- 7 -

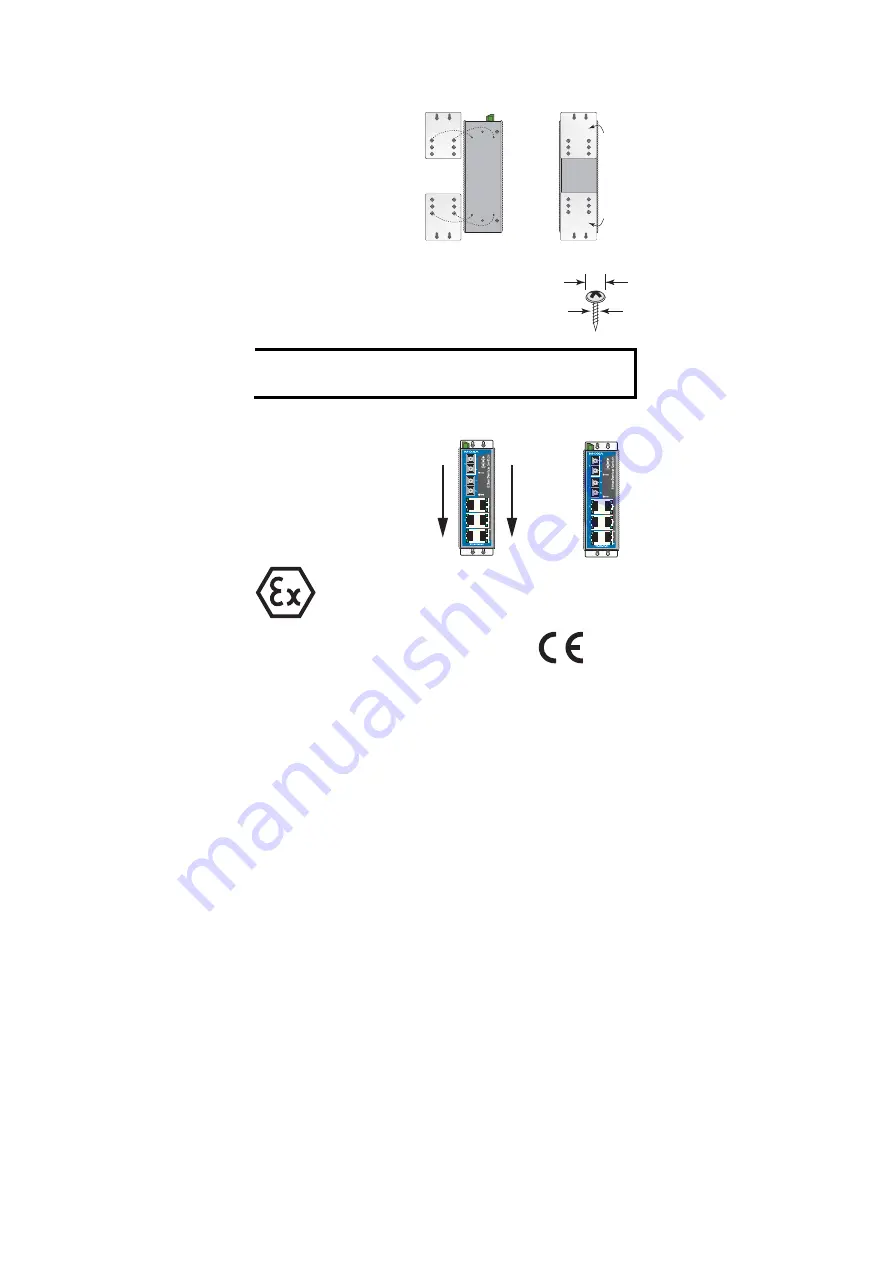

Wall Mounting (optional)

For some applications, you will find it convenient to mount the EDS on the

wall, as illustrated below.

STEP 1

:

Remove the aluminum DIN-rail

attachment plate from the

EDS’s rear panel, and then

attach the wall mount plates, as

shown in the diagram below.

⇒

top

plate

bottom

plate

STEP 2

:

Mounting the EDS on the wall requires 4 screws. Use the

switch, with wall mount plates attached, as a guide to mark

the correct locations of the 4 screws. The heads of the

screws should be less than 6.0 mm in diameter, and the

shafts should be less than 3.5 mm in diameter, as shown in

the figure at the right.

6.0 mm

3.5 mm

NOTE

Before tightening screws into the wall, make sure the screw head and

shank size are suitable by inserting the screw into one of the keyhole-

shaped apertures of the Wall Mounting Plates.

Do not screw the screws in all the way—leave about 2 mm to allow room for

sliding the wall mount panel between the wall and the screws.

STEP 3

:

Once the screws are fixed in the

wall, insert the four screw heads

through the large parts of the

keyhole-shaped apertures, and then

slide the EDS downwards, as

indicated. Tighten the four screws

for added stability.

⇒

II 3G

ATEX

Information

1.

Certification number DEMKO 09 ATEX 0812123X

2.

Ambient range (-40

°

C

≤

Tamb

≤

75

°

C)

3.

Certification string (Ex nC nL IIC T4)

4.

Standards covered ( EN60079-0:2006, EN60079-15:2005)

5.

The conditions of safe usage:

y

The Ethernet Communication Devices are to be mounted in an IP54

enclosure and used in an area of not more than pollution degree 2 as

defined by IEC60664-1.

y

A 4mm2 conductor must be used when connection to the external

grounding screw is utilized.

y

Conductors suitable for use in an ambient temperature of 93

°

C must be

used for the Power Supply Terminal.

Provisions shall be made to

prevent the rated voltage being exceeded by the transient disturbances

of more than 40%.