6

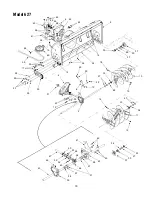

SECTION 4: ASSEMBLY

WARNING: Before installing attachment,

place tractor on a firm and level surface. Place

the PTO in the disengaged (OFF) position, set

the parking brake, shut engine off and remove

key to prevent unintended starting.

NOTE: Your tractor’s cutting deck and PTO belt must

be removed prior to mounting the snow thrower

attachment. Refer to your tractor’s Operator’s Manual

for detailed instructions. Retain all the deck hardware

and store it in a safe place. If your tractor is equipped

with any front-end accessory such as a front bumper

kit, it must also be removed.

NOTE: It is strongly recommended that a second

person act as an assistant throughout the assembly of

the snow thrower attachment. Having a second person

present eases the completion of many of the steps.

Mounting the Support Carriage Assembly

1.

Fasten the provided hex screws, belleville washers,

lock washers and lock nuts to the tractor’s front

pivot bracket as illustrated in Figure 4 on both the

left side and the right side. Do NOT tighten the

hardware at this point in the assembly.

2.

Place the tractors front tires on 2x4s to bring the

tractor’s front end up a few inches and allow

clearance for positioning the support carriage.

3.

Remove the hex screws, lock washers and hex

nuts from the both sides of the rear of the support

carriage assembly.

4.

Place the support carriage assembly between the

tractor’s front tires so that the large notch on both

sides of the support carriage straddles the tractor’s

front pivot bar. See Figure 5.

5.

Position the rear of the support carriage so that the

holes where the hardware was just removed align

with the holes in the tractor’s frame rail.

NOTE: Make certain that the support carriage is to the

OUTSIDE of the frame rail on both sides of the tractor.

6.

Reinsert the rearmost hex screw removed in Step 3

through the aligning holes in both the support

carriage assembly and the tractor’s frame rail.

Fasten with the lock washer and hex nut but do not

tighten the hardware at this time. See Figure 6.

7.

Pivot the front of the support carriage upward until

the small grooves found in the front portion of

support carriage slide between the belleville

washers inserted in step 1 and the tractor’s front

pivot bracket. See Figure 7.

Figure 4

Figure 5

Figure 6

Hex Screw,

Belleville Washer

NOTE: The lock washer and hex nut

are on the INSIDE of the pivot bracket.

Front Pivot Bar

Large Notch

Support Carriage

Hex Screw

NOTE: The lock washer and hex nut are

on the INSIDE of the tractor’s frame rail.

Содержание OEM-190-627

Страница 15: ...15 NOTES ...