The Specialist In Drum Handling Equipment

Model 405-114

Omni-Lift Karrier

Operator’s Manual for Morse Omni-Lift Karrier Model 405-114

Serial Number 0617 to ____ (MMYY)

morsedrum.com

Copyright 2019 - Morse Mfg. Co., Inc.

Form OM405-114 (0617-____)

(Updated June 12, 2019 3:30 PM)

4

Operating Instructions

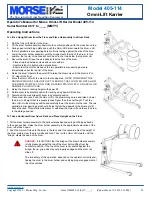

To Lift an Upright Drum from the Floor and Place Horizontally in a Drum Rack

Roll the Omni-Lift Karrier to the drum.

1.

Tilt the drum holder assembly down into the vertical position with the cross bar on top.

2.

Swing open ratchet hinge plate and push the Omni-Lift Karrier oward the drum, until

3.

the two parallel drum-supporting bars are firmly resting against the side of the drum.

Lower the drum holder assembly until the bridge meets the top of the drum. In this

4.

position, the top rim chine hooks should be an inch or two below the top drum rim.

Secure the drum: Drape the web strap across the face of the drum.

5.

- Place strap loop between clevis and secure with pin.

- Operate ratchet to tighten strap around drum.

- Ensure that the chime catches on the two parallel drum-supporting bars are

immediately under the top rim of the drum

Raise the drum: Operate the power lift to raise the drum only until the drum is 6” to

6.

12” clear of the floor.

Move the Omni-Lift with the drum to the racking area.

7.

NOTE: TRANSPORT THE

DRUM UPRIgHT AT A HEIgHT JUST CLEAR OF THE FLOOR. DO NOT ALLOW

THE DRUM TO IMPACT ON FLOOR, RACKINg STATION, ETC. OR A SPILL OR

DAMAgE COULD OCCUR.

Raise the drum to racking height with power lift.

8.

Rotate drum to horizontal position for racking using power tilt function.

9.

Disconnect the web strap with drum in horizontal position.

10.

Place drum into rack: Push the Omni-Lift to the drum storage area and raise or lower

11.

the drum to a height that is a couple inches higher than the shelf height. Push the

Omni-Lift into the storage position and carefully lower the drum onto the rack. The two

parallel drum-supporting bars should be just below the sidewall of the drum but still

above the rack. This will allow clearance to withdraw the Omni-Lift and leave the drum

in the storage position.

To Take a Horizontal Drum from a Rack and Place Upright on the Floor

1. Tilt the drum holder assembly to the horizontal positionand swing both hinged bands

to the open position. Raise the drum holder assembly to the approximate elevation of the

drum to be taken down.

2. Push the Omni-Lift close to the drum in the rack and, if necessary, adjust the height of

the drum grab to clear the drum walls and rack. Then roll the Omni-Lift forward until the

“bridge” meets the head of the drum.

DANGER

- It is CRITICAL that the bridge of the drum holder assembly

is fully pressed against the top of the drum before lifting from the

horizontal position. If the top of the drum is not seated against the

bridge, the rim grip pads may not properly engage and the drum can

slide off.

The true safety of this operation, depends on the operator correctly posi-

tioning the drum in the drum holder, and verifying proper engagement of

the chine catches.