headline bars

tabs

continuation tabs

notes

warnings

headline bars

tabs

con

tinua

tion tabs

not

es

w

ar

nings

headline bars

tabs

continuation tabs

notes

warnings

model no. 009-0078-8 | contact us 1-888-942-6686

6

ASSEMBLY

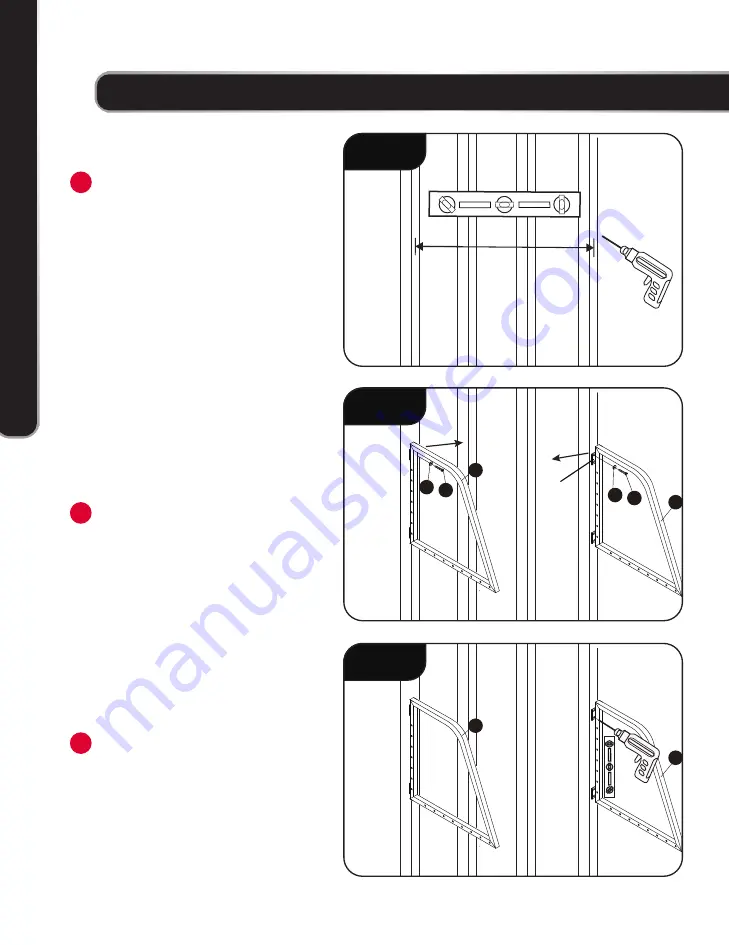

Plan for the proper location of the tire

rack. The product must be attached to a

wall surface with vertical studs, and the

supports will be positioned 48” (121.9

cm) (centre to centre) apart. Use a stud

finder (not included) to assist in locating

studs. Use a pencil to mark the top

mounting hole centres. Make sure holes

are level. Pre-drill the marked holes

using a 3/16” (4.8 mm) drill bit.

Note:

the tire rack must be mounted

directly into the wall studs; do not use

wall anchors to mount to sheetrock.

Note:

make sure the pilot holes that

pre-drilled are long enough, at least

longer than the lag screws provided.

Slide Washer (6) onto the Lag Screw

(5); insert Lag Screw (5) through the top

mounting hole of each Frame to hold

in place using a 13mm wrench (not

included). Do not tighten Lag Screw (5)

completely at this time.

Note:

Identify Left Frame or Right Frame

using the marking sticker on each,

make sure the Mounting Plates are to

the inside.

Note:

Don’t use an impact driver.

Make sure Left Frame (1) and Right

Frame (2) are vertically level using a

level. Use the remaining 3 mounting

holes in each as template, and drill the

holes on the wall studs.

1

3

2

ASSEMBL

Y

x

STEP 1

x

48” (centre to centre)

STEP 2

1

6 5

2

6 5

Mounting

Plate

STEP 3

1

2