28

=

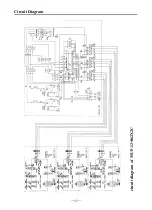

For details about how to use manifold valves, see the

instruction manual for manifold valves.

=

The handle Hi below connect operate during the following

work if it is fully closed.

=

Evacuate every indoor unit for rooms A

B and C.

Air purge and leak test

In the case of gas leakage

Tighten the flare nut connections.

If this tightening does not help stopping the leakage

repair the leak portion (s).remove the gas from the

service port, refill the specified amount from the

cylinder gas.

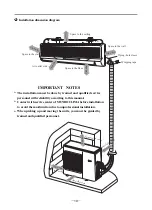

WARNING:

When installing or moving the unit, do not mix

anything other than specified refrigerant (R22) into

the refrigerating cycle.

If air is mixed,it may cause the refrigerating cycle to

get abnormally high temperatre, causing a risk of

burst.

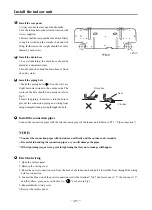

Evacuate the circuit for 15 minutes or more,and make sure

that the compound pressure gage reads-760 mm Hg.

After finishing the evacuation.fully close the handle Lo on

the manifold valve. and then stop the vacuum pump.

Fully open the stop valve (2-way and 3-way valves) by

turning the valve rods to the left until they stop When the

rods contact the stoppers. do not apply force any more.

Tighten the valve rod caps for the stop valves (2-way and

3-way valves).

Leak test

Using soapy water. perform the leak test for both the indoor

and outdoor sides,Make sure no bubbles appear on the

connections. If bubbles appear they indicate gas is leaking

from that point.

If gas is leaking

Tighten the flare nut connection more strongly.

If it has no effect.repair any existing leak points,release all

gas from the service port completely,and then recharge the

specified amount of refrigerant gas from cylinder.

Make sure the pipes have been connected properly.

Connect the manifod valve to the service port of the stop

valve (3- way valve) by using a charge hose.At this time,

the inside-core end of the charge hose must be connected

to the service port.

Make sure the stop valve (2-way and 3-way valve) are fully

closed. and then connect another charge hose to a vacuum

pump.

Fully open the handle Lo on the manifold valve, and then

run the vacuum pump.

Loosen the flare nut of the stop valve (3-way valve) slightly

to make sure that air is entering it.

Then, retighten the flare nut.

(If air is not entering it, make sure again the charge hose is

fimly connected to the service port.)

Cap for service port

Cap for stop valve

N.m

13.7 to 17.7

19.6 to 29.4

kgf.cm

140 to 180

200 to 300

Tightening torque

Mite

Pressar gage

Hande Hi

Charge

bose

Hande Lo

Comperad powere gage