DCA-180SSJU — OPERATION AND PARTS MANUAL — REV. #3 (02/01/10) — PAGE 57

1

MAINTENANCE (ENGINE)

Service Daily

If the engine is operating in very

or

conditions, a clogged air cleaner will result. This can lead to

a loss of power, excessive carbon buildup in the combustion

chamber and high fuel consumption. Change air cleaner

more

if these conditions exists.

Fuel Addition

Add diesel fuel (the grade may vary according to season

and locations).

Removing Water from the Fuel Tank

After prolonged use, water and other impurities accumulate

in the bottom of the tank. Occasionally inspect the fuel tank

for water contamination and drain the contents if required.

During cold weather, the more empty volume inside the

tank, the easier it is for water to condense. This can be

reduced by keeping the tank full with diesel fuel.

General Inspection

Prior to each use, the generator should be cleaned and

inspected for deficiencies. Check for loose, missing or

damaged nuts, bolts or other fasteners. Also check for fuel,

oil, and coolant leaks. Use Table 14 as a general maintenance

guideline

Engine Side

(Refer to the Engine Instruction

Manual)

Air Cleaner

Every 250 hours: Remove air cleaner element and clean

the heavy duty paper element with light spray of compressed

air. Replace the air cleaner as needed.

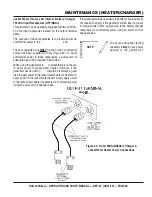

Air Cleaner with Dust Indicator

This indicator is attached to the air cleaner. When the air

cleaner element is clogged, air intake restriction becomes

greater and the dust indicator signal shows

RED

meaning

the element needs changing or service. After changing the

air element, press the dust indicator button to reset the

indicator.

TABLE 12. INSPECTION/MAINTENANCE

10 Hrs

DAILY

250 Hrs

500 Hrs

1000 Hrs

ENGINE

Check Engine Fluid Levels

X

Check Air Cleaner

X

Check Battery Acid Level

X

Check Fan Belt Condition

X

Check for Leaks

X

Check for Loosening of Parts

X

Replace Engine Oil and Filter *

1

X

Clean Air Filter

X

Check Fuel Filter/Water Seperator Bowl

X

Clean Unit, Inside and Outside

X

Change Fuel Filter

X

Clean Radiator and Check Coolant Protection Level*

2

X

Replace Air Filter Element *

3

X

Check all Hoses and Clamps *

4

X

Clean Inside of Fuel Tank

X

GENERATOR

Measure Insulation Resistance Over 3M ohms

X

Check Rotor Rear Support Bearing

X

*1 Replace engine oil anf filter at 100 hours, first time only.

*2 Add "Supplemental Coolant Addatives (SCA'S)" to recharge the engine coolant.

*3 Replace primary air filter element when restriction indicator shows a vaccum of 625 mm (25 in. H

2

0).

*4 If blowby hose needs to be replaced, ensure that the slope of the bloby hose is at least a 1/2 inch per foot, with

no sags or dips that could collect moisture and/or oil.

Содержание DCA180SSJU WHISPERWATT SERIES

Страница 2: ...PAGE 2 DCA 180SSJU OPERATION AND PARTS MANUAL REV 3 02 01 10 PROPOSITION 65 WARNING ...

Страница 69: ...DCA 180SSJU OPERATION AND PARTS MANUAL REV 3 02 01 10 PAGE 69 1 NOTES ...

Страница 72: ...PAGE 72 DCA 180SSJU OPERATION AND PARTS MANUAL REV 3 02 01 10 GENERATOR ASSY GENERATOR ASSY ...

Страница 74: ...PAGE 74 DCA 180SSJU OPERATION AND PARTS MANUAL REV 3 02 01 10 CONTROL PANEL ASSY CONTROL PANEL ASSY ...

Страница 76: ...PAGE 76 DCA 180SSJU OPERATION AND PARTS MANUAL REV 3 02 01 10 CONTROL BOX ASSY CONTROL BOX ASSY ...

Страница 78: ...PAGE 78 DCA 180SSJU OPERATION AND PARTS MANUAL REV 3 02 01 10 CONTROL BOX ASSY CONTROL BOX ASSY ...

Страница 88: ...PAGE 88 DCA 180SSJU OPERATION AND PARTS MANUAL REV 3 02 01 10 BATTERY ASSY BATTERY ASSY ...

Страница 90: ...PAGE 90 DCA 180SSJU OPERATION AND PARTS MANUAL REV 3 02 01 10 MUFFLER ASSY MUFFLER ASSY ...

Страница 92: ...PAGE 92 DCA 180SSJU OPERATION AND PARTS MANUAL REV 3 02 01 10 FUEL TANK ASSY FUEL TANK ASSY ...

Страница 100: ...PAGE 100 DCA 180SSJU OPERATION AND PARTS MANUAL REV 3 02 01 10 RUBBER SEALS ASSY RUBBER SEALS ASSY ...

Страница 102: ...PAGE 102 DCA 180SSJU OPERATION AND PARTS MANUAL REV 3 02 01 10 NAMEPLATE AND DECALS ASSY NAMEPLATE AND DECALS ASSY ...

Страница 105: ...DCA 180SSJU OPERATION AND PARTS MANUAL REV 3 02 01 10 PAGE 105 1 NOTES ...