PAGE 28 — JTNSW20-24HTCSL SERIES RIDE-ON TROWEL • OPERATION MANUAL — REV. #1 (3/24/16)

CHECKING THE DRIVE BELT

The drive belt needs to be replaced as soon as it starts to

show signs of wear.

NEVER

use a defective drive belt under

any circumstances. Indications of excessive belt wear are

fraying, squealing when in use, a belt that emit smoke or

a burning rubber smell when in use.

Under normal operating conditions, a drive belt may last

approximately 6 months. If your trowel is not reaching this

kind of life span for drive belt wear, check the drive belt for

proper pulley alignment and spacing.

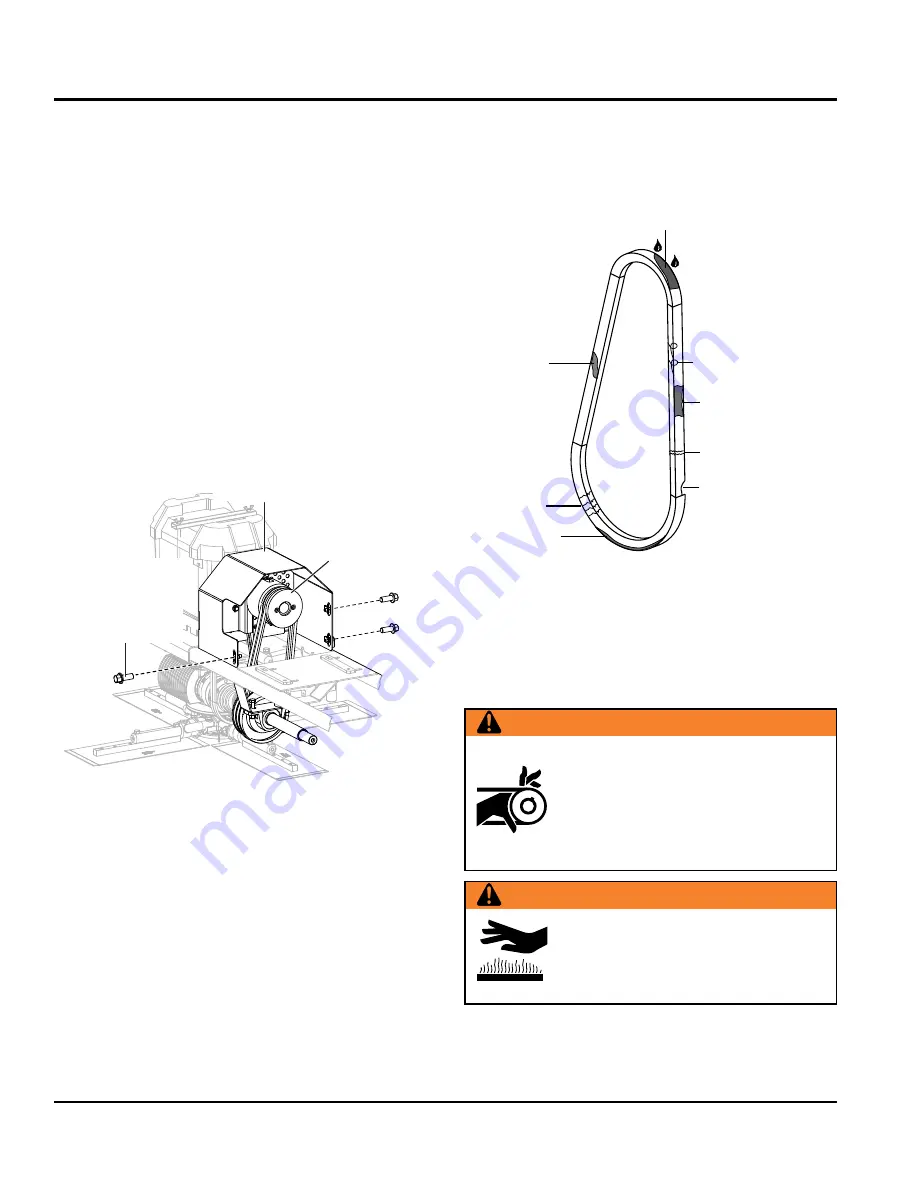

BELT GUARD REMOVAL

1. To gain access to the drive belts for inspection,

remove the 3 screws that secure the drive belt guard

(Figure 21) to the frame.

Figure 21. Drive Belt Guard Removal

REMOVE

DRIVE BELT

GUARD

REMOVE

DRIVE BELT

GUARD

SCREWS (3)

V-BELTS (2)

2. Once the belt guard has been removed visually inspect

both drive belts (Figure 22) for signs of damage or

excessive wear. If either drive belt is worn or damaged,

replace both drive belts.

Figure 22. Drive Belt Inspection

3. Check to ensure that the each belt is tensioned

correctly.

4. Finally make sure that the lower drive pulley is aligned

properly.

GLAZED

OIL SOAKED

BROKEN

CORD FAILURE

CRACKS

MISSING RUBBER

SIDEWALL

WEAR

WORN BACK

COVER

WARNING

DO NOT

attempt to insert hands or tools

into the belt area while the engine is

running.

NEVER

run the engine with the

safety guards removed. Keep fingers,

hands, hair and clothing away from all

moving parts to prevent bodily injury.

WARNING

DO NOT

remove the drive belt guard

cover until the muffler has cooled. Allow

the entire trowel to cool down before

performing this procedure.

MAINTENANCE