9/19

NT 1003-E00 09.12 AK O - AK I e

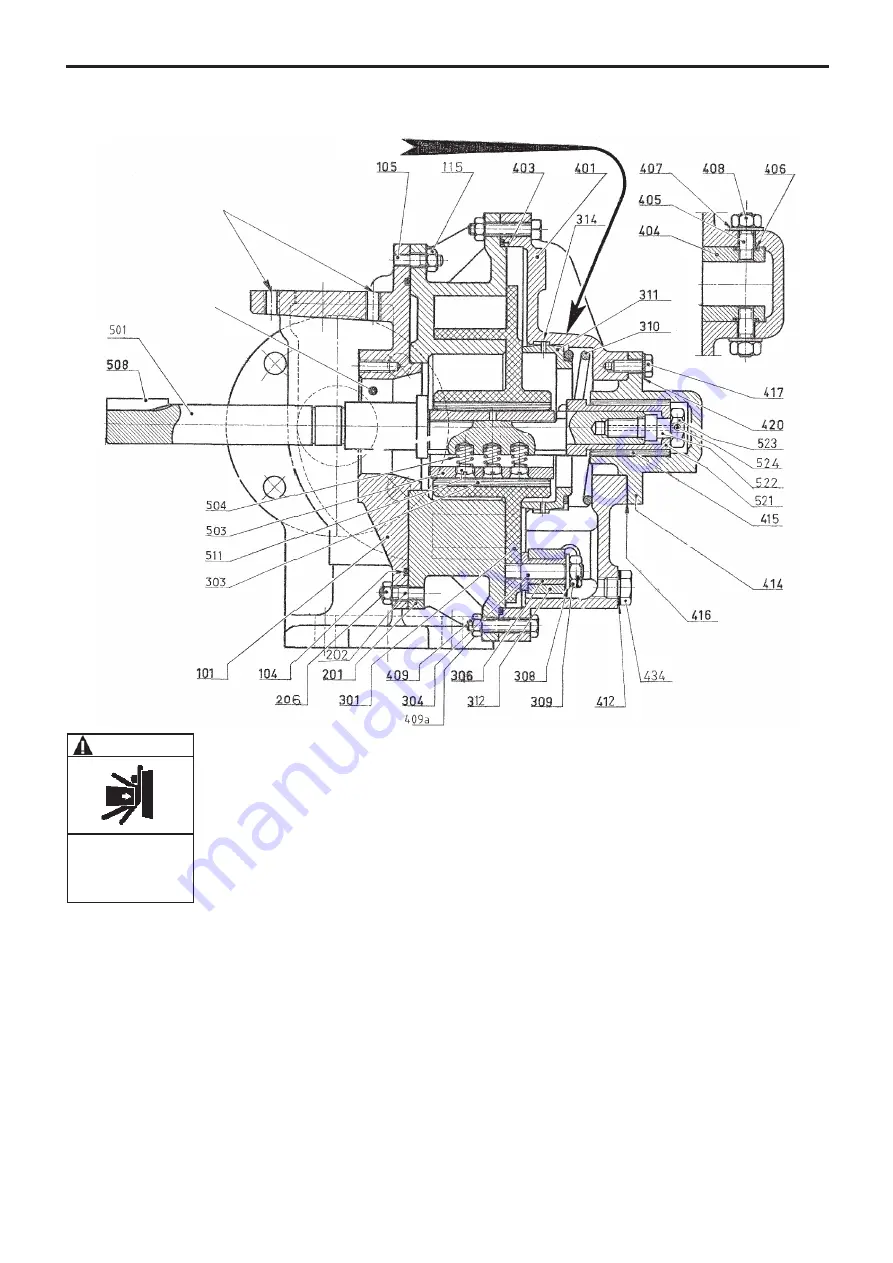

4. OPENING THE PUMP TO INSPECT

THE CYLINDER/PISTON AND BUSHINGS (continued)

Bypass fastening

For the SEALS refer to

the specified drawing

Serial Nbr

4.1 Necessary tools

• 7 - 13 - 17 - 30 open-end spanner

• 10 - 13 - 19 socket spanner

• adjustable spanner

• 1 plastic mallet

• 1 flat screwdriver

• 1 tube for assembling the bearings

4.2 Removing the front cover

Unscrew the bolts

409

and nuts

409a

securing the front cover.

Remove the front cover

401

by progressively separating

it from the pump body. Remove the seal

403

and check its

condition. Be prepared to replace it if necessary. Check

the condition of the bushing

415

. Replace it if the wear

limits have been reached (see Instructions 1003-P00).

4.3 Removing the piston and cylinder

Remove the sleeve

521

by using the nut

523

to release it.

Extract the piston

301

from the cylinder

201

(you may

have to use a lever to separate the piston from the cylin-

der. Be very cautious not damaging the piston or the cylin-

der). Examine the condition of the piston

301

and replace

it if the wear limits have been reached (see § MAINTE-

NANCE). Examine the condition of the piston bushing

303

and replace it if the wear limits have been reached (see

Instructions 1003-P00).

To dismantle the cylinder, remove the nuts

115

. Separate

the cylinder from the main body

101

and remove the seal

104

to check its condition. Replace it if necessary.

Examine the condition of the cylinder and replace it if its

wear limits have been reached (see § MAINTENANCE).

The pumping characteristics demand a cylinder/piston

with matching dimensions. Consequently, changing the

cylinder or piston requires the replacement of both the

cylinder and the piston.

4.4 Assembly of the cylinder, piston and

front cover

Assembly is done in the reverse order to the dismantling.

BE CAREFUL WITH THE WEIGHT OF

THE PARTS WHEN THEY ARE BEING

REMOVED.

WARNING

The weight ot the parts can

be dangerous and may

provoke bodily injuries or

material damages.