond en bepaal de positie van de kolom.

5�

Plaats de kolommen rechtop, eerst deze met de voedingseenheid, daarna de andere.

1. Boor de ankergaten in de grond met de boorhamer voor de expansiebouten. Zorg ervoor om perfect verticaal te boren

(

fig. 3

).

2. Nadat de gaten geboord zijn, verwijder het puin en het stof zorgvuldig, en maak zeker dat de kolommen blijven op de

cirkels eerder met krijt getekend (

fig. 4, 5, 6

).

USER’S GUIDE V1.0 201511

- 6 -

INSTALLATION INSCRUCTIONS

3.1 Preparations before installation

3.1.1 Tools and equipments needed

Appropriate lifting equipment

Anti-abrasion hydraulic oil.

Rotary Hammer Drill with 3/4’’ drill bit.

Chalk and tape measure,

magnetic plump, 8 metersФ15 level pipe.

Sockets and open wrenches, a set of inside hex wrenches, cross and straight screw drivers.

Hammer, 4pounds,

sharp nose pliers,

Ф17,Ф19,Ф22

socket spanners

。

3.1.2 List for parts checking ---Annex 1

(

Packing list

)

Unfold the package and check if any parts missed as per Annex 1. Do not hesitate to contact us in case any parts missed, but if

you do not contact us and insist installing upon the lack of some parts, well as our dealers will not bear any responsibility for this

and will charge for any parts subsequently demanded by the buyer.

3.1.3 Ground conditions

The lift should be fixed on a smooth and solid concrete ground with its strength more than 3000psi, tolerance of flatness less

than 5mm and minimum thickness of 200mm. In addition, newly built concrete ground must undergo more than 28days’ cure

and reinforcement.

3.2 Precautions for installation

3.2.1 Make sure the two posts stand paralleled and are vertical to the ground. No slanting.

3.2.2 Joints of oil hose and steel cable must be firmly connected in order to avoid the looseness of steel cable and leakage of oil

hose.

3.2.3 All bolts should be firmly screwed up.

3.2.4 Do not place any vehicle on the lift in the case of trial running.

3.3 Installation

Step 1: Remove the packaging, take out the carton for accessories and cover plate.

Step 2: Firstly, put something supporting between the two posts or suspend one of the posts by a crane and then remove the

bolts on the package.

Attention

:

Please pay special attention not to let the post fall down for it may cause casualty or bring damages to the accessories

fixed in the post.

Step3: When the first post has been taken away, place something supporter under the second post and then remove the bolts

on the package.

USER’S GUIDE V1.2 201503

- 7 -

Step 4: Fix the standing position for the two posts. (See Annex 3, floor plan)

1. Unfold the package and decide on which post the power unit will be mounted.

2. Draw an outline of the base plate on the ground with chalk and ascertain the position for the post.

Step 5: Erect the posts, power side post first and then the other post.

1.Drill anchor holes for expansion bolts on the ground with an electrical drill. Make sure to drill vertically.

(Fig 3)

2.After holes have been drilled, remove thoroughly the debris and dust in them and ascertain that the posts stay upon the circle

previously drawn by chalk.

(Fig 4,5,6)

Step6: Connect steel cables. (Fig 7)

1. Route and fix according to the following diagram of steel cable connection.

2. Raise carriages on both sides approximately 800mm above the ground. Carriages must be on the same height from the floor.

3. Make sure that the mechanical safety locks in each post are fully engaged before attempting to route cables.

4. After the cable being fixed, adjust and make the cable at both sides be with the same tightness which could be judged by the

sound emitted during lifting process. Make judge and adjustment after trial running.

5. Grease after being fixed. (It is a must.)

Fig 3

Fig 4

Fig 5

Fig 6

Fig� 3

Fig� 4

Fig� 5

Fig� 6

copyrighted

document

- all

rights

reserved

by

FBC