Leakdown Test

1.

Verify that Setup Steps 1-10 from the appropriate previous chapter have been

completed for the specific fuel system type to be tested

.

2.

Verify that the vehicle’s engine is running and check connections for leaks.

3.

Turn off the vehicle.

4.

Note the pressure reading on the unit’s

Fuel Pressure

gauge.

•

The pressure should be maintained or increased due to heat expansion.

•

On CIS systems the pressure will drop to a point then stabilize (see manufactures specifications for

this amount).

If a pressure drop occurs, this indicates a leak in the system. To isolate the leak you

will need to re-pressurize the system. Use the procedures below to re-pressurize the

system:

•

Press and hold the

Start/Run

button.

•

Turn the

Pressure Adjust

regulator clockwise until the unit’s

Fuel Pressure

gauge

displays

3/4

of the pressure noted in

Step 4

.

•

Release the

Start/Run

button.

•

Press the

▬

button to decreases the time until the

Time

LED displays five

minutes.

•

Press the

Leak Test

button on the unit’s control panel.

Use the procedure above to re-pressurize the system whenever there is significant

drop in pressure during the Leakdown test.

Once you have re-pressurized the system, use the procedures below to isolate the leak.

•

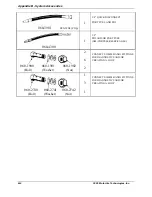

Locate the pressure line adaptor closest to the T-adaptor (#060-4500) and the vehicle’s fuel tank.

Bend the pressure line adaptor in half and squeeze tightly. If the pressure stabilizes, this indicates a

leak in either the pressure fuel line or a bad one-way check valve in the vehicle’s fuel pump.

•

Locate the return line adaptor close to the pressure regulator. Bend the return line adaptor in half and

squeeze tightly. If the pressure stabilizes, this indicates a leak in the vehicle’s pressure regulator.

This problem is generally dirt-related and should be resolved by the cleaning process. However, if

fuel is present in the vacuum line from the regulator, this indicates a leaking diaphragm.